Smart rework system-Shield can, image sensor

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Others,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery Parts

Apply a video call to the Supplier

regeni

- Verified Certificate

-

9

| Product name | Smart rework system-Shield can, image sensor | Certification | CE |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | bga rework station , rework system , repair equipment , repair bga pcb | Unit Size | 380.0 * 260.0 * 230.0 mm |

| Brand name | - | Unit Weigh | 7 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8486904020 |

Product Information

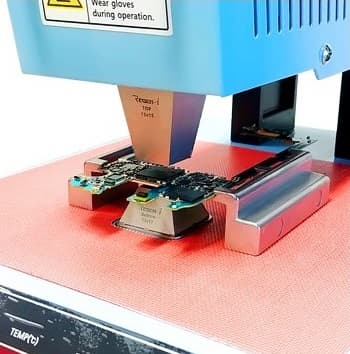

SMART REWORK SYSTEM (BK-200S)

1) Purpose of Use

This product is manufactured with purpose of replacement SMD part for Smartphone PCB and

Small PCB under 200 mm(W*D) size.

2) Features

① This Rework system’s simple design delivers highly user friendly operation.

② This is available adjustment in 3 Steps for Temperature and Time.

③ This is easy PCB mounting by magnetic fixing block.

④ This is simple PCB relocation by applying sliding way for Nozzle movement.

⑤ It is possible to realize temperature graph that cannot be implemented in hot gun.

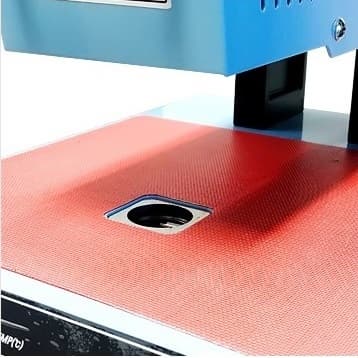

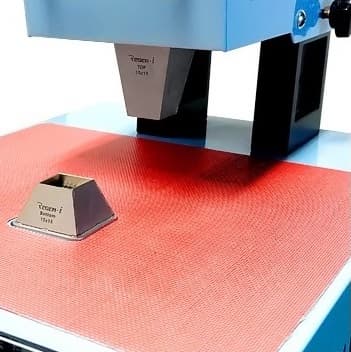

3) Product appearance

※ Basic Nozzle provided

4) How to operate

① Nozzle Installation

Install tightly so that there is no gap in the heat outlet of the upper heater.

Lower Nozzle(Magnetic)

Upper Nozzle(Magnetic)

② PCB Mounting

Slide the upper heater backward to the end.

Match the center of the Work-piece to the center of the lower heater by using 6 kinds of magnetic PCB fixing blocks.

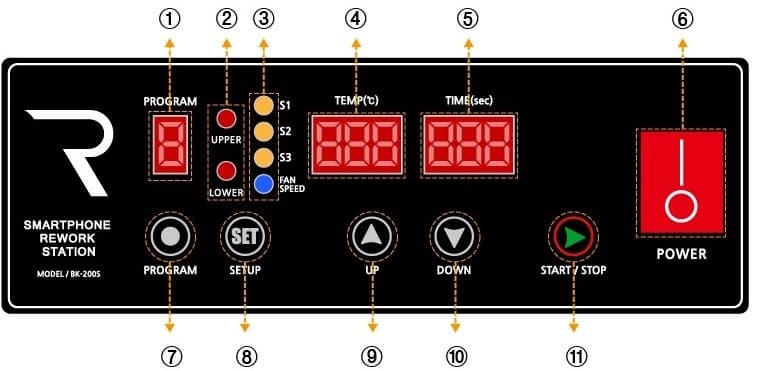

③ Control Panel

① Program number is displayed for current applied program

(Program number: 1~5(Pre-programed) / 6~9(User’s set up)

② At standby, the upper and lower parts are cross-lighting. When the upper lighting, the current temperature of the upper heater is displayed. When the bottom lighting, the current temperature of the bottom heater is displayed.

③ Program value division for user using program number from 6 to 9.

④ Current temperature display by stages

⑤ Remaining time display by stages

⑥ Power switch

⑦ Selecting program (#1~5: pre-programed by factory, 6~9: available by user’s set up)

⑧ To change the temperature, time and airflow settings of user’s set up only for program number 6~9

⑨ Button to increase numerical value

(When heating in the third step, remaining time can be extended by 30 second per one

pressing)

⑩ Button to decrease numerical value

⑪ Start and Stop for operation.

④ Initial program setting

① Graph

② Default value(Factory setting)

Prog. | Sort | Step1 | Step2 | Step3 | Applied parts |

1 | Temperature | 100 | 180 | 230 | E.T.C |

Duration time | 30 | 50 | 50 | ||

2 | Temperature | 110 | 190 | 240 | MIC, IF |

Duration time | 30 | 50 | 50 | ||

3 | Temperature | 120 | 200 | 250 | IF, BAT CON |

Duration time | 30 | 50 | 50 | ||

4 | Temperature | 130 | 210 | 260 | IC, POP, MEMORY |

Duration time | 30 | 50 | 50 | ||

5 | Temperature | 140 | 220 | 270 | E.T.C |

Duration time | 30 | 50 | 50 | ||

6~9 | Temperature | TEMP.1 | TEMP.2 | TEMP.3 | User setting |

Duration time | TIME 1 | TIME 2 | TIME 3 | User setting |

⑤ Start and Stop for heating

① Heating Start: Heating is started based on the selected program. From the current temperature to the set temperature of STEP1, temperature is increased at 3 degree per second. When set temperature is reached, the temperature is maintained for a period of time of setting values. After that, heating is carried out according to the set values of STEP2 and STEP3.

