Ceramsite sand cerabeads ceramic foundry sand

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Haixu abrasives

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- ceramic foundry sand, ceramic sand, ceramsite sand, cerabeads

- Category

- Abrasives

Apply a video call to the Supplier

Zhengzhou haixu abrasives co.,ltd

- Verified Certificate

-

9

| Product name | Ceramsite sand cerabeads ceramic foundry sand | Certification | - |

|---|---|---|---|

| Category | Abrasives | Ingredients | - |

| Keyword | ceramic foundry sand , ceramic sand , ceramsite sand , cerabeads | Unit Size | - |

| Brand name | Haixu abrasives | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 6914 |

Product Information

This new developed specific Foundry Sand is produced from the special selected high quality refractory raw material at very high temperature at 2,300 – 2,500℃. Our these ACFS sand has excellent solid cores with high strength and very low resin addition rates. The materials has excellent crystalline with formula is 5Al2O3-SiO2. Application: Shell moulds and cores for casting gray, Malleable and nodular cast iron, alloyed steel and carbon steel, non-ferrous metals, etc. |

The Main Advantage Stabe quality on the chemical composition Perfect grain round shape and various grain sizes High gas permeability High temperature resistance Good break down and fast curing and good release |

Chemical Composition

SiO2 | 5– 15% |

Al2O3 | 70–85% |

Fe2O3 | 5%min |

TiO2 | 5%min |

MgO | 0.5%min |

K2O | 0.5%min |

CaO | 0.5%min |

Physical Character

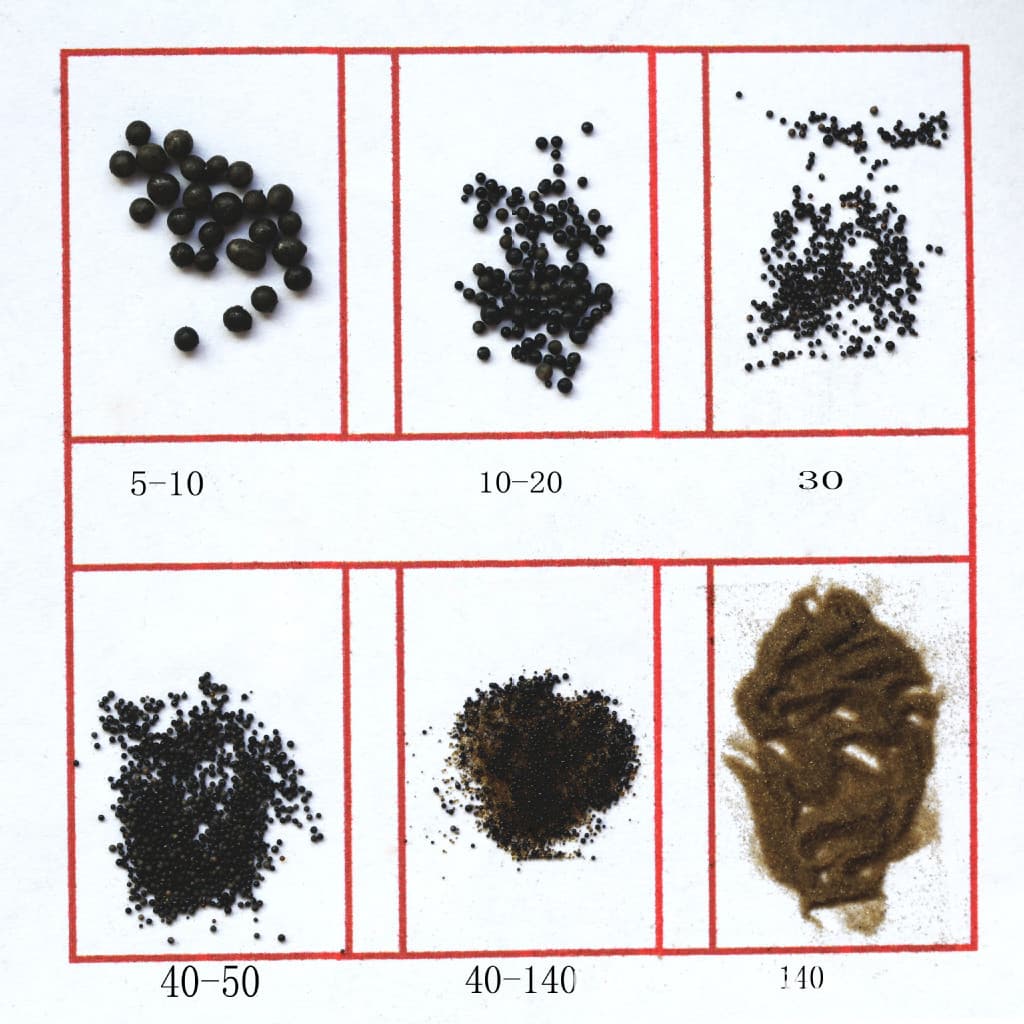

Grain shape | Perfect round ball shape |

Color | Brown-Black |

Angle index | 1 .1 max |

Size rang | 0.053-3.36mm |

Loose Bulk Density | 1.9 – 2.1 g/cm3 |

Refractoriness | 2050℃ |

Liner thermal expansion | (200℃ - 1000℃) 5×10-6/℃ |

Main Advantage

1 | Stabe quality on the chemical composition |

2 | Perfect grain round shape and various grain sizes |

3 | High gas permeability |

4 | High temperature resistance |

5 | Good break down and fast curing and good release |

6 | Perfectly round shape with higher fluidity improves fill-in efficiency while reducing the resin level |

7 | Smooth surface of spherical shape greatly improves collapsibility after pouring |

8 | Very low thermal expansion ensures fewer or no casting defects such as veining and deformation |

9 | Excellent thermal conductivity and heat absorption capacity close to that of Zircon |

10 | Superior refractory equivalent to Zircon and Chromites |

Applications

1 | Widely used in foundry technique like resin-bonded sand, sodium silicate sand, and clay- bonded sand for sand core and casting mould making |

