Rolls

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- India

- Brand name

- Adamite Rolls

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- rolls, adamite rolls

- Category

- Cast & Forged

Apply a video call to the Supplier

Kisco castings india Ltd

- Verified Certificate

-

8

| Product name | Rolls | Certification | - |

|---|---|---|---|

| Category | Cast & Forged | Ingredients | - |

| Keyword | rolls , adamite rolls | Unit Size | - |

| Brand name | Adamite Rolls | Unit Weigh | - |

| origin | India | Stock | - |

| Supply type | - | HS code | - |

Product Information

Rolls in different grades and sizes ranging from 8" to 26" for rolling mills

5.1 Adamite Rolls C Mn Si S Max P Max Cr Mo Ni V Max Shore Hardness

1.35-1.45 .55-.70 .45-.60 .035 .035 .75-1.05 .25-.35 1.00-1.25 .10 40°-45°

1.4-1.6 .60-.75 .50-.65 .035 .035 .8-1.1 .25-.35 1.00-1.25 .10 45°-50°

1.6-1.9 .65-.85 .60-.75 .035 .035; 1.1-1.4 .35-.45 .35-.45 .10 50°-55°

and traces of Boron, Zirconium and Niobium

5.2 S.G Iron (Pearlitic) Rolls Grade 1 and Grade2 C Mn Si S Max P Max Cr Mo Ni V Max Shore Hardness

3.1-3.6 .40-.65 1.45-1.7 .02 .05 .40-.65 .40-.80 1.6-2.0 .10 50°-64°

5.3 S.G Iron (Accicular) Rolls Grade 1 and Grade 2 C Mn Si S Max P Max Cr Mo Ni V Max Shore Hardness

3.1-3.6 .40-.60 1.4-1.7 .02 .05 .40-.65 .60-1.0 2.0-2.6 .10 58°-70°

3.1-3.6 .40-.60 1.4-1.7 .02 .05 .40-.65 .60-1.0 3.0-3.6 .10 60°-75°

COMPOSITION OF GRADES: 'Inquire composition'

