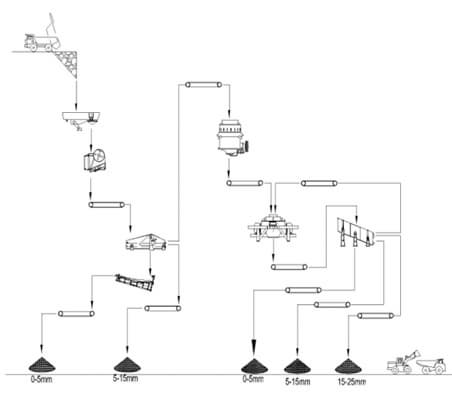

Granite production line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- granite cone crusher, granite crushing plant, granite impact crusher, granite stone crushing plant

- Category

- Mining Machinery

Apply a video call to the Supplier

Zhengzhou Zoonyee Mining Machinery co,.Ltd

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

11

| Product name | Granite production line | Certification | - |

|---|---|---|---|

| Category | Mining Machinery | Ingredients | - |

| Keyword | granite cone crusher , granite crushing plant , granite impact crusher , granite stone crushing plant | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Zhengzhou Zoonyee Mining Machinery co,.Ltd

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

-

11

- President

- zhangsheng

- Address

- Zhengzhou Xingyang Three Mile Zhuang Industrial Park

- Product Category

- Mining Machinery

- Company introduction

-

Zhengzhou Zoonyee Mining Machinery Co., Ltd (former State-owned Henan Mining Machienry Plant) is engaged in research & development, production and sale of the crushing and screening equipment, sand making and washing equipment, the complete set beneficiation equipment, urban construction waste mobile crushing and screening system. Zoonyee insists on implementing the development strategy of high class talented person, high technology, and high quality. According to the situation of domestic and foreign market, Zoonye designs and develops "Mobile construction waste recycling system", and in a first-line had a successful application. We follow the viewpoint of innovation, development and hardworking, advance with the times, establishing the close contact with machinery research institute in Zhengzhou, Luoyang, Beijing, Changsha, Changchun and so on. We found engineering technology research center, and a large of skilled person come together here. We train a high efficiency worker team, and build a first-class modern production, monitoring base and sales network covering the whole country. We provide convenient and thoughtful service for all users. Zoonyee people insist on the management idea of quality first and service first, and Our products have been distributed to all the provinces, autonomous regions and municipalities in China as well as over 120 countries and regions in the world, such as Australia, Southeast Asia, Middle Asia, South Asia, South America, Middle East, east European, and Africa, etc. Our sand and stone crushing plant is the specified products for China railway group and many domestic large-scale construction unit. The cornerstone to our success is quality, a commitment to innovation, and customer satisfaction. We will conduct ourselves ethically and in a professional manner, treating all people with dignity and respect in order to promote a team environment, which will allow us to recognize and respond to the ever-changing market place in the end.

- Main Product

_2.png)