2 | Replace chromite sand and widely used in sand core making like jacket core, oil duct core, tappet core of engine. |

3 | Replace chromite sand for steel casting facing sand and sub-layer of molding sand (backing sand). |

4 | Widely used as dry sand and sand box for EPC process and V method of casting processes. |

5 | Widely used as the main raw materials of advanced refractory products (Ladle drainage sand,gravity casting material, casting coating, etc.). |

6 | Widely used as cleaning sand for copper and aluminum alloy castings. |

PS:The main performance comparison of ceramic foundry sand,Chromite sand and Zircon Sand

| Ceramic Foundry Sand | Zircon Sand | Chromite Sand |

PH Value | 7.65 | 4.56 | 8.24 |

Bulk Density(g/cm) | 1.95-2.05 | 2.9-3.1 | 2.6-2.7 |

True Density(g/cm) | 3.4 | 4.4-4.71 | 3.9-4.8 |

Shape | spherical | Irregular | Irregular |

Binder into water(Waterglass +CO2 Hardness) | 3-4% | 7-8% | 7-8% |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Yingtao Feng

- Address

- A-801 Kaixuanmen Tongbai South Road

- Product Category

- Abrasives

- No. of Total Employees

- 51-100

- Company introduction

-

Zhengzhou Haixu Abrasives Co.,ltd ,founded in 1999, with more than 80 Staff including 10 professional and technical personnel, is specialized in production and sale of abrasives. Our main products are white fused aluminum oxide, brown fused aluminum oxide,black aluminum oxide and silicon carbide and other related products running under the certifications G B , I S O,F E P A and J I S . At present, our annual production capacity is about 30000tons and sales exceeded 100 millions. Our company owns science Management system and perfect quality control system with all kinds of testing equipment such as Omec, slap-sieve and microscope.

In order to serve our international customers better and make our abrasive products to global market widely, we established Henan Sicheng Co.,ltd in 2010,which is specialized in international business in abrasive field. Since its establishment, until now we have supplied our abrasives products to more than 200 customers from over 40 countries, and received a favorable report from customers both home and abroad

All staff from Haixu Abrasives hope to cooperate with you sincerely, and finally to get win-win situation.

- Main Markets

-

Indonesia

Indonesia

Malaysia

Malaysia

Saudi Arabia

Saudi Arabia

South Korea

South Korea

Viet Nam

Viet Nam

- Main Product

Related Products

98% Black Silicon Carbide SiC for Abrasive Products

Diamond Polishing Slurry

white fused alumina fine powder

Cast Stainless Steel Shot

sand paper (Automotive)

China

China