Cera Coat, Anti-corrosion coating, Liquid

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Home & Kitchen , Industrial Supplies , Building Coating , Other Paint & Coatings

Apply a video call to the Supplier

Ecoinfra Holdings co.,ltd

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

10

| Product name | Cera Coat, Anti-corrosion coating, Liquid | Certification | - |

|---|---|---|---|

| Category |

Home & Kitchen

Industrial Supplies Building Coating Other Paint & Coatings |

Ingredients | - |

| Keyword | functional polymer resin , incombustible ceramic coating , polymer concrete , mcc , mega | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

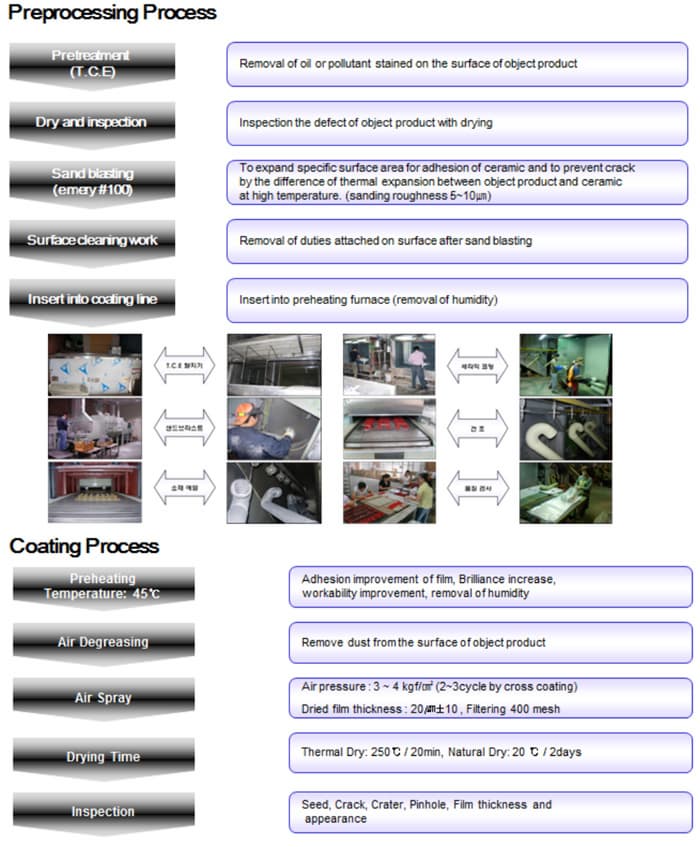

MCC, MEGA Cera Coat, Anti-corrosion coating, Liquid, Transparency

│Mega Cera Coat│

Heat Resistance, Anti-Corrosion

All In One Application !

MEGA Cera Coat is used a selected ceramic pigment which had proven by high temperature and an inorganic binder manufactured by sol-gel process with an excellent thermal stability. It is capable of withstanding temperature ranges from 500 to approximately 1300˚C. Its hardness(8~9H) is greater than exisitng paint (1~4H) due to vitrification form Si-O-H. thus, it is not only provides both of very good surface strength and durability but, also it provides an heat resistance and an anti-corrosion function including high-temperature corronsion.

Eco-friendly Coatings

Today, eco-friendly products are needed due to global warming and aicd rain that effect on the natural envrioment and industrialized areas. Thus, we developed eco-friendly noncombustible coating product which manufactured by sol-gel process. MEGA Cera Coat (MCC) has passed the industry's most stringent test for fire retardants (KS F ISO 1182)by Fire Insurers Laboratories of Korea.

High Heat Resistance (Temperature Ranges from 500 to 1300˚C)

Mega Cera Coat is formed a three-dimensional network structure through heating after coated a material. Thus, thermal stability is excellent.

Excellent Film Hardness (8~9H ↑)

It has formed the vitreous through lnorganic pigment and SiO2, which is more stronger (8~9H) than an exisitng paint hardness (1~4H)

Weatherability / Anti-contamination

Silicon-Oxygen bond energy indicates 101kcal/mol, which energy is higher than 83 kcal/mol of synthetic organic paint (C-C,C-H). Therefore, intermolecular bonds are not destoryed even if it is exposed to outside for longitme, are protected from hazardous gas and organic compounds. The static electricity is not generated due to the strong surface resistance. Moreover, the contamination which is caused by mist and exhaust gas is less, and recovery of cleaning is also better than other paints.

