Diffuser Sheet for UGR Solution

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- j.kplas

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- diffuser sheet for back-lit led luminaire, diffuser sheet, j.k acrylic diffuser, diffuser sheet for ugr solution

- Category

- Other Building Lighting

Apply a video call to the Supplier

J.K optical Plastic Co., Ltd.

- Verified Certificate

-

6

| Product name | Diffuser Sheet for UGR Solution | Certification | - |

|---|---|---|---|

| Category | Other Building Lighting | Ingredients | - |

| Keyword | diffuser sheet for back-lit led luminaire , diffuser sheet , j.k acrylic diffuser , diffuser sheet for ugr solution | Unit Size | - |

| Brand name | j.kplas | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

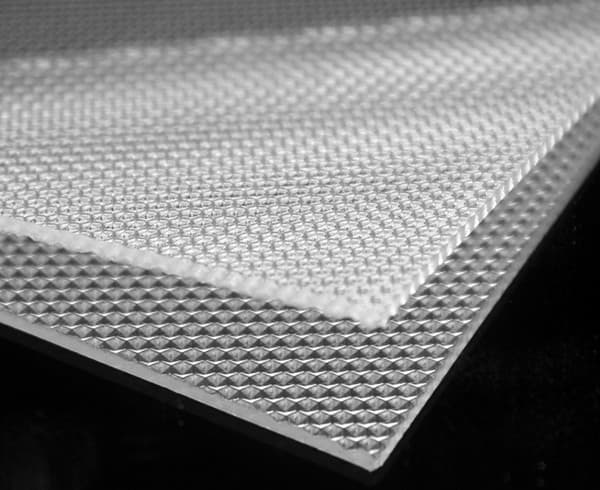

1. Prism Cone UGR diffuser with Concave hexagon,cone bottom,takes on homogeneous look due to unidirectional structure;

2. Scientific designed structure,well defined lamp direction with average beam angle 85 degree,assist to improve the light efficiency and reasonable glare suppression;

3. Homogeneous glare reduction in all C-levels,excellent for workstations required lighting application UGR<19,for example LED Panel light;

4. On equal conditions, the light transmittance is obvious higher than traditional matte or orange peel texture diffusion sheet, at the same time effectively suppress the glare value.

Product Details

Dimension(L*W*T) | |||

Length | width | Thickness |

|

1200mm | 1200mm | 1.5mm |

|

Pattern | Concave hexagon,cone bottom |

| |

Note: according to customer demand for different mold, build the required size | |||

Temperature range:

A.storage temperature:25℃±10。

B.Long term use environment temperature:0~80℃

C.relative air humidity:45%~75%。

|

Item | Test Method | Unit | PMMA |

transmission rate | Transmissometer | % | 92% |

Haze | Transmissometer | % | 80% |

water adsorption | ASTM D570-98 | % | 0.3 |

distortion temperature | ASTM D648-07 | ℃ | 88 |

vicat softening temperature | ASTM D1525-09 | ℃ | 104 |

linear expansivity | ASTMD696 | cm/cm/℃*10-5 | 7.6 |

Thermal conductivity | ASTMD177 | Cal/cm*sec℃*10-4 | 4.5 |

HRR | ASTM D785-08 | - | 123 |

flammability | UL 94-1996 |

| flammability |

UGR | UGR |

| ≤19 |

Product Ingredient:PMMA, PE protection film

Scientific designed structure,well defined lamp direction with average beam angle 90 degree,assist to improve the light efficiency and reasonable glare suppression;

excellent for workstations required lighting application UGR<19,for example LED Panel light;

Attention:

In conjunction with diffusion film and light guide plate,Prism Cone diffuser positioned in outer layer with the texture facing away from the led or lamp;diffusion film located in the middle layer with the microstructure facing away from the led or lamp also; the light guide plate placed on the bottom layer with the texture side placed contrary to prisma cone and diffusion film.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- manager

- Address

- LED Trading Center, Shuncheng Industry Zone, Guzhen Town Zhongshan, Guangdong

- Product Category

- Other Building Lighting

- Year Established

- 2012

- No. of Total Employees

- 101-500

- Company introduction

-

<p>J.K optical Plastic Co., Ltd is a group with two division factory which specialize in optical plastic sheet manufacturing, has been serving the lighting industry for almost 10 years, products included: UGR diffuser(ugr < 19), Acrylic textured/pattern sheet, Acrylic diffuser, thermoforming plastic sheet and PC reflective film, it’s widely used in Fluorescent light fixtures, Led panel light, Ceiling light and so on. So far we have introduced five advanced Co-extrusion equipments, and raw material we only use"Mitsubishi" from Japan and "LG" from Korea, The key manufacturing procedures of extrusion, calendaring, cooling, and masking film are all completely in dust-free condition. The production lines are fully automatic and controlled by computer, and now is one of the leading companies in the china acrylic industry, which monthly process capability reach to 800 tons, and share a large market in china. As a commitment to our customers, J.K continues to re-invest heavily in research and development along with the very latest technology in our plants, for a continued stream of new products, quality and cost control. This enables J.K to assist our customers in meeting the everyday challenges in an ever changing global marketplace.

- Main Markets

-

South Korea

South Korea

- Main Product

Related Products

_Black_from_Korea__2.jpg)

Twisted 2-strands fish tape 15M(49.2ft) Black from Korea.

metal halide lamp

LED LAMP

Softbox-SQUARE

QSD Lamp l SECURITY LIGHTING

China

China