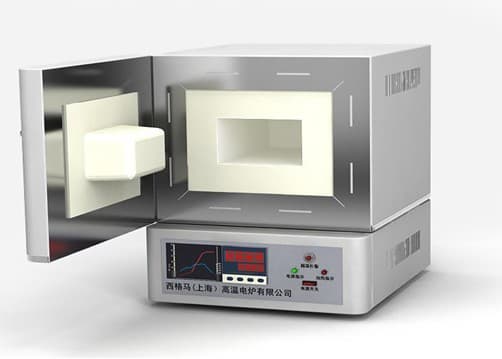

Mini Muffle furnace for lab heat treatment

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- Sigma

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

Apply a video call to the Supplier

Luoyang Sigma Instrument Manufacture Co.,Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

11

| Product name | Mini Muffle furnace for lab heat treatment | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | heat treatment furnace , industrial furnace , lab furnace , muffle furnace | Unit Size | - |

| Brand name | Sigma | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Artificial intelligence box resistance furnace (muffle furnace)

1000℃-1200℃

SGM series of high-temperature laboratory furnaces have the perfect design, possess many patents, the safety, reliability and practicability of which all show the best performance.

1. The highest working temperature 1000℃/1200℃

2. Adopting vacuum forming technology, furnace wire embedded in the inner surface of ceramic fiber furnace chamber, one-step forming liner of furnace chamber could prevent suffering the pollution of volatile matter.

3. Furnace wires are set in the four sides of the furnace chamber, special surface treatment anti-corrosion technology to furnace wire.

4. The patent processing technology of gradient ceramic fiber, special insulation design, the temperature of furnace shell surface is low.

5. Designed with the following functions:

SCR control; transformer regulating; PID parameter self-setting; manual or automatic switch without interference; 30 programmable periods; continuously constant temperature and temperature control; automatically power off when the furnace door is opened; over-temperature alarm; the built-in parameter password to control the furnace;

6. Heating rate is 10-30℃/min, fast heating rate, low energy consumption in the condition of empty furnace, energy saving is more than 50%.

7. High precision temperature control, display accuracy:±1℃, over temperature value is less than 3℃, temperature uniformity: ±6℃.

8. Multiple safety protection design with good safety and long working life conforms to CE Safety Certificate.

9. Side opening door (opening the door from one side), easy to use, simple operation.

10. The patent shape design, full-door structure, beautiful appearance

11. Rated voltage is 110V and frequency is 50 HZ.

Optional configurations:

1. The observing hole where users can watch the heating process inside the furnace;

2. Exhaust chimney

3. Furnace bottom plate

4. The function of power off by opening the furnace door

5. The function of 30 programmable periods

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Luoyang Sigma Instrument Manufacture Co.,Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

11

- President

- Sen'an Zhou

- Address

- Sanyuan Road, High-Tech District, Luoyang , Henan , China

- Product Category

- Electrical Components & Telecoms,Machinery & Parts,Other Machinery & Industry Equipment

- No. of Total Employees

- 101-500

- Company introduction

-

Founded in 1999, Luoyang Sigma Instrument Manufacture Co.,Ltd is a high-tech enterprise specialized in R&D and manufacture of all kinds of muffle furnace, industrial furnace, tube furnace, vacuum furnace and high temperature furnace etc.

Sigma has the right to the use of 40 acres industrial land and owns 8000 m2 standardized plant and office buildings, 1500m2 administrative and marketing center and 1500m2 ultra-high temperature engineering and technical research and development center. It also possesses four advanced production lines of lab furnace, industrial furnace, ceramic fiber board and furnace chamber, and ultra-high temperature ceramic fiber.

In 2006, our company was the first one to develop the ceramic fiber type artificial intelligence box resistance furnace and regarded the over temperature value of 1-3 degrees Celsius as one of the standards to control the temperature in box resistance furnace, the comprehensive performance of which reached the advanced level of the international brand. Sigma, therefore, becomes a well-known brand in laboratory industry.

In 2007,our furnace were rated “quality stability and after-sales service satisfied products” by Quality and Technological Supervision of Henan Province.

In 2010, our company invented the diorite and zirconium composite ceramic heating elements and thermocouples, the maximum working temperature of which can reach 2600 degrees Celsius. These ultra-high temperature sensors can work under both vacuum and oxidizing atmosphere, marking the history of measuring the maximum temperature in contact-type under oxidizing atmosphere.

In 2011, our company set up an Ultra-high Temperature Sintering Experiment and Engineering Center engaged in various sintering experiments at the range of 1000-3000 degrees Celsius, becoming the first high temperature laboratory available to domestic and abroad in China.Up to now we have got 50 technology patents and intellectual properties. As the manufacturer we have passed the ISO 9001:2008 International Quality System Certifications and can provide the OEM/ODE service.

- Main Markets

-

Australia

Australia

France

France

India

India

Iran

Iran

Russia

Russia

Singapore

Singapore

South Korea

South Korea

U.S.A

U.S.A

- Main Product

Related Products

AIS3000 HD

12V KIOSK THERMAL Printer Mechanism(Module) and Board 2inch

Airless Pump (Ratio 63:1 Airless Pump)

AIRLESS PUMP- YL 731

New High Pressure Exhaust Fan(30cm)