Waste plastic to fuel oil pyrolysis plant

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- DOING

- Payment Terms

- D/A,D/P,L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Plastic Products

Apply a video call to the Supplier

DoingGroup

- Verified Certificate

-

8

| Product name | Waste plastic to fuel oil pyrolysis plant | Certification | - |

|---|---|---|---|

| Category | Plastic Products | Ingredients | - |

| Keyword | plastic to oil , pyrolysis plant , plastic to fuel oil , plastic pyrolsyis plant | Unit Size | - |

| Brand name | DOING | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Waste plastic to fuel oil pyrolysis plant

The pyrolysis of plastics waste is a new green technology to recycle plastic and we Doing group have applied this technology in our plant. By using the plastic to fuel oil pyrolysis plant, finally you can get oil from the plastic waste, and you can also get the carbon black and combustible gas, all of which have a wide range of applications.www(dot)wastetireoil(dot)com

According to the demands of different customers, we provide three types of plastic to fuel oil pyrolysis plants for customers, including batch operating plant, semi-automatic operating plant and auto continuously operating plant. Each set of plant is manufactured with advanced technologies and has the features of high efficiency and low cost. The following are some technologies applied in the plant:

1. The first in the world to have created the new heating structure that combines the advantages of burning the reactor directly and heating the main reactor by hot air.

2. The technology of avoiding the reactor of being burnt through by reforming the furnace, which will lengthen the life span of the main reactor for 5 to 8 years and save quite amount of money for customers to maintain and update the plant.www(dot)wastetireoil(dot)com

3. The technology of improving the oil yield by another 5% compared with the traditional plant.

4. The technology of guaranteeing 100% safety in the whole working process.

5. The technology of ensuring the released gas reach the European pollution control standards.

Working process of waste plastic to fuel oil pyrolysis plant

Waste plastic to fuel ol pyrolysis plant working process

Put raw material into reactor by full-automatic feeding machine. The reactor is supposed to be left 1/3 space for rotating more smoothly. Then make sure the door of feeding machine is closed.

Reactor will be gently heated by burning the fuel material (coal, wood, natural gas, LPG or tire oil generated from last batch). The oil gas will be released when the temperature reached 100℃ (250-280℃ is the top output rate interval). Heavy oil gas separated by manifold is supposed to be liquefied and drop down into the heavy oil tank. The lighter gas will rise up to the oil condensers, be liquefied into oil and stored in the oil tank. The incondensable gas through dusulphuration and dedusting by hydroseal will be led to the furnace for recycling.

After all the above work has been done, cool down the reactor. Then the carbon black will be discharged automatically.

There possibly will be a little exhaust gas left, and you should not expel it until it has reached the emission standard.www(dot)wastetireoil(dot)com

Before starting next batch, make sure all the work has been done.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,T/T | Shipping time | Negotiable |

- President

- Bonnie

- Address

- No.138 Yingxie Road,Jinshui District,Zhengzhou, Henan Province, China

- Product Category

- Crude Oil,Other Metal & Metallurgy Machinery,Waste Management

- Year Established

- 1976

- No. of Total Employees

- 101-500

- Company introduction

-

Henan Doing Mechanical Equipment Co., Ltd is a comprehensive enterprise related to manufacture, marketing, installation and after sale service etc.

The company is committed to developing and manufacturing of all kinds of large scale and small acale equipment. It won leading position and good reputation with its high quality products and professional service.

The main products: scrap cable wire recycling machine. PCB (Printed Circuit Board ) recycling machine. Aluminum and plastic composition recycling machine. Home electric applaince recycling machine, etc.

waste tire and plastic recycling machine with relavent equipements, like tire cutter, carbon black briquette machine and carbon black grinding mill etc;

waste engine oil, waste tire and plastic oil refinery machine and relavent euipments, like oil filter etc;

Our machinery have been sold to Italy, Romania, Macedonia, Albania, Estonia, Rusia, Egypt, Ethopia, Nigeria, Congo, Lebanon, Jordan, Iran, Pakistan, Kazakhstan, India, Tailand, Malaysia, Mexico, Panama, Guatemala, Aruba, Jamaica, Ecuador, Haiti etc.

Company has won good reputation with its advanced production technology, professional installation and after-sales service.

Welcome your visit!

- Main Product

Related Products

_Pipe_2.jpg)

COD (Corrugated Optic Duct) Pipe

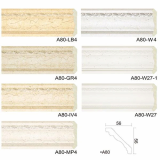

HI-WOOD Picture Frame, Interior Moulding, PS moulding

RC Level Rod

Cosmetic packaging: L series

Cosmetic packaging: F series

China

China