Amorphous Graphite Briquette

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Graphite Products

Apply a video call to the Supplier

South Graphite Co.,Ltd

- Verified Certificate

-

10

| Product name | Amorphous Graphite Briquette | Certification | - |

|---|---|---|---|

| Category | Graphite Products | Ingredients | - |

| Keyword | amorphous graphite , graphite briquette , natural graphite , heat elevating matrail | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 2504902000 |

Product Information

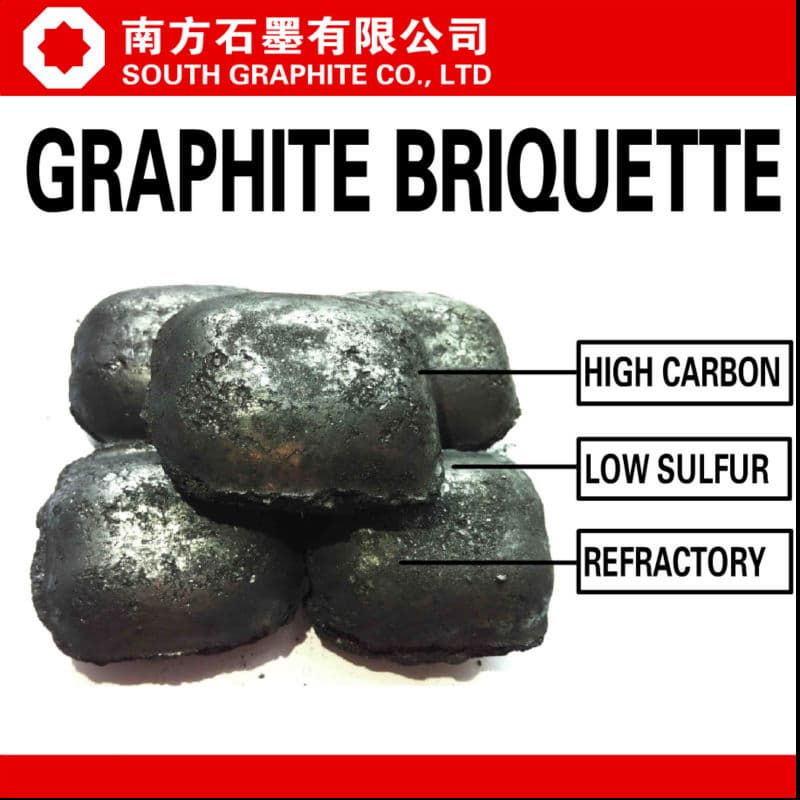

Natural Amorphous Graphite Briquette

FC: 75%min, 78%min, 80%min,

SUL: 0.05%max, 0.07%max,0.1%max, 0.15%max, 0.2%max, 0.3%max, 0.5%max

Moisture: 2.0%max

Size: 50mm50mm30mm 48mm38mm24mm

And we can produce the product according to customers' requirement.

We produce natural amorphous graphite briquette of amorphous graphite ore material of lutang, in chenzhou of china, where there is the biggest and best amorphous graphite deposit all over the world.

The natural amorphous graphite briquette is widely used in steel and iron making, used as recarburizer, insulating agent, protective slag, and so on.

If you have any interest in our products please feel free to contact us, we will give you our best service.

You are welcome to visit our company for investigation and purchase.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Zijian Hu

