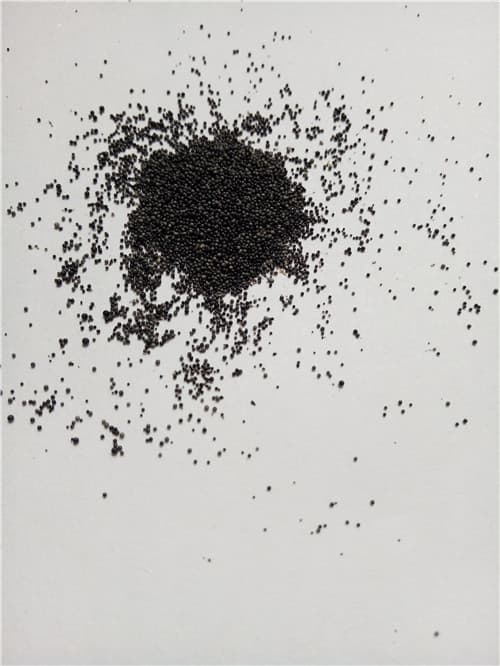

resin bonded sand precision casting sand 40-70mesh

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- kangqian

- Payment Terms

- MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- cast, casting sand, resin bonded sand, precision sand

- Category

- Cast & Forged , Refractory

Apply a video call to the Supplier

Henan Kangqian Import and Export Company Limited

- Verified Certificate

-

8

| Product name | resin bonded sand precision casting sand 40-70mesh | Certification | - |

|---|---|---|---|

| Category |

Cast & Forged

Refractory |

Ingredients | - |

| Keyword | cast , casting sand , resin bonded sand , precision sand | Unit Size | - |

| Brand name | kangqian | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 6914 |

Product Information

resin bonded sand precision casting sand 40-70mesh

Ceramsite specification

1. Introduction

Ceramsite, also called as NFS CERAMSITE-Nice Foundry Sand, is kind of man-made spherical shape ceramic particles featured by high refractoriness, low thermal expansion made by spraying melted from the fused bauxite. It provides a simple and efficient way in the foundry industry to improving the quality of the castings, reducing the production cost and avoiding environmental pollution so it is much better than silica sand. And it is also good substitution to Chromite sand and Zircon sand because of its lower price.At the present, Ceramsite is acknowledged in the worldwide as the newest and the best ideal sand for the foundries and has a very wide feasibility of applications for the future development.

2. Specification

Shape: Sphere

Angle Factor: <1.1

Bulk Density: 1.95-2.05 (g/cm3)

Refractoriness: >1790°C

Thermal expansion: 0.13% (10 minutes under 1000°C)

Main Chemical composition (typical value as following table):

Unit | Al2O3 | SiO2 | Fe2O3 | TiO2 | CaO | MgO | K2O | Na2O |

% | 75.36 | 17.72 | 2.16 | 3.23 | 0.43 | 0.35 | 0.33 | 0.08 |

3. CERAMSITE advantages

Solid sphere: The shape of Ceramsite is spherical with smooth surface and less surface area and offering a very good flowability and filling ability. To compare with other sands else, less binder is used at the same mold strength and higher venting ability. It also offers the excellent collapsibility.

Lower thermal expansion rate: It makes the dimensions of castings better, less crack and defect and higher output.

Lower breakage rate: Ceramsite has a higher density and a very lower breakage rate at the reclaimation. It makes a better reclamations rate to reduce the waste sand and the pollution.

High refractoriness: The major chemistry is Al2O3 and SiO2, so mostly mullite and corundum phase in the Ceramsite which will make sure the high refractoriness and thermal stablity. And PH Value appears neutral. It is suitable for all kinds of metal and alloy castings.

4. Application Area

1.Foundry

2.Surface shot peening

3.Starting Mix for steel Ladle

4.Refractory Costing

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Andy He

- Address

- No.202,qinling Road

- Product Category

- Other Aluminum

- Year Established

- 2015

- Company introduction

-

Henan Kangqian Import and Export Company Limited is a professional manufacturer of Ceramsite。We make great effort to become a quality-oriented and trustworthy enterprise which could consistently provide our customers with high-quality, cost-effective, energy-saving and environmental friendly quality products.

The Ceramsite has lots of advantages such as high refractoriness, high recovery rate, low thermal expansion coefficient, good air permeability, resistance to acid corrosion, is widely welcomed by domestic and foreign foundries, More than 10,000 tons supply quantity of per year could be your stable and reliable supplier.

Multi-applications Ceramsite are available,such as Lost foam casting(expendable pattern casting or EPC) used ceramsite,Precoated sand making used ceramsite,sand blasting used ceramsite,resin sand used ceramsite,precision casting used ceramsite powder,painting used ceramsite powder and steel Ladle drainage agent used ceramsite,Various models from 10mesh to 270mesh are available and special needs are acceptable.

Our products are widely exported to Germany, UK, USA, South Korea, Japan and other countries and well-known by casting enterprises which used in various fields.

- Main Product

Related Products

Ceramic Foam Filter CFF-S

TUBE SHEET

wind turbine tower flange

Ceramic fiber blanket

Corundum-Mullite Crucibles For Melting Steel

China

China