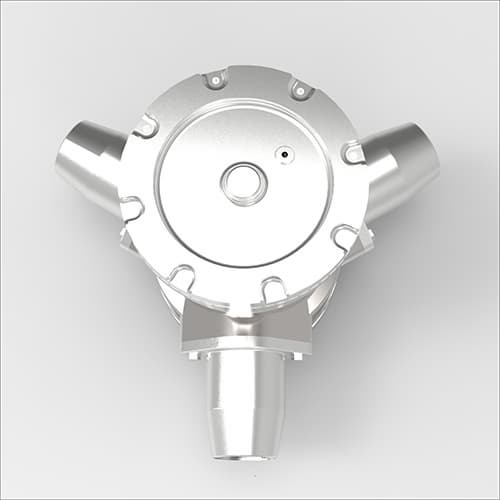

Rotary Jet Mixer(NK-SA08)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- NeoTechKorea

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Petrochemical Related Products

Apply a video call to the Supplier

NeoTech Korea

- Verified Certificate

-

10

| Product name | Rotary Jet Mixer(NK-SA08) | Certification | - |

|---|---|---|---|

| Category | Other Petrochemical Related Products | Ingredients | - |

| Keyword | rotary jet mixer , crude oil storage tank , crude oil jet mixer , tank pontoon swivel joint | Unit Size | - |

| Brand name | NeoTechKorea | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8481 |

Product Information

Rotary Jet Mixer(NK-SA08)

1. EQUIPMENT DESCRIPTION

1.1 Principle

The principle of this equipment is to prevent the accumulation of sludge on the bottom of the crude oil

storage tank using high discharging oil circulating pump, NEOTECHKOREA's rotary jet mixer. The high discharge

pressure of jet mixer breaks the sludge into small pieces after which the sludge is decomposed and

dissolved in the crude oil while the sludge floats up.

1.2 Characteristics of crude oil storage tank and sludge

Oil storage tank

The asphalt, tar, wax, etc. in the crude oil deposit on the bottom of the tank while the oil is stored in

the tank and these deposits become high viscosity sludge. It is hard to remove the sludge except

mechanical crushing or chemical dissolving methods. Due to the oil washing system, all sediments

such as rust, scale, mud, sand, etc. in the cargo oil tank flow into the storage tank. As the sludge

accumulates, many problems occur such as oil loss and reduced storage capacity of tank.

Sludge

The sludge contains 80-90% of oil and wax which are useful to recycle. Depending on the place of the

oil production, oil contains inorganic substances such as sand, mud, iron; sludge containing oil, water,

emulsion; organic substances such as oil, wax and asphalt. If these compositions of sludge sediment

on the bottom of oil tank, the following problems will occur.

- Reduction of tank storage capacity.

- Corrosion of tank bottom due to the water in the sludge.

- Incorrect gauging of tank.

- Increased cost for maintenance, repair and cleaning.

- Potential risk in case of floating roof.

- Disposition of sludge when inspecting open tank.

1.3 Merits of installation of jet-mixer (NK-JETMIXER)

The following effects are anticipated if the problems due to sludge accumulation in 1.2 are solved.

① Economical effects

- Efficient control of tank storage capacity.

- Reduction of maintenance cost and time.

② Merits of installation

- Correct measurement of oil storage quantity.

- Excellent oil drainage during oil discharge.

- Stable lowering of floating roof.

- Unnecessary oil pre-treatment process.

- Cost reduction compared with motor driving propeller.

- Good for operation of heat exchanger and desalination machine.

③ Stability

- No oil leakage as it is installed in the tank.

- Easy to analyze the cause of problems when problems occur in the equipment.

- Simple structure and excellent durability.

- Low noise and possible to operate in the evening.

- No risk of fire or explosion by electricity as it is immersed in the oil.

1.4 Key parameter

- The following specifications apply to the Machine:

- Nozzle Selection

These range from 55mm(2.17˝) to 115mm(4.53˝).Nozzle size selection is based on required jet range,

available pressure and flow rate for JET-MIXER Machine service.

- Impeller Selection

The speed of rotation can be varied by the flow rate through the Machine and also by a variety of

factory fitted impellers. The speed range being 1.78 – 5.18 deg. Min.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- KyeongRo Lee

- Address

- 112-701, 10Ho 348, Byeon-Gil, Nedong-Ro,Jinju-City, Kyungnam, Korea

- Product Category

- Other Machinery & Industry Equipment,Other Security & Protection Products

- Year Established

- 2013

- No. of Total Employees

- 1-50

- Company introduction

-

We are specialized in the manufacture of pressure and vacuum relief valves and flame arresters, as well as safety protection devices for liquid petroleum and petroleum products storage tanks, treatment, nitrogen blanketing systems for automatic nitrogen sealing devices, explosive venting systems, and other related products. All NEOTECHKOREA products are designed, manufactured and tested in accordance with API 2000, API 650, API 2521, API RP 520, EN12874, BS 7244 and other relate recognition code or purchase order specification. For the customer’'s safety, convenience and prosperity, we have been studying every aspect of storage tank & protection equipment and developing several methods ranging from field application to new products for higher safety standard since our foundation in 1999. All the staffs of our company are making every effort to make quality products to meet the needs of customers, through continuous technical development. Corporation NEOTECHKOREA’s quality management systems have been assessed and certified by ABS Quality Evaluation Inc. of Houston of USA and our products are manufactured in accordance with the requirement of ISO 9001 quality assurance procedures and assessed under strict quality standards before delivery to our customers. We promise to do our best to give our customers satisfaction, from the engineering of the high world standard to perfect after-sales service. As you are well aware, we are in a good position to export our quality products to global markets at reasonable prices with attractive delivery terms. In this regard, we would like to invite you to visit our homepage at <a href="http://www.corpwin.com">www.corpwin.com for reviewing our company’s profile and activities in advance. If you like to know more about our company, please do not hesitate to contact us at your earliest conveniece

- Main Markets

-

Australia

Australia

China

China

Singapore

Singapore

Taiwan

Taiwan

Thailand

Thailand

- Main Product

Related Products

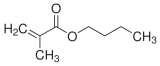

N-butyl methacrylate

TOLUENE

Low Molecular Polymer (LMP, PE-Wax)

4R insulation cover

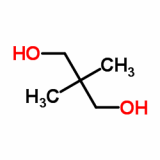

NEOPENTYL GLYCOL

South Korea

South Korea