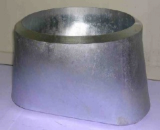

High Pressure Coolant System

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

Apply a video call to the Supplier

Kemtech

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | High Pressure Coolant System | Certification | - |

|---|---|---|---|

| Category | Refrigeration & Heat Exchange Machinery | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

I. Necessity of High Pressure Coolant

Recent interest on high pressure fluid grew as machine tools tend to become high speed and high precision.

Low pressure (below 14kgf/cm2) cutting fluid is blocked by the vapor barriers created by machine tool..s cutting speed. It loses cutting fluid function before it enters the cutting zone because of evaporation.

On the other hand, high pressure (over 20kgf/cm2) cutting fluid can reach the cutting zone to achieve the following :

- Smooth lubrication and cooling effect

- Improvement in cutting capability

- Improvement in tool lifetime by removing the phenomenon of chip re-cutting

- Improvement in cutting surface roughness

- Smooth chip removal effect

- Deburring effect

- Smooth cutting and cutting capability improvement in special processes such as deep hole processing and difficult-to-cut material processing

In case 70kgf/cm2 high pressure cutting fluid is used in the cutting of difficult-to-cut materials, the tool manufacturer test shows the following results compared with the use of common cutting fluid.

- 20% reduction in cycle time because of an improvement in cutting speed and feed

- 50% improvement in tool lifetime

II. Hole Processing (Drilling , Boring and etc.)

| Low Pressure Cutting Fluid / Flood Coolant | |

|

|

| High Pressure Cutting Fluid / Through Tool Coolant | |

|

|

III. Turning

| High Pressure Coolant | |

|

|

IV. Application

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Noh, Kook-jin

- Address

- #810, UKIC, 812-1, Hyomoon-Dong, Buk-Gu, Ulsan, Korea

- Product Category

- Other Generators,Other Machinery & Industry Equipment

- Company introduction

-

Kemtech has focused its best endeavors in the machine tool field with high class technology in the chiller unit, high pressure coolant system and filtering

area for the automotive industry. Our accomplishment have been achieved by

listening to our customers needs and fulfilling their requirements, and offering our insights. Kemtech will continue to do its utmost by carrying out a policy of superior quality while reducing cost every step of the way. Product by Kemtech will always be serviced speedily and efficiently so our customers can be market leaders in their own fields. At Kemtech, all employee, from the president to line workers, will be impelled to improve in all areas from understanding the customers better and seeking new opportunities to looking at how we are doing thing today so to be better at it tomorrow. With this as our corporate foundation, we will move onto the world stage with strength and joy.

- Factory Information

-

Kemtech

- Main Product

Related Products

CENTRIFUGAL WATER CHILLER

High-Temperature Dehumidifier for Garment Industry

SAMJIN Hydroheat boiler energy saving than heat pump

Platelet Agitator Plasma thawer

SWAGE NOZZLE