Cored Wire

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Wires & Cables

Apply a video call to the Supplier

Seokang Metal Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | Cored Wire | Certification | - |

|---|---|---|---|

| Category | Wires & Cables | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Cored wire usage

- Calcium treatment Aluminum-killed clean steel

In case of Al-killed grades, the steel bath contains high melting point Al2O3 inclusions which can lead to nozzle clogging at the continuous caster, poor transverse mechanical properties after rolling, bad resistance to HIC and bad machinability. The addition of Ca during ladle refining transforms Al2O3 into(CaO)x(Al2O3)y which has a low melting point and also remains globular during rolling, thus eliminating the above problems. - Trimming additions

Due to the high and stable recovery of additions practiced by way of cored-wire, a very accurate and reproducible steel chemistry can be achieved which in turn permits to optimize the mechanical properties and / or heat treatment as well as eliminate rejection or downgrading of heats out of the chemistry specification. Most popular for this purpose are cored-wires containing carbon, sulfur, manganese, FeTi

Cored wire purpose

- General advantage of cored wire addition

During cored-wire injection, the content powder is released close to the ladle bottom, far away from oxidation sources (slag, air) and under high ferrostatic pressure. This leads to a better recovery compared to traditional lump or powder additions, especially for elements which are highly oxidizable have a high vapour pressure and / or a low density. - Phase-diagram

CaSi wire addition to Aluminum- Silicon deoxidized grades permits to achieve very plastic inclusions of the Anorthite type which are favourable to deep drawing (in wire rod for instance) and machinability.

A limited Ca or CaSi wire input can solve Ti02 nozzle clogging problems at the CC on Titanium stabilized stainless steel grades.

CaSi Wire addition on Silicon- Manganese deoxidized steels with a low Mn/Si ratio can avoid nozzle clogging problems created by high melting point Manganese-Silicates and limit the scum formation which is detrimental to surface quality.

Standard final Products

| Type | Size(out*in*width)(mm) | Length(m) | Remarks |

| Cage | 1100 x 600 x 700 | 3100 |

|

| 1100 x 600 x 1100 | 4250 | ||

| 1150 x 600 x 1100 | 5300 | ||

| 1300 x 600 x 1100 | 7150 | ||

| 1500 x 600 x 700 | 6050 | ||

| 1500 x 600 x 700 | 9550 | ||

| Reel | 1050 x 560 x 448 | 1500 | |

| 1210 x 560 x 448 | 2100 |

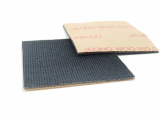

Reel Type

|

|

| Wood | Steel |

Cage Type

|

|

| Vertical type | Horizontal type |

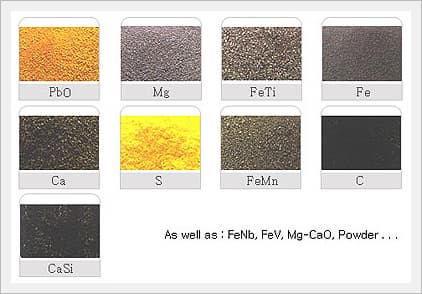

Usual Product

| PureCa Wire | CaFe Wire | CaSi wire |

| Fe Ti Wire | Carbon Wire | Sulfur Wire |

| BiMn Wire | FeMn Wire | Mn Wire |

| Slag Wire | CaAl Wire | Mg Wire |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- EUM, Kwangho

- Address

- 146, Ochun-rI, Younil-eup, Nam-gu, Pohang-si, Gyeongsangbuk-do

- Product Category

- BBQ

- No. of Total Employees

- 1-50

- Company introduction

-

It is my great pleasure to address our precious customers of SeoKang Metals Co., Ltd. in this new newly designed homepage.

It has been almost twenty years since we engaged in the business of manufacturing steel products. But we are always in the same spirit as when we were starting. Started in 1986 as SeoKang Co., Ltd, we have produced recarburizer, which are essential raw materials in steel making industry, and also developed cored wires for the first time in the nation.

Thanks to outstanding performance we have been successful in positioning SeoKang Metals Co., Ltd. as a primary supplier in the business, both at home and abroad. Our products are very competitive in price and quality, providing our customers with pleasure and satisfaction. Encouraged by your continued supports, we are doing our utmost best to produce better products more cost-effectively.

We look forward to your continued patronage and encouragement.

Thank you.

- Main Markets

-

Japan

Japan

- Main Product