Bearing Application

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Bearings

Apply a video call to the Supplier

Higen Motor Co., Ltd.

- Verified Certificate

-

15

| Product name | Bearing Application | Certification | - |

|---|---|---|---|

| Category | Other Bearings | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Bearing application

Ready Inspection and Easy Maintenance through Unique Bearing Construction

The ball and roller bearings can be greased while the motor is running. Waste grease is collected in a grease trap mounted on each end bracket. The used grease is removed with a single stroke of the discharge handle, simplifying inspection and maintenance. In frame sizes 500 or above, roller bearings at each end absorb radial load, and ball bearings at the drive end absorb thrust load. This assures stability and longer life.

Sleeve bearings employ efficient sealing between shaft and bearing to prevent lubricants from leaking either into the motor housing or outside the housing. The sleeve bearings are split into two halves. Removing the upper half exposes the bearing interior. Bracket removal is not required for inspection or maintenance.

|

Type

|

BD,BS-O,ME

|

HE

|

||

|

Pole

|

4-Pole

or more |

4-Pole

|

6-Pole

|

8-Pole

|

|

Frame

|

||||

|

400

|

Ball or roller bearings

(Grease lubrication) |

|||

|

450

|

||||

|

500

|

||||

|

Bearing application of motors in 4-pole or more is listed above.

|

|

Ball

or Roller Bearing |

Frame

450 or below |

|

|

Frame

500 or above |

||

|

Sleeve

Bearing |

||

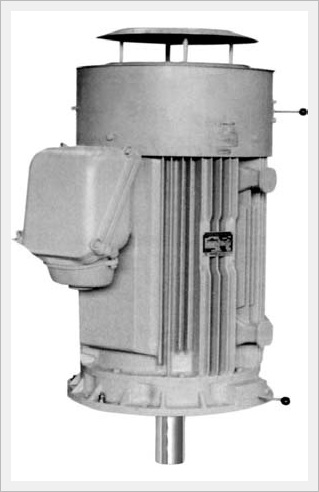

| HIGEN Motor Totally Enclosed Fan Cooled Vertical motors are designed to IEC dimension. As the apparatus is built with the main body that is totally enclosed, and cooled by a cooling fan on the opposite drive end, it allows direct installation of a counter apparatus on flange part by using it as a linkage axis bracket. It ensures a full performance of its advantage as motors for Machine tools, Pumps, Centrifuges etc. Often committed in dusty and humid environments. |

Type FEV-0 55kW 4p |

RATINGS AND SPECIFICATIONS

- Standard Out put Ranges : See Table 1

- Types and Starting Torgue.

TYPE FEVK - Squirrvel-Cage, Starting 100% or above full-load torgue.

TYPE FEVF - Squirrvel-Cage, Starting 150% or above full-load torgue. - Time Rating : continuous

- Rated Vottage : 6000V 50Hz, 6600V 60Hz

- Insutation : Class F

- Allowable Temperature rise : 100â (by resistance method)

- Bearings : Regreasable ball or roller bearings

- NO.of Motor Leads : 3

- Connection to Load : Direct drive.

- Finish in munsell Notation : 5PB 8 / 2.5(Blue)

<Table1> Standard Output Ranges

| 1. Motors cannot carry thust losd from driven machine. 2. Motors other than thse listed above are available. |

<Table2> Characteristics

|

Voltage

|

Pole

|

Output

(kw) |

Frame

FEV |

Full-load

Current (A) |

Full-load

Pole Speed (rpm) |

FEVRotor

GD2 (kg·m2) |

||

|

50 (Hz)

|

60 (Hz)

|

50 (Hz)

|

60 (Hz)

