Alumina Plate Silicon Carbide Plate

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- alumina plate, ceramic plate, silicon carbide plate

- Category

- Electronic Products , Mugs

Apply a video call to the Supplier

Xiamen Innovacera Advanced Materials Co.,LTD

- Verified Certificate

-

12

| Product name | Alumina Plate Silicon Carbide Plate | Certification | - |

|---|---|---|---|

| Category |

Electronic Products

Mugs |

Ingredients | - |

| Keyword | alumina plate , ceramic plate , silicon carbide plate | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

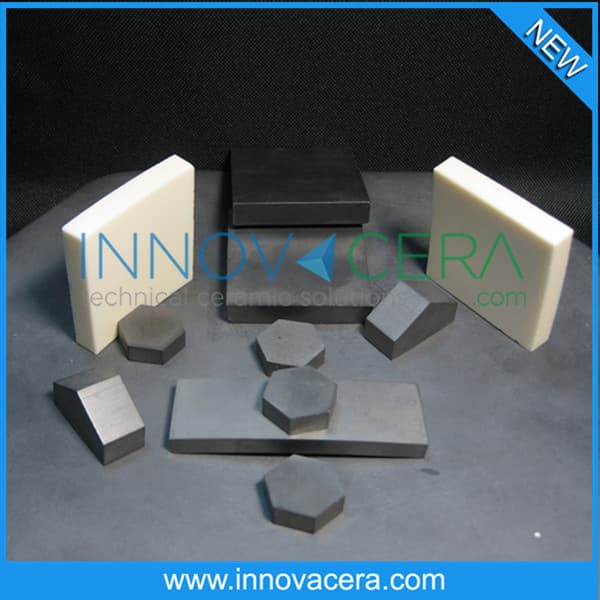

Alumina Plate & Silicon Carbide Plate/Innovacera

Innovacera supply High Performance Lightweight Materials for Composite Armor Systems, includeBallistic Body Armor, Vehicle Armor, Armored Car, Aircraft Armor, etc. Our products are exported to Germany, ISRAEL, Serbia, India, Thailand, Singapore, South Africa, etc.

We are a leading and biggest researcher and manufacturer of alumina ceramics in China,our products are very popular with customers from many countries all over the world,we will always offer your ceramics with high quality,high density,high hardness,accurate size and also we could delviery very fast.

Hexagon Tiles

Rectangle Tiles

Curved Rectangle Tiles

Single Curved Plates

Material:

Alumina 99(99% Alumina)

Sintered Silicon Carbide(SSiC)

Boron Carbide(B4C)

Sizes:

50*50mm;100*100mm;50*25mm;100*50mm etc. and OEM

Ballistic level:

NIJ4 Standard-0101.04, NIJ IV Lever,NIJ III LEVER

Applications:

Sintered Silicon Carbide Plates

SSiC is a fully dense material that can be produced in a cost effective manner such as dry pressing, and isostatic pressing, to complex net shapes. This grade of silicon carbide is characterized as exhibiting both hardness and toughness.

Innovacera provides ceramic armor plates protection systems using high-performance, lightweight materials for armor protection applications. Innovacera offers Silicon Carbide armor plate in a variety of shapes and sizes. We have various imperial and metric measurements in square or hexagon shapes or you can select custom shapes and thickness.

Boron Carbide Plate

Boron carbide is known as a robust material having high hardness, high cross section for absorption of neutrons (i.e. good shielding properties against neutrons), stability to ionizing radiation and most chemicals. Its Vickers hardness (38 GPa) and fracture toughness (3.5 MPam1/2) approach the corresponding values for diamond (115 GPa and 5.3 MPam1/2).

Boron carbide plate are used to produce multi-hit tactical body systems by means of boron carbide and silicon carbide advanced technical ceramics.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Qiurong Chen

- Address

- RM615,NO.398 Jiahe Rd,Huli district,Xiamen ,Fujian Province,361009 China

- Product Category

- Ceramics,Electroceramics,Refractory

- Main Product

Related Products

QVIA DASH CAM AR790 / FHD Dash Cam / Car DVR / Black Box

Ostrich diary case for Smart Phone Korea

Portable Hydrogen Water tumbler BlueWater700M-PEM technology

_2.jpg)

Mixing Amplifier (SMA-1202A)

Cafe Specialty A1_SELF-SERVE HOT & ICED CAFE MACHINE with various cashless payment system

China

China