Laser Welding Machine_LWI V Flexx Unixx III

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Germany

- Brand name

- Vision Lasertechnik GmbH

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Industry Laser Equipment & Parts

Apply a video call to the Supplier

Vision Industries Korea LLC.

- Verified Certificate

-

9

| Product name | Laser Welding Machine_LWI V Flexx Unixx III | Certification | - |

|---|---|---|---|

| Category | Industry Laser Equipment & Parts | Ingredients | - |

| Keyword | laser welder , laser welding machine , laser welding system , laser welding equipment | Unit Size | 1700.0 * 1800.0 * 1300.0 mm |

| Brand name | Vision Lasertechnik GmbH | Unit Weigh | 500 kg |

| origin | Germany | Stock | - |

| Supply type | - | HS code | 851580 |

Product Information

When working on very big pieces...

This unit has been developed for areas where the laser work shop needs to be prepared for any type of job. Regardless of whether thousands of small pipes need to be welded or cut today and a three ton mould delivery tomorrow, the UNIxX III will fulfils any task with the highest precision.

The many software tools provided will ensure speedy and high precision processing.

The range of 700mm in the x axis and 400mm in the y axis enable you to process big components without the necessity of them being repositioned.

Small pieces with the weight up to 300kg can be processed on the working table aforementioned in UNIXX and the working position pivoted accordingly.

The positioning and height of the working table has been designed to level with a normal office chair to allow one to sit and work ergonomically, and provides enough legroom. The sturdy table tipped at a well positioned angle ensures that there are no obstacles in your way.

When working on very big pieces, the working table can simple be swivelled to the side to allow the component to be placed under the laser by forklift. The extended range length enables you to reach the area to be repaired quickly.

The head is equipped with a bracket allowing for rotation of the laser head and enables you to weld on edges and angles.

Highlights

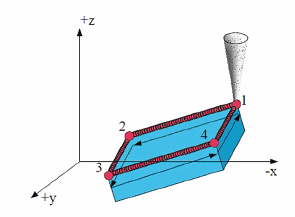

CAN-Step: The intelligent axis control

Precisely controls axis movements. This extends manual welding by its sophisticated automatic and programable functions. Touchscreen and Joystick terminals directly in your workspace provide a unique, simple control concept. Thanks to the completely integrated hardware, a separate computer is not needed.

PDS – Pulse Distance Synchronization

Enables the handling of complicated geometries in four axis without complex programming. A small number of support points are hit once on the contour of the work piece in advance. The user can subsequently move the programmed welding line forward and backward using the joystick and can also shift its position by offsetting the start point.

„Teach in“ programming

Enables the handling of complicated geometries in four axis without complex programming. A small number of support points are hit once on the contour of the work piece in advance. The user can subsequently move the programmed welding line forward and backward using the joystick and can also shift its position by offsetting the start point.

PCD – 3 Point Cycle Definition

You can process circular type contours by using the PCD function with the XY axis. The circular path is precisely defined through the teaching of only three support points. You do not need to know the center or the diameter; the position on the work piece is optional. You can move along the programmed course either forward or backward by using the joystick.

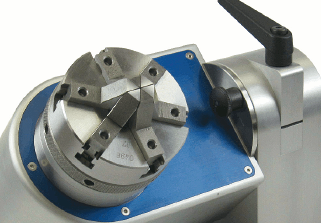

Combinable with a rotating device

Specially developed turning units increase the user value of your workstation. They incorporate all functions of CAN-Step control, available at the touch of a button, including pulse synchronization and „Teach in“ programming. Additional features: • Swivel-mounted • Free implementation up to Ø40 mm • different chuck types, chucking range up to Ø 160 mm.

Integrated work table with aperture

The useful high load capacity work table can be revolved under the laser head. The plain-milled slot profile worktop can be rotated and is locked. Supports and worktops provide free lead through. This allows you to weld long work pieces smoothly.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Ingeun Choi

- Address

- 22-1, Siheung-daero 935beon-gil, Siheung-si, Gyeonggi-do 14956, Korea

- Product Category

- Industry Laser Equipment & Parts

- Company introduction

-

Global Laser welding & marking machines

- Main Markets

-

Brazil

Brazil

Thailand

Thailand

Viet Nam

Viet Nam

- Main Product

Related Products

HIPRO (HIFU)

10W 20W 30W 50W Fiber laser marking machine

Ultra-Pulse CO2 Laser: SNJ-1000U

CO2 Laser Power Meter Probe 100 watts

K2UV SERIES UV MARKING LASER MACHINE

South Korea

South Korea