Wire HARNESS Injection Molding Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- HARNESS-3zR-20

- Payment Terms

- L/C

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Wiring Harness , Automotive Plastic Products

Apply a video call to the Supplier

i-SSAN Engineering

- Verified Certificate

-

12

| Product name | Wire HARNESS Injection Molding Machine | Certification | - |

|---|---|---|---|

| Category |

Wiring Harness

Automotive Plastic Products |

Ingredients | - |

| Keyword | automobile plastic parts , wire harness , grommet molding , harness molding | Unit Size | 1200.0 * 2500.0 * 1400.0 mm |

| Brand name | HARNESS-3zR-20 | Unit Weigh | 900 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

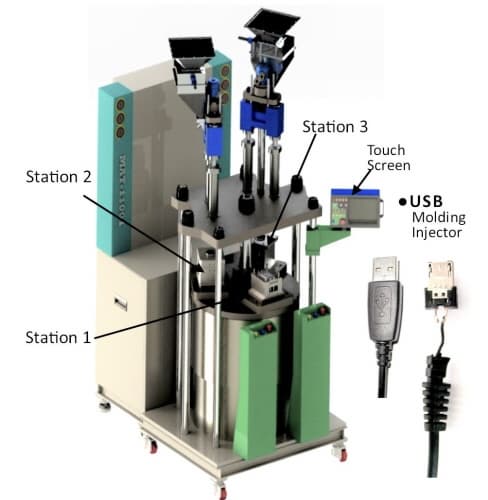

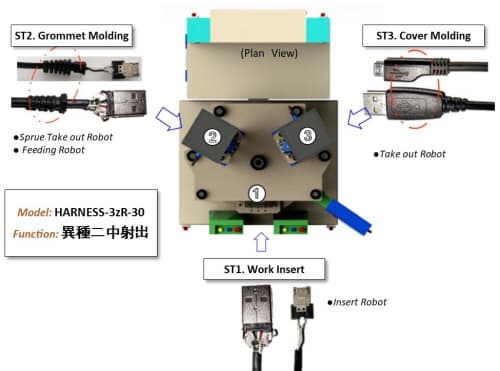

CONCEPT of Automated HARNESS Injection Molding machine

Special purpose injection molding system that has evolved to concentrate and integrate complex harness molding work in one place.

The general method is the first grommet injection molding and the second harness molding.

In this case, the equipment consists of three zones.

At this time, the harness injection machine model applied is HARNESS-3zR-20.

HARNESS-----------Initial Harness Machine

3zR -----------Mold (or tool) number of components 3

Turntable type Vertical Injection Molding Machine

20 ------------Injection capacity 20CC

Each zone is placed with a corresponding insert mold. At this time, the insert mold will use an automated functional mold, such as automatic replacement of the core and reverse opening and closing sequence.

If it is difficult to maintain the insert of the work, add a pre-molding process.

Pre-Molding may occur once, twice, or three times depending on the insert structure and formation of the product.

At this time, the applied model is HARNESS -3zR-20-2X.

Configuration of Automatic Harness Injection Molding System

Cable takeout station,

Cable cutting,

Cable stripping,

Soldering equipment,

Micro press and crimping machine,

Auto parts feeder with insert robot,

Insert mold,

Turntable type multi-molding workstation with control set,

Single process injection molding machine,

Jigs and fixtures,

CNC-Nz-xx grommet injection molding machine.

Sprue runner takeaway robot,

Vision inspection modulearness

Injection molding machine for Hanas HARANS-NzR-XX

After all, the purpose of the harness converter is to build an ultra-compact micro plant that utilizes automatic control technology based on the space where the harness manufacturing process is extremely concentrated.

Considering the reality of the current harness manufacturing plant, which is very complicated and has a long worker's circulation, which is difficult to overcome the limitations of management, it is a very innovative production system.

JUNO S&P inc, aims to minimize production system overload and idle time unevenness by intensively managing processes dynamically and organically.

