Breaker - SQ Line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Apply a video call to the Supplier

Soosan Heavy Industries Co Ltd

- Verified Certificate

-

16

| Product name | Breaker - SQ Line | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Breaker - SQ Line

The SQ breakers are the latest design from Soosan. It is the result of more than 2 decades of experience since our foundation in 1984.

Through the active communication and monitoring of a large group of valuable customers from around the world we have gained working experience from the quarry, mining and construction industries.

The SQ series is a partically innovated hydraulic breaker whilst maintaining the superiority of the percussion mechanism and easy maintenance of the existing SB series.

- Medium Range

- For excavators from - 15 ton ~ 25 ton - Heavy-duty Range

- For excavators from - 21 ton ~ 100 ton

Applications

- Primary and secondary breaking in quarry

- Site preparation, foundation works

- Road construction

- Demolition works, heavily reinforced concrete

- Trenching

- Tunneling

- Bench leveling

- General construction works

Features & Advantages

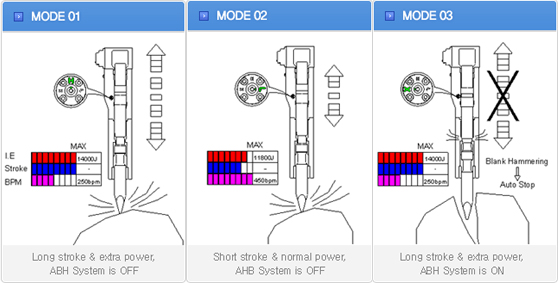

- IPC & ABH system Integrated Power Control & Anti-Blank Hammering System allows you to choose from 3 different modes

The automatic shut off function can be switched off or on. The operator can select the correct operating mode between high frequency and normal power or low frequency with extra power. With this advanced system, the operator can choose the correct mode in accordance with site requirements in a matter of minutes and with a minimum of hassle. - Improved vibration dampening system with triple absorbing points.

- Fully enclosed housing and dust protector.

- Auto shut-off & easy start

operation can be automatically stopped in order to prevent consequential damage to the power cell due to the blank hammering. This is especially useful in secondary breaking applications or when the operator is not skilled. Operation is easy to start when soft pressure is applied by the chisel to the work surface. - Locking device for the tie bolt nut.

- Auto lubrication connection.

- Convenient nitrogen gas charging and pressure check from the outside of housing. It is not necessary to open the service panel.

I.E : Impact Energy

Specification

Medium range

| Description | SQ60 | SQ70 | SQ80 | |

| Operating weight | Kg | 1263 | 1662 | 2013 |

| Carrier weight | ton | 15~18 | 16~21 | 18~26 |

| Height | mm | 2604 | 2670 | 2801 |

| Required oil flow | l/min | 90~120 | 100~150 | 120~180 |

| Operating pressure | bar | 150~170 | 160~180 | 160~180 |

| Impact rate | bpm | 600~850 | 500~850 | 500~700 |

| Tool diameter | mm | 125 | 135 | 140 |

Heavy-duty range

| Description | SQ100 | SQ120 | SQ130 | |

| Operating weight | Kg | 2185 | 2510 | 3033 |

| Carrier weight | ton | 25~30 | 28~35 | 30~45 |

| Height | mm | 2918 | 3194 | 3337 |

| Required oil flow | l/min | 150~210 | 180~240 | 200~260 |

| Operating pressure | bar | 160~180 | 160~180 | 160~180 |

| Impact rate | bpm | 430~580 | 430~580 | 380~550 |

| Tool diameter | mm | 150 | 155 | 165 |

| Description | SQ140 | SQ150 | SQ180 | |

| Operating weight | Kg | 3169 | 3950 | 5850 |

| Carrier weight | ton | 30~45 | 40~55 | 50~90 (100) |

| Height | mm | 3351 | 3575 | 3709 |

| Required oil flow | l/min | 200~260 | 210~290 | 300~400 |

| Operating pressure | bar | 160~180 | 160~180 | 160~180 |

| Impact rate | bpm | 300~500 | 320~470 | 300~400 |

| Tool diameter | mm | 165 | 175 | 197 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Suk Hyun Chung

- Address

- 260, Jeongmunsongsan-ro, Yanggam-myeon, Hwaseong-si, Gyeonggi-do, Korea

- Product Category

- Construction Machinery Parts

- Year Established

- 1984

- No. of Total Employees

- 101-500

- Company introduction

-

<p>Since our founding, over 30 years ago, Soosan’s single mission has been the design and manufacturing of innovative, technologically and cost-effective products. SOOSAN breakers are designed to provide optimal reliability and performance durability. Soosan engineers use exclusive stress analysis simulations software to test and ensure all critical components. SOOSAN’s Drills have greater working efficiency through expanded working ranges and higher drifter drilling speeds in comparison with competitive products. Additionally, their clean structural design, accessibility and user-friendliness improves operator comfort. The distinctive light weight cranes of SOOSAN are designed with specialty 3 mm alloy plates to reduce their weight by 10% while permitting the cranes to exert a stronger force with the same amount of hydraulic power.

The products of SOOSAN have been recognized and trusted by customers around the world, and it begins by using only the premium alloys and materials that undergoes strict quality testing. Heat treatment, a critical process to ensure breaker component durability is controlled in-house and under strict procedures refined over 30 years of heat treating expertise. All component machining and final grinding are conducted on the latest precision SPC equipment, and carefully monitored for precise tolerances. In the assembly process, only the latest generation robot welding machines are used As a final step in the quality process, all breakers are hydraulically tested to ensure finished products are ready for sale. SOOSAN has never settled for the status It continues its vision of innovation, customer-focused and investing in their future. The ultimate value of earning their customers trust is the reason that SOOSAN exists. Sincery for your business success.

- Main Markets

-

China

China

Germany

Germany

Netherland

Netherland

Qatar

Qatar

South Korea

South Korea

Turkey

Turkey

U.S.A

U.S.A

- Factory Information

-

260

- Main Product

Related Products

,_Smartphone_dryer,_heating_mobile_2.jpg)

Mobile Dryer, Smartphone dryer, heating chamber(RG-202)

Jet Fan(1800~2400CMH)

Marine Loading Arm

12V Kiosk and Receipt thermal printer HMK054

Korean children's clothing chichikaka brand