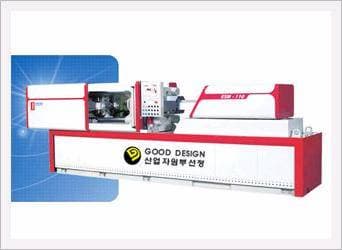

Injection Molding Machine (ESM Series)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Apply a video call to the Supplier

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | Injection Molding Machine (ESM Series) | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Descriptions

High performance electric motor type Injection Molding Machine with precision and repeatability

ESM Series has high energy savings effect using servomotor and can be used for mass production of thin wall precision products through compoun drive while it is optimum model for the production of high precision products through the improvement of high responsiveness and repeatavility.

- Realized high injection pressure and infinite packing time

- Reducing the weight of product through accurate pressure, speed and position control

- Increase of energy saving effect

- Possible for molding for complicated structures and thin wall molding

- Realized clean working environment

- Reduction of cycle through compound simultaneous movement

Application field

Suitable for the production of thin wall precision products which require high injection pressur and speed and optical products which require clean working environment and dimension precision.

Clamping Unit

- Possible to maintain optimum state of driving unit through direct detection of lubrication state of toggle system by motor.

- Protection of Mold : Realized perfect mold protection wighout sptarate detection device for mold clamp driving axle.

- Use of mold with hydraulic core

- Mold clamp force detection fuction during machine operation-Automatic calibration

Injection unit

- Realzed remarkable holding pressure power and holding time though non-linerar system

- Possible to use holding pressure and holding time without limitation

- Possible to use exisiting (Hydraulic type) mold without limitation

- Application of non-linear system for Crank-Slider mechanism

- Simplification of reduction gear and the enhancement of responsiveness

- Improvement of the degree of precision for position control through unification of mechanism and programs

- Screw design which is suitable for eletric injextion Machine

- Melting fusion and mixing milling of resing in high speed cycle

Other

- Serbo-drive

- Application of high performance multi-axail servo-drive

- Closed Loop control for pressure speed and position

- Increase of energy saving effect(50% saving vs hydraulic type)

- Use recharged reverse current based on inertia

- Maximize energy saving effect by mountin inverter at the hydraulic driving unit

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

,_Smartphone_dryer,_heating_mobile_2.jpg)