These are called DrPs.

DrPs: Dynamic Revolution of Production System

General SPECIFICATION

Harness Injector, 2 zone, 3 zone, 4 zone | ||||||||||

| HARNESS 2zR- | HARNESS 3zR- | HARNESS 4zR- | |||||||

10 | 20 | 30 | 10 | 20 | 30 | 5 | 10 | 15 | ||

|

|

|

|

|

|

|

|

| ||

Injection Volume | CC | 10 | 20 | 30 | 10 | 20 | 30 | 5 | 10 | 15 |

Utility |

| Hydraulic | ||||||||

Mold Type |

| Center Sprue , Functional | ||||||||

No. of Molds / Jig |

| 1/1 | 1/1 | 1/1 | 2/1 | 2/1 | 2/1 | 3/1 | 3/1 | 3/1 |

Min, Mold Height | mm | 120 |

| 150 | 150 | 150 |

|

|

|

|

Min Mold Size | mm | 80x80 |

| 80x80 | 150x150 | 150x150 |

|

|

|

|

Max Mold Size | mm | 110x110 |

| 130x130 | 200x200 | 200x200 |

|

|

|

|

Machine Size (WXD) | m |

|

|

| 1x1.2 | 1x1.4 | 1x1.5 |

|

|

|

Machine Weight | Kg |

|

|

|

|

|

|

|

|

|

Control |

| Touch Screen Interface | ||||||||

Power |

| 380VAC, 3Ph | ||||||||

Installation |

| Portable type, Caster Moving | ||||||||

Utility-imbedded |

| Temperature Controller of Mold | ||||||||

| Micro Chiller of Hopper | |||||||||

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C | Shipping time | Negotiable |

- President

- Minho Kim

- Address

- 356-10, Hwaseong-si, Gyeonggi-do, Korea

- Product Category

- Medical Consumables,Molds,Other Rubber Products,Plastic & Rubber Machinery Parts,Plastic Product Making Machinery

- Year Established

- 2018

- No. of Total Employees

- 1-50

- Company introduction

-

Business Scope

▷ Mold making

▷ Injection & Extrusion equipments

▷ Automation

▷ R&D

▷ Plant, System Engineering

Business Items

Machineries, Tools, Special Equipments that we make;

① Plastic Injection Molding machines

② LSR Injection molding Machines

③ PIM machineries (with related material handling equipments)

④ CNC Injection molding machines ( Full Automation )

⑤ Special Injection molding machine (LED, Slipring, Relay Connector)

⑥ Extruder,

⑦ Automatic Injecton Molding system

⑧ Specilized/Customized for Ultra Micro & Precision Injection molding sysm.

(LSR, Artificial Eyeball)

Software Service:

Design & Developing manufacturing process of New Materials related

with Injection, extrusion and press technologies.

① New materials of Polymers

② Nano- Powders (Metal, Ceramic),

③ Liquid Silicon Rubber(LSR)

Engineering consulting:

① Part design & Modeling (2D, 3D),

② Process Developing,

③ Plant Engineering.,

Mold Making Service(Specialized)

① Plastic Mold,

② PIM, PICM, PIM2K, PICM2K (Functional Mold for PIM)

③ LSR Mold

Special System (Micro Plant)

① Automatic LED module production system,

② Automatic Relay connector insert molding system,

③ Surgical Anchor (Screw) production system (Biodegradable resign),

④ Artificial Eyeball parts (LSR),

⑤ CNC Injection molding machine.

Special Producing items

① Medical Comsumables : Sutute Anchor (Peek & Biodegradable materials)

② Artificial Organ : Artificial blood vessel (Teflon)

: Artificial Eyeball (LSR)

③ Menstrual Cup (LSR)

④ Industrial Parts

⑤ Cushiion seat of Egg tray(LSR)

- Main Markets

-

South Korea

South Korea

- Factory Information

-

I-SSAN ENGINEERING

- Main Product