Pressure Purposes EN10217-7 Stainless Steel Tubes With Autom

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Torich

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Stainless Steel

Apply a video call to the Supplier

Torich International,.Ltd

- Verified Certificate

-

9

| Product name | Pressure Purposes EN10217-7 Stainless Steel Tubes With Autom | Certification | - |

|---|---|---|---|

| Category | Stainless Steel | Ingredients | - |

| Keyword | welded steel tubes , round steel tubes , stainless steel tubs , pressure purposes steel tubes | Unit Size | - |

| Brand name | Torich | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

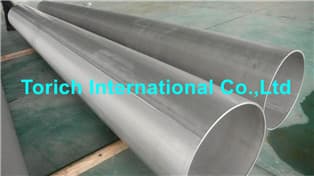

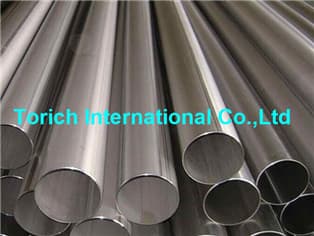

EN10217-7 Welded steel tubes for pressure purposes - Technical delivery conditions -

Part 7: Stainless Steel Tubes

Manufacture:

The tubes are manufactured from hot or cold rolled plates, sheet or strips in accordance with EN10028-1,

longidudinally arc or laser welded by fusion accross the abutting edges

Manufacturing process

- Automatic arc welding

- Laser welding

Delivery condition:

| Symbol | Types of delivery condition | Suface Condition |

| W0b | Welded from hot or cold rolled plate, sheet or strip 1D, 2D, 2E, 2B | As welded |

| W1b | Welded from hot rolled plate, sheet or strip 1D, descaled | Metallically clean |

| W1A b | Welded from hot rolled plate, sheet or strip 1D, descaled | Metallically clean |

| W1R b | Welded from hot rolled plate, sheet or strip 1D, bright annealed | Metallically bright |

| W2 b | Welded from cold rolled plate, sheet or strip 2D, 2E, 2B descaled | Metallically clean |

| W2A b | Welded from cold rolled plate, sheet or strip 2D, 2E, 2B, heat treated,descled | Except for the wel, essentially smoother than for types W1 and W1A |

| W2R b | Welded from cold rolled plate, sheet or strip 2D, 2E, 2B, bright annleaed | Metallically bright |

| WCA | Welded from hot rolled or cold rolled plate, sheet or strip 1D, 2D, 2E, 2B, heat treated if appropriate, at least 20% cold formed, heat treated, with re-crystallized weld metal, descaled | Metallically clean, welded scarcely recognizable |

| WCR | Welded from hot rolled or cold rolled plate, sheet or strip 1D, 2D, 2E, 2B, heat treated if appropriate, at least 20% cold formed, bright annealed, with re-crystallized weld metal | Metallically bright, welded scarcely recognizable |

| WG | Ground c | Metallically bright-ground, the type and degree of grinding shall be agreed at the time of enquiry and order |

| WP | Polish c | Metallically bright-polish, the type and degree of polishing shall be agreed at the time of enquiry and order |

EN10217-1 Part 1: Non-alloy steel tubes with specified room temperature properties

EN10217-2 Part 2: Electric welded non-alloy and alloy steel tubes with specified elevated

temperature properties

EN10217-3 Part 3: Alloy fine grain steel tubes

EN10217-5 Part 4: Electric welded non-alloy steel tubes with specified low temperature

properties

EN10217-5 Part 5: Submerged arc welded non-alloy steel tubes with specified low

temperature properties

EN10217-6 Part 6: Submerged arc welded non-alloy steel tubes with specified low

temperature properties

EN10217-7 Part 7: Stainless steel tubes.

Normative References:

EN 473, Destructive tests - Qualification and certification of NDT personnel - General principles

EN 910, Destructive tests on weld in metallic materials - Bend test

EN1321, Destructive tests on welds in metallic materials - Macroscopic and microscopic examination

of welds

EN10002-1, Metallic materials - Tensile testing - Part 1: Method of test at ambient temperature

EN10002-5, Metallic materials - Tensile testing - Part 5: Method of tesing at elevated temperature

EN10020, Definitions and claasification of grades of steel

EN10021, General techical delivery requirements for steel and iron products

EN10027-1, Destructive systems of stels - Part 1: Steel names, principle symbols.

