Continuous waste plastic pyrolysis plant

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- DY

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- pyrolysis plant, plastic pyrolysis plant, waste plastic pyrolysis plant, continuous waste plastic pyrolysis plant

- Category

- Plastic & Rubber Machinery Parts

Apply a video call to the Supplier

DoingGroup

- Verified Certificate

-

8

| Product name | Continuous waste plastic pyrolysis plant | Certification | - |

|---|---|---|---|

| Category | Plastic & Rubber Machinery Parts | Ingredients | - |

| Keyword | pyrolysis plant , plastic pyrolysis plant , waste plastic pyrolysis plant , continuous waste plastic pyrolysis plant | Unit Size | - |

| Brand name | DY | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Product introduction of continuous waste plastic pyrolysis plant

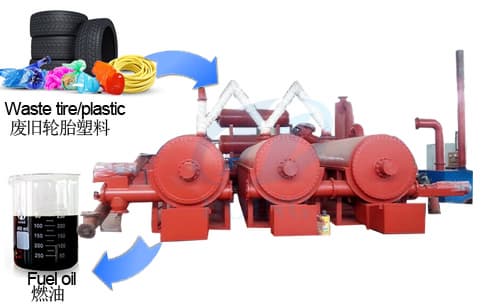

Continuous waste plastic pyrolysis plant

We,Henan Doing Mechanical Equipment Co.,Ltd is a leading manufacturer specialized in waste tire /plastic/rubber pyrolysis plant has developed continuous waste plastic pyrolysis plant.

Our continuous waste plastic pyrolysis plant can continuously process plastic into crude oil and carbon blacks without stop. All the continuous waste plastic pyrolysis plant is controlled by PLC(programmable logic controller), so it is very easy to operate it and our customers can save much cost of time and labor.

Feedstock & product of continuous waste plastic pyrolysis plant

Feedstock & product of continuous waste plastic pyrolysis plant

For our continuous waste plastic pyrolysis plant,the applicable raw materials can be polythene,polypropylene,polystyrene,ABS...

The final products from plastics continuous pyrolysis process will be fuel oil and carbon black.

Feedstock & product of continuous waste plastic pyrolysis plant

Working process of continuous waste plastic pyrolysis plant

Working process of continuous waste plastic pyrolysis plant

1.All available plastic can be shredded by plastics crusher, and then feed plastic granules directly into plastic continuous pyrolysis plant through the feeding door.

2.Our feeding door is with screw inside, so it can help you easily convey the plastic granules into our reactor No 1, then all the plastic can be decomposed under the high temperature through reactor No 1 to reactor No 2,then to reactor No 3...Until all the plastic fully pyrolysed, then all the carbon black powder will be discharged automatically to the carbon black tank.

3. All the available oil gas will be cooled by circulation water and the extra pyrolysis gas will be recycled through pipes into the burners for heating again. In our continuous waste plastic pyrolysis plant,the water circulation system and extra pyrolysis gas recycling system will help you save much fuel and water resource,in this way, our plastic continuous pyrolysis plant can minimize your cost and maximize your profits.

Main features of continuous waste plastic pyrolysis plant

1: Fully automatic with low labour cost

Our conitnuous waste plastics pyrolysis plant is controlled by PLC system with automatic feeding and discharge system, which only need 1-2 worker for operating the PLC or computer is ok.

2:Fully pyrolysis for high oil output

Our continuous waste plastics pyrolysis plant adapts to multiple reactor design which can make fully pyrolysis of waste plastics, thus to get high oil output.

3:Big capacity

Also due to continuous feeding and discharge system, and unique multiple reactor design, our fully automatic continuous waste plastics pyrolysis plant can process at least 10 tons waste plastics per day, up to 100T/D.

4: Internal rotating for continuous operation

For external rotating system, you have to change the sealing material every three days, thus cannot achieve he real sense of continuous process. But our continuous waste plastics pyrolysis reactor adapts internal rotating method, which no need to worry about the sealing of the external rotating system.

Continuous working save time and energy

5:Long working life

During the continuous pyrolysis process, reactor is heated by indirect hot air heating, which will not damage reactor so much, thus to keep long usage life of the reactors.

Technical parameters of continuous waste plastic pyrolysis plant

No. Item Specifications

1 Model DY-C-10 DY-C-20 DY-C-30 DY-C-50 DY-C-60 DY-C-80 DY-C-100

2 Cpacity 10T/D 20T/D 30T/D 50T/D 60T/D 80T/D 100T/D

3 Power 35Kw 50Kw 65Kw 80Kw 90Kw 105Kw 120Kw

4 Working type Continuous

5 Reactor deisgn Mutiple reactors (The quantity and size depends on the raw material condition)

6 Rotating Internal rotating

7 Cooling system Recycled waster cooling

8 Reactor material Q245R/Q345R boiler plate

9 Heating method Indireact hot air heating

10 Heating fuel Fuel oil/gas

11 Feedstock Waste tire/plastic/rubber

12 Output Fuel oil, carbon black

Solution of fully automatic continuous waste plastic pyrolysis plant

If you’re facing waste plastics pollution or disposal problems, and be badly in need of a processing system, please feel free to contact us. We DOING Company are always ready to provide you the best solution.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

+86 15893800169

Skype: bonniezhao2

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Bonnie

- Address

- No.138 Yingxie Road,Jinshui District,Zhengzhou, Henan Province, China

- Product Category

- Crude Oil,Other Metal & Metallurgy Machinery,Waste Management

- Year Established

- 1976

- No. of Total Employees

- 101-500

- Company introduction

-

Henan Doing Mechanical Equipment Co., Ltd is a comprehensive enterprise related to manufacture, marketing, installation and after sale service etc.

The company is committed to developing and manufacturing of all kinds of large scale and small acale equipment. It won leading position and good reputation with its high quality products and professional service.

The main products: scrap cable wire recycling machine. PCB (Printed Circuit Board ) recycling machine. Aluminum and plastic composition recycling machine. Home electric applaince recycling machine, etc.

waste tire and plastic recycling machine with relavent equipements, like tire cutter, carbon black briquette machine and carbon black grinding mill etc;

waste engine oil, waste tire and plastic oil refinery machine and relavent euipments, like oil filter etc;

Our machinery have been sold to Italy, Romania, Macedonia, Albania, Estonia, Rusia, Egypt, Ethopia, Nigeria, Congo, Lebanon, Jordan, Iran, Pakistan, Kazakhstan, India, Tailand, Malaysia, Mexico, Panama, Guatemala, Aruba, Jamaica, Ecuador, Haiti etc.

Company has won good reputation with its advanced production technology, professional installation and after-sales service.

Welcome your visit!

- Main Product

China

China