Mega Thermal Conductive Coat, Liquid, Black

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Industrial Supplies , Building Coating , Other Paint & Coatings

Apply a video call to the Supplier

Ecoinfra Holdings co.,ltd

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

10

| Product name | Mega Thermal Conductive Coat, Liquid, Black | Certification | - |

|---|---|---|---|

| Category |

Industrial Supplies

Building Coating Other Paint & Coatings |

Ingredients | - |

| Keyword | functional polymer resin , incombustible ceramic coating , polymer concrete , mtcc | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

MTCC, Mega Thermal Conductive Coat, Liquid, Black

│What is the Mega Thermal Conductive Coat (MTCC) with graphene│

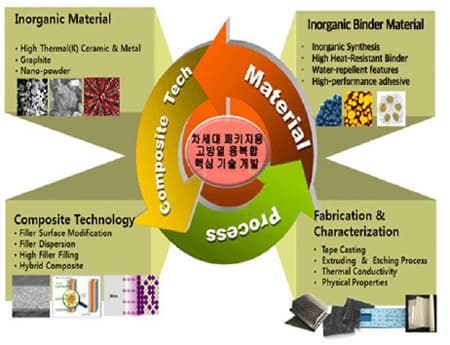

- High thermal-conductive material with graphene and inorganic binder made by Sol (Sol-gel)

method. MTCC have good thermal stability (up to 2000 ℃) and corrosion resistance (antioxidant). - The MTCC is the world's first production with unique process to separate graphene layer and graphene oxide layer. It can be easily coated with spray process.

- Until now, almost existing coating materials with organic or organic-inorganic hybrid ingredient cannot be used in high temperature. However, the MTCC could be used in very high temperature up to 2000 ℃.

- High thermal-conductive material made by unique separation process that could be possible to mass-production.

- Heat conductivity above 200~400W/m.K with 20~30um(0.02~0.03mm) thickness.

- High electrical conductivity above 3.55 3.55 S/cm

- High stability in acid and alkali, high thermal stability to max. 2000 ℃.

- Shield function to prevent disturbance of electromagnetic wave

- No deformation by biological attack, excellent anti-bacterial effect

- MTCC layers can be heated by far-infrared and microwave radiation.

- Good adhesive function on metal, nonmetal, plastic, FRP, carbon fabric, textile, film and glass

│Needs & problems of conventional coating material│

- Needs : High thermal conductivity & Stability at high temperature

- 95% of conventional thermal conductive material is organic and inorganic compound.

- The temperature range of organic or organic/inorganic compound is below 300℃, and it is difficult to use in high temperature range. - Needs : Easy formation of thermal conductive layer

- Conventional materials for heat-dissipation have problems with Thinning, limit of formation, because they have typical shape such as the film and the pad.

- Formation by attaching sheet is insufficient because the thermal paths could be jammed by adhesive and air-gap.

- The film attaching has limitation to form a linear or non-linear, circular, spiral shapes.

│Easy formation of thermal conductive layer│

- Stable MTCC over 1000℃ with graphene

- High stability in acid and alkali, high thermal stability material with graphene & ceramic

- applied to metal, nonmetal, alloy, FRP, textile, glass, film and concrete - Easy formation by spray coating method

- high bond-strength : 2MPa

- hardness : over 8H (Pencil hardness)

- Excellent effects for thermal dissipation from local-point heat-generation.

- various coating method : spray, Dipping, Roll coating

│Key tech. for thermal conductive material│

│Next-generation electronic devices and advanced material of graphene thermal conductive coat│

- Next-generation inorganic electronic device is thin, light, short, small and multifunctional but high density integration. Due to increase of heat density, the problem of thermal emission needs to be solved. Moreover, heat radiation system is an important factor because it is closely related to the reliability and lifetime of the device.

- Thermal conductive material of circuit board for high technology circuit board and a die attach and thermal spreader, high thermal conductive adhesive film and adhesive material, LED, rocket prepellants, car engines, marine engines, aircraft engines, gap filler radar, and all other require a solution to solve the heat problem of facility.

- Next-generation semiconductor package and high power LED package are experiencing low efficiency in active device and package destruction due to thermal stress. To solve this technical problem, the material of high thermal conductivity is needed to be developed urgently.

│The miniaturization and slimming of digital devices; the heat problem of IC, power and parts│

- Thermal conductive material is a core technology that highly influences the performance and lifetime of electronic devices.

- Due to rapid growth in demand for LED TV, the demand explosion for related materials is resulted.

Thus, we are highly depending on imports of thermal conductive material. - Because gold is used in the body of electronic devices, chassis and heat sink, the problem of heaviness and high price occurs.

│The market size and trend of thermal conductive materials│

- Market size : 11 hundred million dollars (2013) ? Ministry of Knowledge Economy

- The market size is rapidly growing due to the miniaturization and high performance of various devices.

- Highly depending on imports of high reliability boards and package from Japan

- Thermal conductive material is needed to be urgently developed for high efficient package used for semiconductor, automotive, LED, mobile, TV, computers, monitor and so on.

│The application of graphene thermal conductive coat│

- High thermal conductive material of circuit board:

solved by coating LED lighting, LED head lamps, automotive, PCB circuit board - High thermal conductive and thermoplastic package : solved by spraying instead of sheet type

- High thermal conductive adhesive material: solved by horizontally transferring heats of display parts (LCD, PDP, LED) and small IT devices

│Requirement of the application field and MTCC tech.│

|

Application Filed |

Requirement |

MTCC |

Reason |

|

Home appliance TV, heat sink for PC |

10W/m.K |

20 times |

Slimming home |

|

TV, PC, Cladding for Note PC |

3W/m.K |

70 times |

Slimming home |

|

Cladding for mobile |

3W/m.K |

70 times |

Increase in 3G service, Increase in importance of smart phone |

|

Thermal conductive mate rial for LED |

20W/m.K |

10 times |

Growth of 84 hundred million dollars in 2011 |

|

Light pickup |

5W/m.K |

40 times |

Low price |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Park Gihong

- Address

- #816, Doosan Venturesdigm, 126-1, Pyungchondong, Dongangu, Anyangsi, Gyeonggido, South Korea

- Product Category

- Coating & Paint,Industrial Supplies,Other Paint & Coatings

- No. of Total Employees

- 1-50

- Company introduction

-

systems, waste recycling, Architecture, civil engineering, offshore structures with the best technology in the field of To coexist with nature and people will build the world.

Eco Thermal Coat as microwave dielectric heating paint, MEGA Anti-flame as incombustible refractory material, MEGA Cera Coat as incombustible ceramic coating material, MEGA Slim Coat as ultra fine insulation material and Ecosol as eco-friendly inorganic adhesive, MEGA Cera binder as eco-friendly inorganic binder were developed by Ecoinfra Holdings in the field of new functional inorganic materials, in order to save the energy efficiency and protect from disaster.

The low permeability of our products allow it to be used in energy facillties that focuses on high energy efficiency, skyscrapers and civil engineering structures and vessels and industrial plants and residence facillties that concentrates on fire retardant insulation and sound proof. Moreover, We offer our products to use for firewalls and fire doors that make safety and fire retardant for energy facillties.

Ecoinfra Holdings will be contributed to implement innovative technology based on the microwave dielectric heating technology MEGA Polymer Concrete and MEGA Light Concrete and new inorganic materials in energy, building, and civil engineering, shipbuilding industry.

- Main Product

_2.jpg)