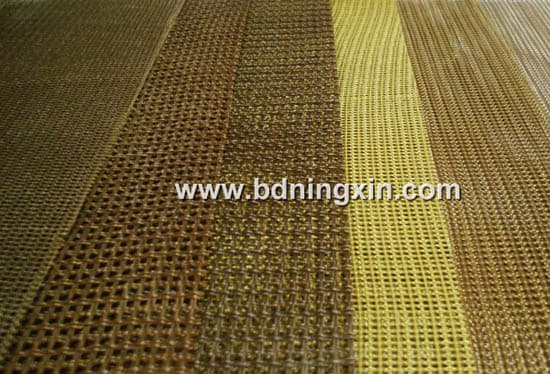

High silica mesh fiberglass casting filter

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- casting filter, fiberglass filter, high silica, silica mesh

- Category

- Industrial Supplies

Apply a video call to the Supplier

Baoding Ningxin New Material Co.,Ltd.

- Verified Certificate

-

11

| Product name | High silica mesh fiberglass casting filter | Certification | - |

|---|---|---|---|

| Category | Industrial Supplies | Ingredients | - |

| Keyword | casting filter , fiberglass filter , high silica , silica mesh | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- DN C

- Address

- Baqie Industrial Zone,Baoding,Hebei,China

- Product Category

- Industrial Supplies

- No. of Total Employees

- 101-500

- Company introduction

-

Baoding Ningxin is specially dedicated to manufacturing molten metal filters since 2002. We offers a complete range of foundry filter products and services. The product ranges from very cost effective fiberglass mesh filter to high filtration efficiency ceramic foam filter.Our company is ISO9001:2008 certified and products had been passed the authorized inspection in China. Being the first mass production manufacturer of silica mesh casting filter in China,we have our patented technologies and facilities to supply the state of art mesh filters.In recent years,we also positively develop the ceramic filters based on different material to meet various demand of foundries. Our foundry filter lines are as follows: -Aluminum filtration cloth filter in rolls,cut pieces or special shapes like cap,tubular or funnel etc. with or without resin coating or after non-smoke process. -High silica fiberglass mesh filters for iron and small scale steel castings,in cut pieces or special cup shapes. -Silicon carbide ceramic foam filters for iron and copper casting filtration. -Alumina ceramic foam filters for foundry or cast house filtration with size up to 23"x23"x2". -Zirconia ceramic foam filters for steel casting filtration. -Extruded ceramic filters for aluminum and iron filtration. We are serving more than 2,000 foundries in China now and had started overseas marketing since 2010.We aim to offer you top quality products and services and we sincerely hope that we can eastablish the fine cooperation with you.

- Main Markets

-

China

China

Italy

Italy

South Korea

South Korea

U.S.A

U.S.A

- Main Product