Exothermic Anti piping Compound to feed material

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- JNY

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Apply a video call to the Supplier

Henan Jinnaiyuan New Materials Tech. Co., Ltd.

- Verified Certificate

-

9

| Product name | Exothermic Anti piping Compound to feed material | Certification | - |

|---|---|---|---|

| Category | Other Non-Metallic Mineral & Products | Ingredients | - |

| Keyword | anti piping compound , heat generating agent , hot top powder , riser heat insulation covering agent | Unit Size | - |

| Brand name | JNY | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

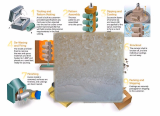

Exothermic Anti piping Compound

Product Description:

Exothermic Anti-piping Compound is used in foundries after pouring, to maintain the molten metal temperature in the upper part to stay nearly the same as the lower layer, and prevent piping defect in the casting.

Due to teh temperature of molten metals, Exothermic Anti-piping Compound will burn and provide reservoir od liquid metal for solidification (liquid contraction) during cooling process. After burning, an insulating layer will form to decrease heat loss. Cavities resulted from shrinkage will become more curve-like (U-shaped), instead of funnel-like(v-shaped).

Features:

1.High calorific value, outstanding performance on temperature insulation. It can keep high temperature of liquid steel in riser area to ensure continuous replenishment of hot steel, which ensure compact texture without shrinkage and osteoporosis to increase the finishing rate of castings.

2.When using this product, the riser would contraction with U-shape on the top, which can save 30%-50% hot steel on the riser to maximum increase the finishing rate.

Specification:

Main Chemical Composition%

| SiO2 | Al2O3 | Fe2O3 | CaO | R2O |

| 10-13 | 10-13 | 12-15 | 11-14 | 15-18 |

Physical Properties

| Melting Point°c | Expansion rate% | Granularity mm | Moisture% |

| ≥1600 | 1.9-2.9 | <5.0 | <0.02 |

Use Method:

After pouring, apply the compound on the surface of molten metals through sprue and riser/feeder head. The compound will react with molten metals and start burning to supply heat.

Application:

Grey Iron/ Nodular (Ductile) Iron, Stainless Steel/ Alloy Steel.

Note:

Store the compounds in a dry, cool and shady area and away from any sources of heat, flame or anything that may produce sparks.

Any problems, please do not hesitate to contact me.

International Trade Dept.

HENAN

JINNAIYUAN NEW MATERIAL TECHNOLOGY CO.,LTD

Add: High

Tech Development Zone, Zhengzhou, Henan.

TEL/FAX:

86-371-86593285

Mobile: 0086 15890108206

Skype:

liyinghuilijie

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Pangyousheng

- Address

- High-Tech Development Zone, Zhengzhou, Henan

- Company introduction

-

Henan Jinnaiyuan New Material Tech. Co., Ltd. was founded in 2005 with nearly 200 employees, which produces new materials for metallurgy and casting, combining production, sales and service in one. Our company attaches more importance to scientific and technological innovation; we are fully committed to the R&D of new technology and materials with "market-oriented, customer satisfaction as our object".

We produce nearly hundred kinds of products which belong to more than a dozen series, covering foundry spherical ceramic sand, coating, refractory castable, deslagging agent, cover agent, recarburization agent, resulfurization agent and desulfurization agent, etc. The main property indicators of our products have reached or exceeded the similar imported products and some products have been filled the blank of the industry. Our products are widely used in high-end foundry and enjoy good reputation in domestic market.

Our company has an experienced technical and management team, advanced production technology, technical equipment and perfect detection methods, which can provide customers with high quality products and services.

Our company has always been adhering to the core values of "character made products" and put forward the business philosophy of "real life" , "tangible products" and "full services". We are sincerely looking forward to cooperating with you and hand in hand to create our brilliance.

- Main Product

Related Products

Soapstone Chalk,Soapstone Sticks

Cristobalite calcined silica powder

Calcium Aluminate Synthetic Slag For Metallurgical Flux

Ceramic Valve Seats

fused silica investment casting Grade

China

China