│Features│

- Eco-friendly : Eco-friendly inorganic ceramic binder is manufactured by sol-gel process

- High Thermal Resistance : Thermal stability is excellent, Usage temperature 1300˚C

- Hardness : Durable, Compact, High Hardness 8~9H

- Thickness : 20㎛±10㎛

- Non-combustible : Non-combustible coating material that uses pure binder which have proven by heat and fire resistance

- Durability : Si-O is stable to synthesized by sol-gel process. Long-life durability(10year+)

- Dry-to-touch : 20minutes after sprayed, Natural curing time 2 days, Curing temperature at 250˚C for 20minutes

- Function : Negative ion, Anti-bacterial effect, Deodorization, Far-infrared radiation, Anti-pollutant, Non-adhesiveness

- Anti-contamination : Resistant to corrosion from ultraviolet radiation, acid rain, dust, and exhaust

- Surface Resistance : Surface resistivity is extemely low, static-electricity free

- Self-cleaning : Excellent self-cleaning function that can be remove dust or exhaust

│Description│

|

Ingredient |

SiO2, AI203, etc. |

|

Non-volatile Content (N.V) |

50±5 Wt% |

|

Theoretical Standard Usage |

Approx. 1m²/150~200g(Board Coating) |

|

Specific Gravity (25/25˚C) |

1.2±0.1 |

|

Viscosity (25˚C/Ford Cup #4) |

11±1″ |

|

Particle Size (Grinding) |

Below 5㎛ |

|

Component |

One-part |

|

Storage Life |

6 months from the date of manufacture, Storage at 6±2˚C |

│Properties│

|

Item |

Test Method |

Standard |

Result |

Note |

|

Brilliance |

60˚C GLOSS METER |

ASTM D-523 |

30±5 |

Some difference depends on coating thickness |

|

Pencil Hardness |

MIT-UNIT Pencil |

7H |

8~9H↑ |

|

|

Adhesion |

Taping after Cross-Cut (1.5mm gap) |

100/100 |

100/100 |

|

|

Thermal Resistance |

500˚C/1HR |

There must not be crack or exfoliation |

None |

|

|

Film Thickness |

ELCOMETER-GUAGE |

20±5㎛ |

20㎛ |

|

|

Aicd Resistance |

5% CH3COOH/8hrs |

There must not be crack or exfoliation |

None |

25/25˚C |

|

Allcali Resistance |

1% NaOH SPOT/1hrs |

There must not be crack or exfoliation |

None |

Room Temperature |

|

Cloride Water Resistance |

5% NaCI/35˚C 8hrs ON,16hrs OFF |

There must not be corrosion or swell |

None |

|

|

Solvent Resistace |

IPA RUBBING TEST/1000g/100time |

Appearance, Gloss |

None |

Abrasivity |

│Standards│

- Ceramic cannot be overlaid on substrate and therefore the coated surface is removed by sandblaster

- Regulated Film Thickness (Dried film thickness 20㎛)

- 1 Coating 1 Baking System, No need for primer

- Spray Gun Nozzle Hole Size : ¢1.0~¢1.5

- Spray Air Pressure : 3~4Kgf/cm²

│Caution│

- Substrate must be removed foreign substances by 400 mesh for the ripened ceramic coating material

- Sediments must be removed to stir for 10 minutes with stirrer of 500rpm before use the ripened ceramic coating material

- The high pressure feeder is used to transfer a coating material and keep to equal coating material by mixer

- Ambient temperature is above 8˚C and preheating must be higher(3˚C+) than the dew point temperature to avoid the moisture condensation for thick materials

- The regulated pot life must be observed to achieve a excellent result

- Feedstock Inlet must be cleaned including spray booth, preheating furnace

- Ensure sufficient ventilation when working with coating material. The respiratory protective equipment should be provided and worn in confined space

- Do not mix with Oil-based materials. Do not use MEGA Cera Coat and other oil-based coating materials in parallel.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Park Gihong

- Address

- #816, Doosan Venturesdigm, 126-1, Pyungchondong, Dongangu, Anyangsi, Gyeonggido, South Korea

- Product Category

- Coating & Paint,Industrial Supplies,Other Paint & Coatings

- No. of Total Employees

- 1-50

- Company introduction

-

systems, waste recycling, Architecture, civil engineering, offshore structures with the best technology in the field of To coexist with nature and people will build the world.

Eco Thermal Coat as microwave dielectric heating paint, MEGA Anti-flame as incombustible refractory material, MEGA Cera Coat as incombustible ceramic coating material, MEGA Slim Coat as ultra fine insulation material and Ecosol as eco-friendly inorganic adhesive, MEGA Cera binder as eco-friendly inorganic binder were developed by Ecoinfra Holdings in the field of new functional inorganic materials, in order to save the energy efficiency and protect from disaster.

The low permeability of our products allow it to be used in energy facillties that focuses on high energy efficiency, skyscrapers and civil engineering structures and vessels and industrial plants and residence facillties that concentrates on fire retardant insulation and sound proof. Moreover, We offer our products to use for firewalls and fire doors that make safety and fire retardant for energy facillties.

Ecoinfra Holdings will be contributed to implement innovative technology based on the microwave dielectric heating technology MEGA Polymer Concrete and MEGA Light Concrete and new inorganic materials in energy, building, and civil engineering, shipbuilding industry.

- Main Product