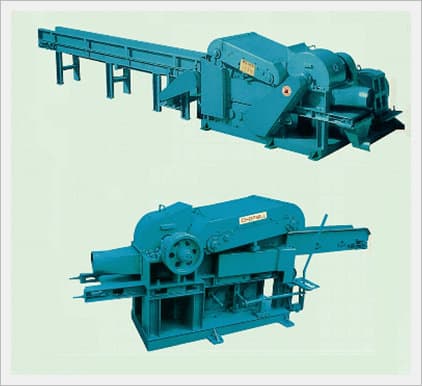

Fixed-type Sawdust Producer with Motor (CHOP Series)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Woodworking Machinery

Apply a video call to the Supplier

Serim Chopmill Co., Ltd

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

11

| Product name | Fixed-type Sawdust Producer with Motor (CHOP Series) | Certification | - |

|---|---|---|---|

| Category | Other Woodworking Machinery | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Features of Feeding Section

- The feeding section is largely composed of a wide, large hopper and a feeding unit. The feeding unit consists four individual upper rollers and lower rollers. Each upper roller is designed to move up and down or back forth independently. Unlike a machine having a feeding section consisting of one upper roller and a lower chain, therefore, this machine provides strong pressing force when feeding wood. Wet, twiggy, crooked, or bulky woods can be fed smoothly without slipping, or being caught or clogged. Woods fed are cut in a securely gripped condition. This machine offers high safety, low load factor, low wear of blade, uniform size of chips, and high productivity.

- Both walls of the feeding section is provided with a few rollers to prevent woods from being caught, so that woods can be fed smoothly without being caught or clogged even when they are fed excessively. Therefore, high production capacity and logn service life of the machine can be obtained.

- The feeding section is placed low in order to relieve a worker's fatigue and improve work efficiency.

Features of Cutting Section (Blade Drum)

- A drum is designed not only to crush woods but also to produce sawdust.

- The drum is also designed to both crushing blades and sawdusting blades to be installed. If both blades are installed, crushed chips are produced. If the crushing blades are removed, sawdust is produced. Blades can be changed easily and in a short time.

- A blade is long and its both sides can be used. As it can be ground five or six times for use, its average lifetime is six to twelve months, depending on working conditions. Therefore, the consumption of blades is so low that a cost-saving effect can be obtained.

Features of Blade Assembly System (patented and certified by KT)

- Blades, blade sheaths and a sheath groove base are designed to be separated from each other so that is is easy to disassemble and reassemble them. If a blade or blade sheathh is damaged by stone or metal, it is needed to replace such damaged blade or blade only. Therefore, low maintenance cost is required, and permanent lifetime of a drum is guaranteed.

- Each two blades are fixed into a 15° inclined blade sheath that is firmly wedged into a 45° inclined groove of the sheath base. During cutting work, blades are not vibrated so that the sheath groove is not worn away. Lifetime of a blade and blade sheath is semi-permanent.

- A blade sheath is designed to have a large discharging passage for sawdust and crushed chips in order to ensure smooth discharge of sawdust and chips. Blades and the drum are not heated as wind is generated from the drum. Therefore, long lifetime of the drum and blades are ensured.

In addition, uniform size of chips and low load factor result in high production capacity.

* The conventional machines have many problems such as vibration of blades due to its vertical assembly, overheating resulting from small discharging path around the blades, severe wear of blade sheath and blade cover plate due to vibration of blades, severe overload caused by wood residues such as resin sticking to the blades, short lifetime of a drum and blades due to overheating, and irregular size of chips.

However, Serim Chop Mill's machine has perfectly made up for these problems. It has also obtained the KT (Korean Technology) Mark in recognition of its quality and performance.

Features of Blade Assembly System (patented and certified by KT)

-

Chips crushed by drums and discharged along the feeding belt (patented by Serim) installed at the bottom of the machine are fed to a long loading conveyor attached to the rear of the machine. The conveyor's height can be freely adjusted according to the height of a carrying vehicle. This section is designed to keep the area around the machine clean, facilitate moving and loading works, and generate no dust. (It has obtained the certificate of an excellent product from the Korean Public Procurement Service.)

Specifications (Model's length is dimension without input conveyer)

| Model | Wood feeding type |

Cutting method |

Dimensions (mm) |

Weight (Kg) |

Materials and type of blade |

Size of feeding tray(mm) |

Adhesion Power (HP) |

Capacity per hour |

||||

| Length | Width | Height | W | H | sawdust | Chip | ||||||

| CHOP 200S |

Up-down Rolling Auto-transfer |

Drum Rotation Cutting |

2850 | 2350 | 1650 | 4500 | Double-side, dual carbide blade |

400 | 400 | Engine 360 Motor 214~268 |

47m3/h | 30~40 ton/h |

| CHOP 200A |

Up-down Rolling Auto-transfer |

Drum Rotation Cutting |

2850 | 2300 | 1600 | 4000 | Double-side, dual carbide blade |

350 | 350 | Engine 288 Motor 175~214 |

37m3/h | 20~30 ton/h |

| CHOP 201A |

Up-down Rolling Auto-transfer |

Drum Rotation Cutting |

2800 | 2250 | 1500 | 3500 | Double-side, dual carbide blade |

300 | 300 | Engine 185~250 Motor 150~175 |

25m3/h | 15~20 ton/h |

| CHOP 201 |

Up-down Rolling Auto-transfer |

Drum Rotation Cutting |

2750 | 2200 | 1450 | 2900 | Double-side, dual carbide blade |

250 | 250 | Engine 185 Motor 75~100 |

18m3/h | 10~15 ton/h |

| CHOP 202H |

Up-down Rolling Auto-transfer |

Drum Rotation Cutting |

2500 | 2150 | 1350 | 2200 | Double-side, dual carbide blade |

205 | 210 | Engine 69~88 Motor 60~75 |

13m3/h | 5~7 ton/h |

| CHOP 202 |

Up-down Rolling Auto-transfer |

Drum Rotation Cutting |

2400 | 2100 | 1200 | 1300 | Double-side, dual carbide blade |

200 | 170 | Engine 50~65 Motor 30~40 |

5~8m3/h | 3~5 ton/h |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Ho Young, Park

- Address

- #102, Kayari, Jinryang-eup, Gyeongsan-si, Gyeongsangbuk-do, Korea

- Product Category

- Woodworking Machinery

- No. of Total Employees

- 1-50

- Company introduction

-

We are the multipurpose recycle handling machine manufacture company.

Ever since its foundation in the year 1989, We, Serimchopmill Co., Ltd., contribute environment-friendly industry fields all the time.We manufacture wood crushers, sawdust machines, grinders, waste shredders, and screening machines.

- Main Product

Related Products

China Air fan

China Accessories of plasma torch

Double Over Head Milling Machine NDM-1500

CNC Woodworking Router

VIETNAM WOOD POWDER HIGH - QUALITY