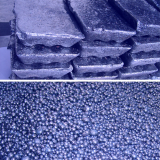

Micro Grain Carbide 4 Flute Corner Radius End Mills

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- corner radius end mills, micro grain carbide 4 flute corner radius end mills, carbide 4 flute corner radius end mills, 4 flute corner radius end mills

- Category

- Other Minerals & Metallurgy Products

Apply a video call to the Supplier

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

9

| Product name | Micro Grain Carbide 4 Flute Corner Radius End Mills | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | corner radius end mills , micro grain carbide 4 flute corner radius end mills , carbide 4 flute corner radius end mills , 4 flute corner radius end mills | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Tungsten carbide end mill is used for milling, with one or more of the rotary tool cutter.The margin in workpiece is cut by the mill intermittently. Carbide end mill is mainly used in processing plane, steps, grooves, forming the workpiece surface and cutting and so on.

There are two common materials for manufacturing end mill: high-speed steel, and tungsten carbide. Carbide end mill has relatively higher hardness, stronger cutting ability, and can improve the speed and feed rate as well as increasing productivity.

A tungsten carbide end mill is a type of industrial tool used for cutting and shaping metals and other solid materials. Though its appearance is similar to that of a drill bit, an end mill can cut in all lateral directions as well as axially like a drill bit. End mills are often made from carbide, also called tungsten carbide. Carbide is a very tough and heavy material that can cut metal without breaking or scratching.

The tungsten carbide end mill is one of several types of milling tools that are commonly used. Tungsten carbide end mills are distinguished from other types because they have cutting teeth at one end as well as on the sides. Tungsten carbide end mills also have one or more “flutes,” meaning deep helical grooves that run up and down the cutter.

The helical shape of the flutes gives two advantages. First, as the teeth cut through the material, chips are pulled away from the cutting surface by the rotation of the flutes. Secondly, the helix shape reduces vibration and gives a more polished finish than if the whole cutting tooth impacted the material at once.

Depending on the material that is being milled, and how the milling is to be done, there are many types of tungsten carbide end mill, with different shapes and geometries. For instance, if the material to be cut is a hard metal like stainless steel, shallow flutes and a square cutting edge will be optimal. With a softer metal like aluminum, deeper flutes with sharp cutting edges will be advantageous.

High speed steel was the traditional raw material for end mills, but most are now made of tungsten carbide. This is a highly rigid material that is extremely wear-resistant, giving a tungsten carbide end mill a longer life than a steel one. Some of the more impressive properties of carbide include its high melting point, at 5,200 degrees Fahrenheit (2,870 degrees C). It also measures about 8.5 to 9.0 out of 10 on the Mohs scale of mineral harness. By comparison, hardened steel only measures seven to eight.

Because of the precision required in its manufacture, a tungsten carbide end mill will usually be made by computerized machines. Inside the machine, the mills are ground by abrasive wheels mounted on spindles. The wheels are made with industrial diamond, one of the few materials on earth that is harder than tungsten carbide. Temperatures in these grinding machines are kept at bay with high-pressure lubricants, which include oils, oil-water emulsions, and sometimes plain water.

Main application of carbide end mill

It is mainly used for CNC machining centers, cnc engraving machines generally.

It can also be fitted to some common hard milling equipment for processing uncomplicated heat treatment Material

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

Related Products

Raw Wool

Marine Loading Arm

API 5CT Coupling

Phosphor Copper Master Alloy

Wire Rope Forming Processing Work

China

China