Silicon Rubber Molding

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Plastic Product Making Machinery

Apply a video call to the Supplier

RPM Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | Silicon Rubber Molding | Certification | - |

|---|---|---|---|

| Category | Plastic Product Making Machinery | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

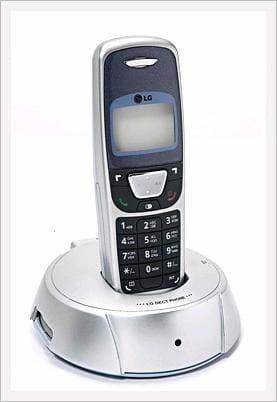

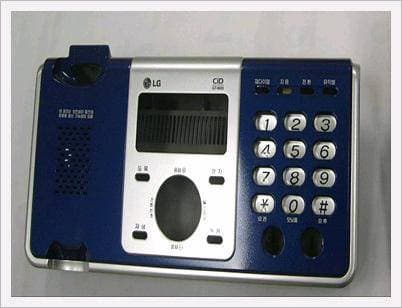

RPM utilizes Silicone Rubber Molding to offer prototypes and limited production runs to create parts with production-like aesthetics and material properties.

Silicone Rubber Molding is the process to create low-volume production parts from a polyurethane material via a silicone rubber tool.

The key advantage of this process is being able to obtain higher quantities of prototypes at relatively low cost and time.

Materials

ABS, PC, PP, PMMA, Rubber like polyurethane resin

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jae-pil, Lee

- Address

- #206, 1-na, Sihwa Industrial Complex, 1234-5 Jeongwang-dong, Siheung-si, Gyeonggi-do

- Product Category

- Other Design Services

- No. of Total Employees

- 1-50

- Company introduction

-

Established in 1994 as the first rapid prototype manufacturer in the territory, RPM was registered as an associate of Hyundai Motors. Then, the company established the technology research institute and acquired ISO 9001 and 14001 certificates. The company is also specialized in rapid prototype manufacturing business as moving to Siheung, Gyeonggi-do in 2007.

RPM do the best for manufacturing products, based on the accumulated expertise and experience in prototype and rapid Injection molding using 3D data. The company also saves the time and cost required to develop products by participating in prototyping, tooling and moulding among the entire process from designing and developing to completing mass production.

Competent engineers and the-state-of-the-art equipments are ready to promptly corresponding to customers' requirements on various products and a complete production system is established from one single prototype up to quantity of production in a short time.

- Main Markets

-

U.S.A

U.S.A

- Main Product

Related Products

PVC decorative film

RUBBER GRIP MOLD

Medical Silicone Catheter Tube Extruder Machine Line

PLASTIC PEN MOLD IN STOCK (BRAND NEW)

Medical dental saliva ejector tube making machine