Laser Welding Machine_LWI V Flexx

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Germany

- Brand name

- Vision Lasertechnik GmbH

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Industry Laser Equipment & Parts

Apply a video call to the Supplier

Vision Industries Korea LLC.

- Verified Certificate

-

9

| Product name | Laser Welding Machine_LWI V Flexx | Certification | - |

|---|---|---|---|

| Category | Industry Laser Equipment & Parts | Ingredients | - |

| Keyword | laser welder , laser welding machine , laser welding system , laser welding equipment | Unit Size | 880.0 * 730.0 * 538.0 mm |

| Brand name | Vision Lasertechnik GmbH | Unit Weigh | - |

| origin | Germany | Stock | - |

| Supply type | - | HS code | 851580 |

Product Information

The versatile workstation for individual customisation or integration

Over 1000 installed LWI series systems stand for excellent performance and reliability.

In a simple and dynamic design, the series V laser head has all the standard features that make work in fields such as tool-making and moulding-making, precision mechanics and sensor technology simple and easy.

For all other applications where the standard version is not enough, we have optional packages at the ready for special and specialised applications. These include, for example, special sets for energy stabilisation and spot sizes in the µm range for microelement production applications in medical and microsensor technology.

No matter what your current requirements, our LWI V Flexx system will provide the basis you need with the option of almost any technical extension. Our system is already equipped now for the applications of the future.

If you cannot find the option you are looking for in our range of accessories, simply contact us. We enjoy solving your application needs.

T-slot nuts in the ultra-stable basic profile ensure easy connection of the laser head to your systems.

Each laser has multiple sensors that monitor operation and display errors in plain text. The modular design means repairs are rapid and inexpensive, and ensures a supply of spare parts long after the set statutory period.

We are still supplying all spares for series I, still in use at our clients’ sites worldwide after more than 20 years.

Highlights

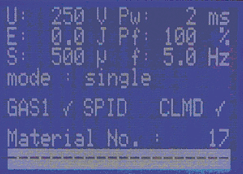

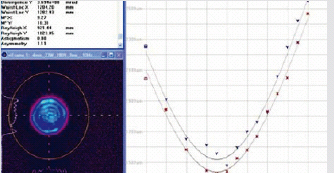

Display, operating, integrated energy measuring

The ergonomically arranged display and terminal located closley behind the microscope give you a direct view of all the important operating parameters. The integrated energy measuring system indicates the emitted energy after every laser pulse and therefore enables the monitoring of the welding process as well as the precise adjustment of the pulse energy.

Programmable shielding gas post-flooding

In order to eliminate the oxidation of the welded joint directly after it has been welded, the times during which the shielding gas ist still conducted on the welded joint following the welding can be individually set.

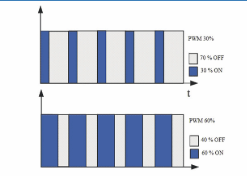

PWM mode

In the lower power range, which depends upon high stability, traditional lasers are inclinined toward a low „pulse to pulse stability“ and thus to a non-uniform welding result. The Pulse Width Modulation (PWM) gives a vastly more fine and stable coordination, as the internal energy supply here works in the area of the optimal output.

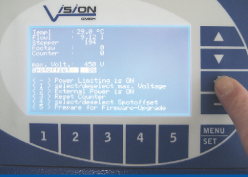

Service, diagnosis and upgrade

With the integrated selfdiagnostic system, you have the opportunity to detect faults in ongoing operations and to display this as plain text in a message. Even the laser's own software undergoes constant further development: you can bring your device up to date with a firmware upgrade.

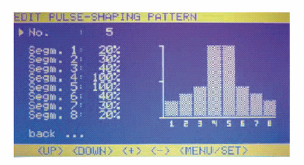

Pulse shaping

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Ingeun Choi

- Address

- 22-1, Siheung-daero 935beon-gil, Siheung-si, Gyeonggi-do 14956, Korea

- Product Category

- Industry Laser Equipment & Parts

- Company introduction

-

Global Laser welding & marking machines

- Main Markets

-

Brazil

Brazil

Thailand

Thailand

Viet Nam

Viet Nam

- Main Product

South Korea

South Korea