|

|||||

|

High

Voltage |

4

|

90

|

280 MBS

|

22

|

19.5

|

1475

|

1775

|

6

|

|

110

|

280 MBS

|

26.5

|

24

|

1475

|

1775

|

7.2

|

||

|

132

|

315 MBG

|

31.5

|

28.5

|

1480

|

1780

|

11.2

|

||

|

160

|

315 MBG

|

37.5

|

34

|

1480

|

1780

|

13.2

|

||

|

200

|

355 MBG

|

46.5

|

42

|

1480

|

1780

|

17.2

|

||

|

250

|

355 MBG

|

58

|

52

|

1480

|

1780

|

21.2

|

||

|

315

|

355 MBG

|

72.5

|

65

|

1480

|

1780

|

33.2

|

||

|

6

|

75

|

280 MBS

|

20

|

18

|

980

|

1180

|

6.4

|

|

|

90

|

280 MBS

|

23.5

|

21

|

980

|

1180

|

7.6

|

||

|

110

|

315 MBG

|

28.5

|

25.5

|

980

|

1180

|

12.0

|

||

|

132

|

315 MBG

|

34

|

30

|

980

|

1180

|

14

|

||

|

160

|

355 MBG

|

41

|

36.5

|

985

|

1185

|

18

|

||

|

200

|

355 MBG

|

51

|

45

|

985

|

1185

|

23.2

|

||

|

250

|

355 MBG

|

62.5

|

55.5

|

985

|

1185

|

35.2

|

||

|

8

|

37

|

280 MBS

|

11.5

|

10

|

735

|

885

|

5.6

|

|

|

45

|

280 MBS

|

13.5

|

12

|

735

|

885

|

6.8

|

||

|

55

|

280 MBS

|

16.5

|

14.5

|

735

|

885

|

7.2

|

||

|

75

|

280 MBS

|

21.5

|

19

|

735

|

885

|

9.6

|

||

|

90

|

315 MBG

|

25.5

|

22.5

|

735

|

885

|

14

|

||

|

110

|

315 MBG

|

30.5

|

26.5

|

735

|

885

|

19.2

|

||

|

132

|

355 MBG

|

36

|

31.5

|

735

|

885

|

21.2

|

||

|

160

|

355 MBG

|

43

|

38

|

735

|

885

|

27.2

|

||

TERMINAL BOXES AND POWER LEAD SIZE

Shown in the table 3 are standard application of terminal boxes to motor output and applicable lead size to the terminal boxes.

<Table3> Terminal Boxes and Power Lead Sizes

|

Motor Ratings

|

Sectional Area

of Power Lead Conductor (mm2) |

Terminal Boxes

Motor Ratings (Made of Steel Sheet) |

||||

|

Voltage

(V) |

Output

(kw) |

Type

|

Power Lead

Entrance |

Dwg

No. |

||

|

High

Voltage |

3000

|

37 to132

160, 200 250 315 |

14 (Three-core)

22 (Three-core) 30 (Three-core) 50 (Three-core) |

KU-

300F |

An entrance

cover with 7mm dia hole is mounted |

1

|

CONSTRUCTION OF TERMINAL BOXES

<Drawing1>

DIMENSIONS in mm

Two types of the bearings are used for a motor.

Single-row cylindrical roller bearing are employed at drive end. Single-row deep-groove bearings are employed at opposite drive end. Motor is equipped with a short shaft extension for a direct-connected drive as standard.

|

Frame. FEV-

|

Flange

No. |

LA

|

LB

|

LC

|

LE

|

LG

|

DC

|

DD

|

KL

|

LL

|

LR

|

L

|

LZ

|

|

280 MBG

|

FE 600

|

600

|

550 js6

|

660

|

6

|

25

|

725

|

640

|

560

|

1170

|

170

|

1340

|

24

|

|

315 MBG

|

FE 600

|

600

|

550 js6

|

660

|

6

|

25

|

780

|

690

|

590

|

1270

|

170

|

1440

|

24

|

|

355 MBG

|

-

|

740

|

680 h7

|

800

|

5

|

25

|

860

|

750

|

630

|

1510

|

170

|

1680

|

24

|

|

Frame. FEV-

|

Flange

No. |

Shaft Extensin

|

Bearing No.

|

Approx.

Weight kg |

||||||||||

|

Q

|

QK

|

QR

|

S m6

|

T

|

U

|

W

|

PC

|

XE

|

XL

|

Drive

End |

Opp

Drive End |

|||

|

280 MBG

|

FE 600

|

170

|

140

|

1.2

|

85

|

14

|

9

|

22

|

50

|

M 12

|

20

|

NU 318

|

6318 C3

|

930

|

|

315 MBG

|

FE 600

|

170

|

140

|

1.2

|

95

|

14

|

9

|

25

|

63

|

M 16

|

27

|

NU 320

|

6320 C3

|

1190

|

|

355 MBG

|

-

|

170

|

140

|

1.2

|

95

|

14

|

9

|

25

|

63

|

M 16

|

27

|

NU 320

|

6320 C3

|

1800

|

| 1. Dimensions of the shaft extension key and keyway are based on KS (Korean Standard) B 1311 "Sunk keys and Their Corresponding Keyways."Shaft extension key is furnished 2. Tolerances on dimension LB of flange diameter and S of shaft extension diameter are based on KS B 0401 "Limits and Fits for Engineering." 3. Approximate motor weights are of maximum motors. 4. Terminal box can be turned to one of four positions, 90 degrees apart to provide easy entrance of the power leads. |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jae-hak Kim

- Address

- 2F KOAMI Bldg, 13-6 Yeouido-dong, Youngdeungpo-gu, Seoul

- Product Category

- Other Vehicle Accessories

- Company introduction

-

The legacy of HIGEN MOTOR as one of the big 3 motor manufacturers in Korea dates back to 1963 when Goldstar, the pioneer of Korean electronic industry, now renamed as LG, started motor production for import substitution.

In 2008, HIGEN MOTOR was spun off as an independent corporation specializing in motors and energy transfer solutions such as induction motors, servo drives and servo motors, inverter motors, permanent magnet motors, spindle motors, and related products of industrial grade with power rating of 0.4 kW to 1,500kW.

In the era of low carbon green growth, HIGEN MOTOR also has been actively participating in seeking environment friendly power solutions with developments of transverse flux motors, high-precision motion control servo systems, inverter built-in motors and electric vehicle motors.

We are fully dedicated to the vision of "Challenge to the World, Challenge to the Future" with our role as an energy efficient solution provider and invite our valuable customers to navigate with us to Our Future and World of HIGEN Dream.

- Main Product

South Korea

South Korea