- Address

- 5/F, Linyi Fortune Center, Wuling Square

- Product Category

- Graphite Powder,Other Graphite Products

- No. of Total Employees

- over 2000

- Company introduction

-

Founding Background In November of 2010, People's Government of Hunan Province had built a strategic partnership and deep collaboration with China National Building Material Group Corporation, which is China central enterprise, directly under the State-owned Assets Supervision and Administration Commission. To speed up the process of new industrialization in Chenzhou city and promote local economic development,a strategic cooperation framework agreement on building up China's largest graphite industrial base has been signed by Mr. Xiang Lili , Mayor of Chenzhou Municipal Government and Mr. Cao Jiang-Lin, the director and president of CNBM. Ⅰ、Introduction of SOUTH GRAPHITE CO.,LTD In March of 2011, South Graphite Co., Ltd. is incorporated in Chenzhou City, Hunan Province, China, with registered capital of 1 billion yuan. South Graphite Co., Ltd., as a resource investment platform of CNBMI, is committed to actively promote the consolidation of graphite industrial resources and technological progress, and carry out a comprehensive consolidation and integration of graphite resources in the areas of Lutang Town and Heye , Taihe, Qinghe village (referred to as “Lu He Tai Qing mining area”) of Chenzhou city, to make the graphite business in Chenzhou area stronger、better and bigger and further lead healthy and sustainable development of the graphite industry. South graphite planned to have the capacity of 2.07 million tons annually,of which,11 coal mines can produce 1.56 million tons/year, 9 graphite mines 510 thousand tons/year. The next three years, South Graphite will invest 3 billion to build up the fine and deep processing chain of graphite, make the radical improvement in graphite industry of Chenzhou. Ⅱ、Production Base—LUHE TAI MINING AREA The ore production base of South Graphite Co., Ltd. is located in Lu He Tai mining area in Chenzhou city, Hunan Province. It’s only 50 KM from Chenzhou downtown. The mining area stretches from north-south about 20KM, and with the width of 2.15 km on average from east-west. Its total area is around 45 square kilometers. In 1985, the State Geological Bureau proved the mining reserves of 34.07 million tons of graphite, which consisted of 72.5% of total proven reserves of amorphous graphite in China. The products in Luhe Tai mining area is high-grade mineral. Containing 80% fixed carbon on average, 92% on highest. It is well known for good quality. According to estimation recently, the mining reserves of 25.151 million tons of coal and 12.469 million tons of graphite in the scopes which have mineral rights. Outside the scopes which have mineral rights, detailed investigation has reached 8.87 million tons of coal reserves, 5.12 million tons of graphite reserves. And forecast that the mining reserves of 16.33 million tons of coal, 9.53 million tons of graphite in the deep mining area. Ⅲ、Deep processing & R&D Base South Graphite Co., Ltd plans to invest 3 billion yuan in the next three years, building a national Graphite Industrial Park in Chenzhou City, which will cover 200 hectares, consisting of graphite processing, research and development, trade and logistics. Initial stage the industrial park covers an area of 100 mu and the factory building area is about 20,000m2. Currently the industrial park has carbon briquette production line, which the annual output of 300,000 tons; granular graphite production line, which the annual output of 150,000 tons;and graphite powder production line that annual output of 50,000 tons. Ⅳ、Product Introduction Carbon briquette Carbon briquette, is made of shattered graphite ore, by dosing, grinding, extrusion, drying and a series industrial process, then being a globular structure which has a certain intensity. They are used as ingot protectants in steel industry. FC: 70%-90%; graphite ore has low sulphur and high-grade . Size: mainly 45×38×25mm、45×45×20mm、30×25×20mm、25×20×16mm ,also according to customers demand. Granular graphite Granular graphite has a granular structure, appearing silver gray or black which is made of screened graphite ore. It is mainly used for steel carbon, refractory materials, high-temperature material, electrode paste, etc. FC: 60%-90%; graphite ore has low sulphur and high-grade . Grain size: mainly 0-3mm、0-6mm、0-15mm、1-5mm、2-5mm、1-6mm , also according to customers demand. Graphite powder Graphite powder is the powder form of processed graphite ore which appears gray black. It's mainly used for pencils, batteries, electrical carbon electrode, graphite bearing, casting material, refractory material, dyestuff and lubricating material. FC: 60%-90%, graphite ore has low sulphur and high-grade . Size: mainly 80mesh 、100 mesh 、150mesh 、200mesh 、325mesh, also according to customers demand. Casting Graphite Specification: Classified by total of 8 levels as 60, 65, 70, 75, 78, 80, 83 and 85 according to the content of Fixed Carbon. The particle size of Graphite Powder is classified by 3 levels as 45, 75, 150um (the same as -325mesh, -200mesh and -100mesh ). Different specifications could be ordered by different demands. Usage: Casting Industry. When graphite was coated on the surface of the solid, the surface would form a smooth and hard film which has a good coating performance as Casting Remover. Brushing amorphous graphite powder on the surface of the wet-sand mould by banister brush, then the surface of the pouring stuff would be very smooth, and the air voids of the surface would be stuffed with graphite powder, the iron liquid would not be easily penetrating into sands which has a clean and tidy surface of the casting stuff instead of adhering sand casting. Oil drilling graphite Our oil drilling graphite powder has excellent lubrication, so can effectively reduce torque, wear and fatigue of the drilling, to extend the entire life cycle of the bit bearing. And also able to reduce the frictional resistance of the drill string, shorten the trip time; and prevent stuck, bit balling. The graphite powder can be strongly adsorbed in drilling tool and side wall, so as to improve the state of the friction between the friction pair, to play a role in reducing friction. Meanwhile, graphite powder adsorption in the side wall, the side wall microvoid can be closed, so can achieve double effects on reducing the filtration of drilling fluid and protecting reservoirs.

- Main Markets

-

Germany

Germany

Iran

Iran

Italy

Italy

Japan

Japan

Netherland

Netherland

South Korea

South Korea

U.S.A

U.S.A

- Main Product

Related Products

Carbon Graphite Parts For Vacuum Furnace

Graphite Ignot.

sell Graphite Electrode Scrap

TSG Series

gold melting induction furnace graphite crucible

China

China