② Extension time: Each time the "UP" button is pressed once in STEP3, the heating holding time can be further extended by 30 seconds.

③ Stop: When you press the Stop button to terminate the heating operation, upper and lower heater will cool down to 40 degree. After that, cooling function will stop and the system will switch to standby mode.

④ Restart: When you resume the heating operation after pressing program stop button, the heating does not proceed at temperature higher than 80 degree even if start button is pressed. As the temperature drops to 80 degrees or less, the heating operation can proceed.

⑤ Heating Pause of Upper heater: In order to stop the heating of the upper heater during operation, if the upper heater is pushed back about 4 cm, a physical weak jam is confirmed and its power is cut off. The fans will continue to operate and "UP" and "OFF" will illuminate on the temperature display. At this time, the program in progress is continued, and when the upper heater is pulled forward again, the pause function is canceled and the Upper heater begins to rise to the temperature of the current ongoing stage.

* Magnetic fixing blocks provided.

5) Specification

Product Name | Smartphone Rework System |

Model | BK-200S |

Power | AC 200~240V 50/60Hz |

Max Watts | 1600 [W] |

Max Current | 7 [A] |

Size | (L)380mm x (W)230mm x (H)260mm |

Weight | 7kg |

Country of Origin | MADE IN KOREA |

1. Troubleshooting

1) When the product does not turn on

① When smoke is emitted from the upper heater or the lower heater during operation. Power off immediately and ask for A/S consultation.

② Check the power supply.

③ Make sure if the upper heater is pushed backward.

(At the start of heating, the upper heater must be fully pulled to the front.)

④ Check if it is not a power failure.

2) When temperature does not rise.

① Check if the temperature rises during heating.

② Make sure if the upper heater is pushed backward.

(At the start of heating, the upper heater must be fully pulled to the front.)

③ Check the operation statues of heater.

3) Error message

During malfunction, three times of buzzer sound, “beep” and error

message will be displayed as below.

① "UP" "th": Defective thermal sensor of Upper heater

② "LO" "th": Defective thermal sensor of Lower heater

③ "U-H" "OFF": Improper temperature rise of Upper heater

④ "L-H" "OFF": Improper temperature rise of Lower heater

5) Specification

Product Name | Smartphone Rework System |

Model | BK-200S |

Power | AC 200~240V 50/60Hz |

Max Watts | 1600 [W] |

Max Current | 7 [A] |

Size | (L)380mm x (W)230mm x (H)260mm |

Weight | 7kg |

Country of Origin | MADE IN KOREA |

- Product Info Attached File

- Verified Certificate

-

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Others,T/T | Shipping time | Negotiable |

- President

- Leem Chae Youl

- Address

- 648 Seobusaesgil Geumcheon-gu, Geumcheon-gu, Seoul, Korea

- Product Category

- Electrical Supplies

- Year Established

- 2005

- No. of Total Employees

- 1-50

- Company introduction

-

Leapinginto the world and making the futureWith Best Product! Best Technical Support! Best Action Time!In order to develop technology and content suitablefor the needs of the era, Regen-i Co., Ltd. operates an active organizationalmindset and affiliated research institute. Based on this, we secured 33 patentsand intellectual property rights as of 2016.We are leading the market share of standardizedrepair equipment for Smart phones since 2012 with constant technologicalinnovation and have been delivering our products to approximately 4,000branches in 30 countries overseas since 2013.Above all, we promise to do our best to satisfy ourcustomers and partners.2017 ~Feb: Designated by NICE as an excellent technology evaluationcompany by industrial equipmentApr: Development of both Rear Cover Disassembly jig(RG-250) andSmartphone Compression system(RG-260) for LG Electronics G6 model andCompleting delivery of its service center2016 ~Jun: BGA REWORK SYSTEM Delivered to LG Electronics Service centers (80units)Jun:.06 Accomplished to 600 units cumulative sales volume of BGA REWORKSYSTEM2015~Feb: Participated in Hong KongWorld IT ShowApr: Participated in Singapore Security ShowDec: Reached to 5,000 units Exports of Mobile dryers2014 ~Apr: Participated in NEPCON KOREA Exhibition (COEX)2013 ~Oct: Delivered to 200 Samsung Service Centers for BGA REWORK SYSTEM2012 ~Apr: Participated in NEPCON KOREA Exhibition (COEX)Aug: Participated in KINTEX Exhibition2011 ~Feb: Registration of Best Korea trademark and service markJul: Establishment and registration of Regen-i Research Institute

- Main Markets

-

Brazil

Brazil

Czecho Republic

Czecho Republic

Germany

Germany

Netherland

Netherland

Turkey

Turkey

U.S.A

U.S.A

- Main Product

Related Products

RC Level Rod

OSTEOTOMES

Knitted wire mesh Gaskets Seals

Wrapping Scale machine

FAG NTN NSK KBC bearings

South Korea

South Korea

,_Smartphone_dryer,_heating_mobile_2.jpg)

_2.jpg)