EN10027-2, Designation systems for steels - Part 2: Numerical systems.

EN10045-1, Metallic materials - Charpy impact test - Part 1: Test method

EN10052, Vocabulary of heat treatment terms fo ferrous products

EN10204, Metallic products - Types of inspection documents

EN10200, Seamless and welded steel tubes - Dimensions and masses per unit length

EN10233, Metallic materials - Tubes - Flattening test

EN10234, Metallic materials - Tubes - Drift expanding test

EN10236, Metallic materials - Tubes - Rings expanding test

EN10237, Metallic materials - Tubes - Ring tensile test

EN10246-1, Non-Destructive Testing of steel tubes Part 1: Automatic electromagnetic testing of

seamless and welded ( except submerged arc welded) ferromagnetic steel tubes for

verification of hydraulic leaktightness

EN10246-3, Non-Destructive Tesing of steel tubes - Part 3: Automatic eddy current testing of seamless

and welded ( except submerged arc-welded) steel tubes for detection of imperfections.

EN10246-5, Non-Destructive Testing of steel tubes - Part 5: Automatic full peripheral magnetic

transducer/flux leakage testing of seamless and welded (except submerged ard-welded)

ferromagnetic steel tubes for the detection of longitudinal imperfections

EN10246-6, Non-Destructive Tesing of steel tubes - Part 6: Automatic full peripheral ultrasonic testing of

seamless steel tubes for the detectiong of transverse imperfections.

EN10247-7, Non-Destructive Testing of steel tubes - Part 7: Automatic full peripheral ultrasonic testing of

seamless and welded ( except submerged arc welded) steel tubes for the detection of

longitudinla imperfections.

EN10246-8, Non-Destructive Testing of steel tubes - Part 8: Automatic ultrasonice testing of the weld

seam of electric welded tubes for the detection of longitudinal imperfections.

EN10246-9, Non-Destructive Testing of steel tubes - Part 9: Automatic ultrasonice testing of the weld

seam of submerged arc-welded tubes for the detection of longitudinal and/or

transverse imperfections.

EN10246-10, Non-Destructive Testing of steel tubes - Part 10: Radiagraphic testing of the weld

seam of atuomatic fusion arc-welded tubes for the detection of imperfections.

EN10246-14, Non-Destructive Testing of steel tubes - Part 14: Automatic ultrasonic testing of the

seamless and welded (except submerged arc welded) steel tubes for detection of laminar

imperfections

EN10246-15, Non-Destructive Testing of steel tubes - Part 15: Automatic ultrasonic testing of strip/plate

used in the manufacture of steel tubes for detection of laminar imperfections

EN10246-16, Non-Destructive Testing of steel tubes - Part 16: Automatic ultrasonic testing of the area

adjacent to the weld seam of welded steel tubes for the detection of laminar imperfections

EN10246-17, Non-Destructive Testing of steel tubes - Part 17: Automatic ultrasonic testing of tube ends

of seamless and welded steel tubes for the detection of laminar imperfections

EN10256, Non-Destructive Testing of steel tubes - Qualification and competence of level 1 and level 2

NDT personnel

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- sales

- Address

- Room706,Qiling Mansion, Yinzhou District, Ningbo,China 315100

- Product Category

- Steel Pipes

- No. of Total Employees

- 101-500

- Company introduction

-

Torich Interational Co.,Ltd is a professional manufacturer and exporter of steel pipes materials. It is an international marketing and sales company specialized in steel tubes, which holds the factories of Seamless Steel Tubes with Carbon and Alloy Steel Grade, Welded Precision Steel Tubes,DOM Steel Tubes, Seamless & Welded Stainless Steel Tubes with Nickel and Alloy Steel Grade.

Our factory was established since 1997, with the name of Haiyan Sanxin Steel Pipe Co., Ltd. The factories’ technicians are of great engineering experience in steel pipe industry for more than 20 years, which are in great command of production technology for Cold Drawing and Cold Rolling. So we have strong technician team and manufacturing capability.

- Main Product

Related Products

Stainless Steel Sheet

Hastelloy C-22 Filter Media

Stainless Steel Double Ring Press Joint SP-JOINT

CARBON STEEL, STAINLESS STEEL, DUPLEX PLATE

Intermediate Crimped Wire Mesh

China

China