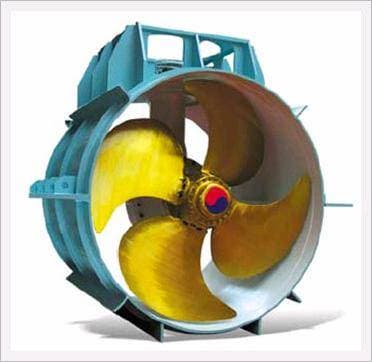

Cp Fp Propeller

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Vehicle Accessories

Apply a video call to the Supplier

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | Cp Fp Propeller | Certification | - |

|---|---|---|---|

| Category | Other Vehicle Accessories | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Features

Hyundai Thruster can be fitted to a wide range of vessels operating in all over the world. The tunnel thruster is designed for giving max. side thrust force to the ship in maneuvering condition.

Thrust system normally consists of the thruster unit with tunnel, hydraulic equipment, remote controller and prime mover.

Long service life and easy maintenance are key factors in the design and development of Hyundai Thruster.

Advantages

- Compact Design

- Powerful Thrust

- Low Noise, Low Vibration

- Well-balanced Performance (port / starboard)

- Superior Quality

- Easy Installation

- Easy Operation

- Easy Maintenance

- Reliable System Interface Control

- Rapid Technical Service

- Quality-oriented Feedback Activity

System Configuration

Hyundai Thruster system consists of the thruster unit with tunnel, hydraulic equipment for pitch control, gravity tank, remote controller, feedback device and electrical driver with starter. Operating the pitch control dial mounted on the remote controller in the wheel house or wing side actuates the solenoid valve inside the hyd. Pump unit, then pressurized oil move the cross head

(piston) directly.

Actuating forces of the piston is converted into torque by sliding shoe mechanism, changing the

pitch angle of the propeller blade accordingly. The stroke of the propeller is transmitted from the

cross head to the angle transmitter via chain. The angle transmitter converts mechanical stroke

into electrical feedback signal displayed on the control board.

Complete Thruster Package

Tunnel Instrallations

| Standard type | Tunnel extension type | Straight-cut tunnel extension type |

|

|

|

Remote Controller

Functions

- Blade Angle Pitch Control (Auto / Manual Mode)

In automatic mode, the blade pitch can be controlled by the remote control dial at any

desired position. In case, the failure of auto pitch control (emergency situation), it can be manually operated by maneuvering the push button (PORT or STARBOARD). - Overload Protection (OLP)

When current value of the main motor exceeds the OLP setting value at the operation, this controller has multi-function not only to inform the user of the status as like "Motor Full Load" but also to reduce the load automatically to the OLP setting level. - Remote control of thruster and Aux. machineries

Thruster motor and aux. machineries (Fan & Hyd. oil pump) can be remotely controlled by

pushing the buttons on the controller. - System Alarm & Status Display

All necessary signal (alarm & status) from local side can be displayed on the controller for user`s notice.

Advantage

- More compact size

Installation space can be saved because input / output boards, CPU board and other control boards are incorporated to one (1) board micom. - Variable load display

Load display can be selected either motor current value or percentage of load calculated in the soft-program. - System error display

For user`s convenience, each system error can be identified with an error code on load

display window. - Storage of thruster operating data

For optimum operating of thruster, the recent operating data which have been stored to be

checked in order to get a desired data. - Main Control Panel (mounted on the bridge console)

- 8 bit micro processor (processing speed : over 10 MIPS)

- Digital Inputs (18 channels) / Analog Inputs (4 channels)

- Digital Outputs (16 channels) / Analog Outputs (2 channels)

- Dimmer control board (including back light function)

- Pitch control dial (21 steps, percentage display)

- Control station selection (Wheel house / Wing)

- Pitch control mode (Auto / Manual)

- Operation mode (Control source on / Stop / Aux. Run / Thruster request / Thruster run)

- Alarm / Status Display

- Emergency Control

- Aux. Control Panel (located on the port and st`bd wing side)

This controller has the same function as main controller excluding alarm / status display function.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |