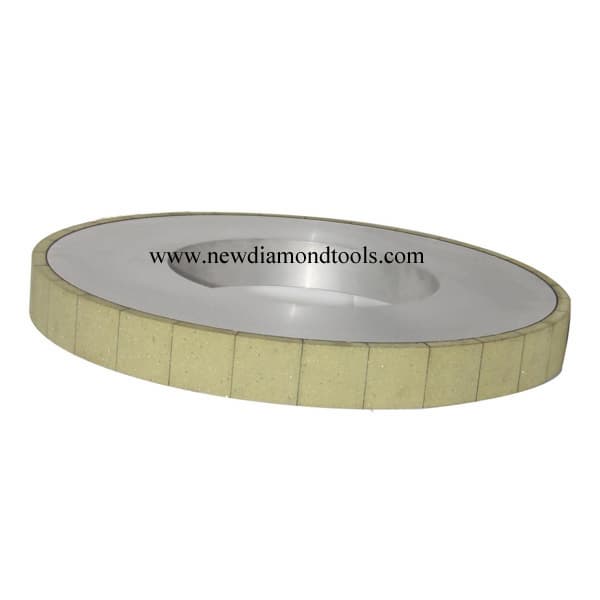

Vitrified Diamond Grinding Wheel for rough Grinding PDC

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- xinzuan

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery Parts

Apply a video call to the Supplier

Xinxiang New Zuan Diamond Tools Co., Ltd

- Verified Certificate

-

7

| Product name | Vitrified Diamond Grinding Wheel for rough Grinding PDC | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | diamond grinding wheel , vitrified diamond grinding wheel , grinding wheel for pdc | Unit Size | - |

| Brand name | xinzuan | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

PDC (polycrystalline diamond compact) is a composite material sintered by diamond powder and carbide substrate under high temperature and high pressure. The abrasion loss reach 13-40 million, that are extremely difficult to process.

Vitrified bond diamond abrasive tools have the common features of vitrified bond agent and diamond. Compared with ordinary abrasive tools, it has strong grinding ability, low grinding temperature, high wear, good shape maintain, high precision machining parts, good self-sharpening for abrasive itself, interval of a long time for dressing, easy to dressing, not easy to jam when grinding, not easy to burn the workpiece, and can use a variety of coolant for cooling.

Vitrified diamond grinding wheel in the processing of PDC has the following advantages, compared to resin diamond grinding wheel.

① Vitrified diamond grinding wheel is 3 times the grinding efficiency of the resin diamond grinding wheel.

② Vitrified diamond grinding wheel do not need to be dressed no longer, in addition to the in the entire grinding process, in addition to the grinding wheel surface sharpen first. Resin diamond grinding wheel must be trimmed 7 to 12 times, or do not grind the workpiece.

③ The shape of PDC that is ground by vitrified diamond grinding wheel is very different. The side of PDC project into isosceles trapezoidal that is grind by resin bond diamond grinding wheel.

The base there has diamond layer is much larger than the other end. The side of PDC which is ground by vitrified diamond grinding wheel project into rectangular, the two surface size is the same. The dressing time will reduce when grinding, and the workpiece processing accuracy is high, and the gloss is high. When PDC will be ground by resin bond diamond grinding wheel, there will cutter back-off. This is mainly because resin bond diamond grinding wheel has certain flexible and will concessions when grinding. But the vitrified diamond grinding has large overall elastic modulus, good rigidity, heat resistance, will not cause cutter back-off phenomenon.

④ The workpiece finish is better than that of resin diamond grinding wheel process. Because the resin diamond grinding wheel is not heat resistance, it is easy soft at 200 ℃, resulting in a great brittle, causing the diamond grinding wheel chip. So the grinding wheel is often added more copper powder for cooling, but the extension of copper is large, easy to stick to the PDC around, making the product processing is not bright. The products which are processed by vitrified diamond grinding wheel can reach the mirror gloss, coarse grinding and fine grinding as one process will be completed.

⑤Large feed. If resin diamond grinding wheel use large feed, the parts will not be ground, or the grinding wheel collapse.

In summary, when vitrified diamond grinding wheel grinding PDC product, it has high grinding efficiency, less dressing time, high accuracy of workpiece processing size, good finish, vitrified diamond grinding wheel is the ideal of grinding PDC.

The vitrified diamond grinding wheel we produced for the PDC in the process of processing composite product has characteristics of high grinding efficiency, high processing accuracy.

Rough Grinding PDC Cylindrical Vitrified Diamond Grinding Wheel for Diamond Composite Product Rough Machining

|

Type |

D(mm) |

T(mm) |

H(mm) |

X(mm) |

|

1A1 |

200 |

50 |

75 |

10 |

|

1A1 |

250 |

50 |

75 |

10 |

|

1A1 |

300 |

50 |

127 |

10 |

|

1A1 |

350 |

50 |

127 |

10 |

|

1A1 |

400 |

50 |

203 |

10 |

|

1A1 |

450 |

50 |

228.6 |

10 |

|

1A1 |

500 |

50 |

305 |

10 |

|

According to customer's requirement | ||||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Owen Wang

- Address

- 18# Jingu Orential Piazza, Jinsui Road, Xinxiang, Henan 453000, China

- Product Category

- Abrasive Tools

- Year Established

- 2015

- Company introduction

-

Xinxiang New Zuan Diamond Tools Co., Ltd is a professional diamond tools and CBN tools supplier, the main production diamond saw blade, diamond polishing pad, diamond grinding wheel, diamond drill, diamond brush, CBN products, products are widely used in stone industry, ceramics industry, glass industry, magnetic materials and automotive industryResin bond diamond/CBN grinding wheelMetal bond diamond/CBN grinding wheelVitrified bond diamond/CBN grinding wheelDiamond /CBN honing stoneDiamond grinding wheel for optical glassDiamond grinding wheel for silicon waferDiamond grinding wheel for crystal glassDiamond grinding wheel for fiber ceramicDiamond grinding wheel for PCD,PCBN toolsDiamond grinding wheel for hard carbideDiamond grinding wheel for sapphireDiamond grinding wheel nature diamondDiamond polishing pad for stone,concrete,terrazzoDiamond /CBN abrasive beltDiamond saw bladeDiamond core drill bitDiamond abrasive brush

- Main Product

Related Products

Vagcom 17.1.3 ATMEGA162 VCDS 17.1.3 China crack VAG 17.13 Fo

RC Level Rod

Electric ULV Sprayer ATOMER 2

MECHANICAL PACKING, GLAND PACKING, YARN ROPE PACKING

yacht fittings

China

China