Grade C Mn Si S(max) P(max) Cr Ni Mo

EN 1A .07-.15 .80-1.20 .10 Max .20-.30 .070 - - -

EN 8 .35-.45 .6-1.0 .10-.35 .050 .050 - - -

EN 9 .50-.60 .50-.80 .05-.35 .040 .040 - - -

EN 14A .15-.25 1.3-1.7 .10-.35 .060 .060 0.25max 0.4max -

EN 15B .35-.40 1.1-1.3 .05-.35 .060 .060 - - -

EN 16 .3-.4 1.3-1.8 .10-.35 .05 .05 - - 0.2-0.35

EN 18 .35-.45 .60-.95 .10-.35 .040 .040 85-1.15 - -

EN 19 .35-.45 .50-80 .10-.35 .040 .040 90-1.40 - .20-.40

SAE4340 / EN 24 35-.45 .45-.70 .10-.35 .040 .040 .90-1.40 1.3-1.8 .20-.35

EN 25 .27-.35 .50-.70 .10-.35 .040 .040 .50-.80 2.3-2.8 .40-.70

EN 30B .26-.34 .40-.60 .10-.35 .040 .040 1.1-1.4 3.9-4.3 0.2-0.4

EN 31 .90-1.20 .30-.75 .10-.3.5 .040 .040 1.0-1.6 - -

EN 36C .12-.18 .30-.60 .10.35 .040 .040 .60-1.1 3.0-3.75 .10-.25

EN 39B .12-.18 .50 max .10-.35 .030 .030 1.0-1.40 3.80-4.50 .15-.35

EN 41B* .35-.45 .6S max .10-.45 .040 .040 1.5-1.8 .40 max. .10-.25

EN 42 .70-.85 .55-.75 .10-.40 .040 .040 - - -

EN 44 .90-1.20 .45-.70 .15-.35 .040 .040 - - -

EN 45A .55-.65 .70-1.0 1.7-2.0 .040 .040 - - -

60Si7 .56-.65 .70-1.00 1.5-2.0 .040 .040 - - -

EN 47 .45-.55 .50-.80 .50 max .040 .040 .80-1.2 - -

EN 351 .20 max .60-1.0 .35 max .040 .040 .40-.80 .60-1.0 .1 max

EN 353 .20 max .5-1.0 .35 max .040 .040 .75-1.25 1.0-1.5 .08-.15

EN 354 .20 max .50-1.0 .35 max .040 .040 .75-1.25 1.5-2.0 .10-.20

EN 355 .20 max .40-.70 .35 max .030 .030 1.40-1.70 1.8-2.2 .15-.25

31CrV3* .29-.33 .40-.60 .35 max .040 .040 .40-.70 - -

16MnCr5 .14-.19 1.0-1.3 .15-.40 .035 .035 .80-1.1 - -

20MnCr5 .17-.22 1.1-1.4 .10-.35 .035 .035 1.0-1.3 - -

SAE 1025 .22-.28 .30-.60 .15-.30 .040 .040 - - -

SAE 1541H .35-.45 1.25-1.75 .15-.30 .040 .040 - - -

SAE 4130 .28-.33 .40-.60 .15-.30 .040 .035 .80-1.1 - .15-.25

SAE 4135 .33-.38 .60-1.0 .15-.30 .040 .030 .75-1.2 - .15-.25

SAE 4140 .38-.43 .75-1.0 .20-.35 .035 .035 .80-1.1 - .15-.25

SAE 4145 .43-.48 .75-1.0 .15-.30 .035 .035 .80-1.1 - .15-.25

SAE 4145H .42-.49 .65-1.2 .15-.30 .035 .035 .75-1.2 - .15-.25

SAE 8620 .18-.23 .70-.90 .20-.35 .040 .040 .40-.60 .40-.70 .I 5-.25

SAE 8640 .37-.44 .70-1.05 .15-.30 .040 .040 .35-.65 .35-.75 .15-.25

SAE 52100 .95-1.1 .25-.40 .20-.35 .025 .025 1.3-1.6 - -

ASTM 105 .20-.25 .90-1.0 .15-.35 .040 .040 - - -

ASTM 201 .18 max 1.1-1.3 .05-.35 .040 .040 - - -

Chisel Steel .22-.28 .75-.85 .15-.35 .040 .040 1.2-1.3 .35-.40 .90-1.2

M 2* .78-.88 .20-.40 .20-.40 .025 .025 3.75-4.5 - 4.5-5.5

D 2* 1.4 -1.6 .20-.50 .10-.80 .035 .035 11-13 .30 1.0

D 3 2.0-2.3 .25-.50 .35 max .035 .035 11-12 .30 -

H 11* .30-.40 .25-.50 .80-1.2 .035 .035 4.7-5.25 .30 1.2-1.6

H 13* .30-.40 .20-.50 .80-1.2 .035 .035 4.5-5.5 .30 1.2-1.7

F 5 .15max .30-.60 .50max .030 .030 4.0-6.0 - .44-.65

F 9 .15max .30-.60 .5-1.0 .030 .030 8-10 - 0.9-1.1

F 11 .10-.15 .30-.80 .5-1.0 .035 .035 1.0-1.5 - .44-.65

F 22 .15max .30-.60 .50max .035 .035 2.0-2.5 - 0.87-1.13

*EN 41B - (Al - .90-1.20)*31CrV3 - ( V - .07-.12)*M 2 - (V - 1.6-2.2, W - 5.5-6.5)*D 2 - (V - 0.5-1.1)*H 11 - (V - 0.30- 0.60)*H 13 - (V - 0.80 - 1.2)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Raghav Goel

- Address

- http://www.kisco.in

- Product Category

- Cast & Forged,Ingots & Ore,Metal Casting Machinery,Steel

- Year Established

- 1999

- No. of Total Employees

- 501-1000

- Company introduction

-

Incorporated in 1992, Kisco Castings' commitment to strive for quality has developed it into a steel house for customers. Equipped with most modern technology and efficiency, educated and motivated workforce, it has developed consistent quality products that have time and again exceeded the expectation of its customers. Started from an opportunity in the small town in North India called Khanna, Kisco is abbreviated as Khanna Iron and Steel Corporation.

Kisco takes necessary care in coordinating and streamlining its production cycle to ensure customer satisfaction by timely execution of its orders. With its never ending quest for long term customer relationships, pre and post sales technical support has become an integral part of its system, which includes services like material selection, economic feasibility analysis and process engineering. Apart from the systems and facilities, dynamic approach of its valuable customers and employees is the key to the success of the company.

After forging strong foundation in steel, Kisco has demonstrated its mettle again by taking up the task of establishing a healthy foundation. Basic Healthcare Products, another manufacturing company, is established with the vision to maximize product values for patients and become a leading medical device company. Basic Healthcare Products is involved in researching and developing orthopaedic implants based on ceramic and metal processing technology. It has setup India's first Indian-FDA approved orthopaedic implant manufacturing facility in India. The facility is equipped with state-of-the art machinery and equipment in both machine shop and ceramic processing facility. The facility is also an ISO Class V facility to ensure the highest level of quality of its products that are supplied in the sterile form.

The highest quality is achieved at Kisco with the help of strong R&D support and stringent quality control norms strictly adhering to ISO 9001:2008 standards. Kisco Castings recently went multi-national with the launch of its new venture in US under the name Kisco Global LLC. Kisco Global LLC is the US subsidiary that procures excellent quality steel scrap for Kisco Castings and does sales and marketing for its range of products. Kisco always welcomes business opportunities for join collaboration of technology in casted rolls, castings, forgings among others. With the launch of Kisco Global LLC, Kisco Castings (India) Limited now has better control on the quality of steel.

- Main Markets

-

China

China

Denmark

Denmark

Finland

Finland

France

France

Hong Kong(China)

Hong Kong(China)

Hungary

Hungary

India

India

Ireland

Ireland

Israel

Israel

U.A.E.

U.A.E.

- Main Product

Related Products

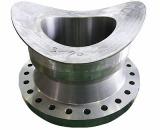

FORGED NOZZLE

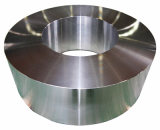

Forged Ring

ASTM A53 Steel Tubes and Tubulars

Water Hammer Cushion

Epoxy Mold Casting Plant for Cast Resin Transformer