Simulating Software for Continuous Casting Mold (CC-Mold)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Computer Software

Apply a video call to the Supplier

EXPRESSLAB

- Verified Certificate

-

8

| Product name | Simulating Software for Continuous Casting Mold (CC-Mold) | Certification | - |

|---|---|---|---|

| Category | Computer Software | Ingredients | - |

| Keyword | process design , quality estimation , continuous casting mold , transverse surface crack | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

Simulating Software for Continuous Casting Mold (CC-Mold)

│ DESCRIPTION │

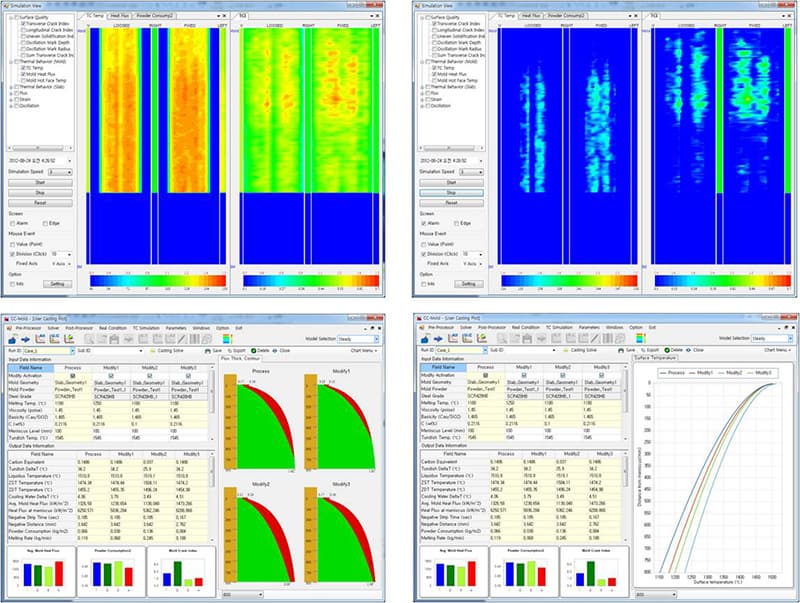

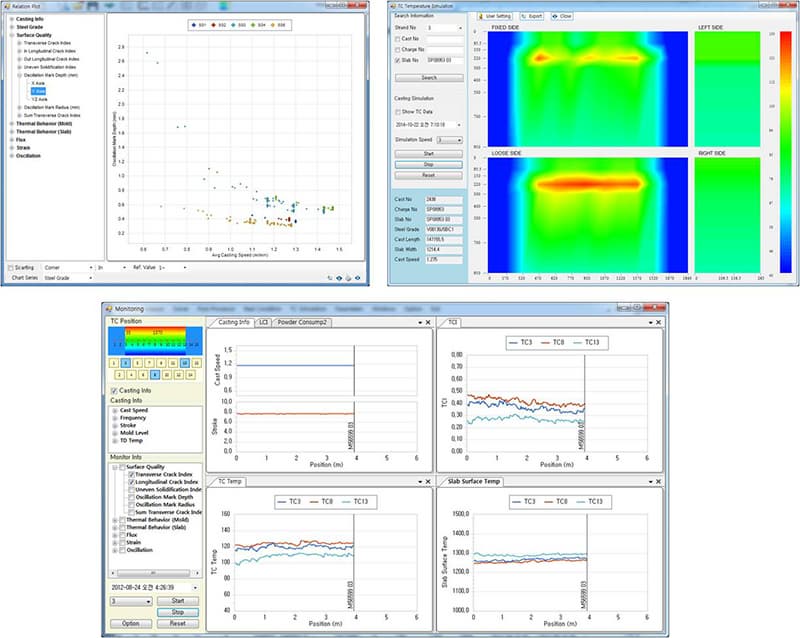

CC-MOLD is the professional tool developed for the process evaluation and optimization of continuous casting mold.

On/Off-line system based on real data enables realistic and accurate simulation of continuous-casting process and defect evaluation of strands in mold.

Its flexible and powerful graphical user interface makes preparation of input data and examination of result data easy to accomplish.

│ FEATURES │

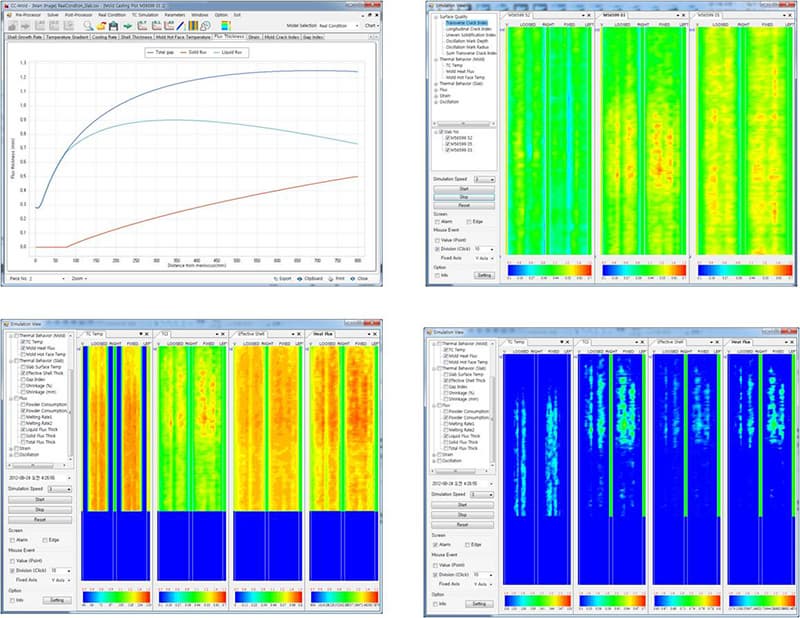

* Compact Mold Module enables to predict the temperature/ solidification behaviors mold with unique and simple Model. This works in coordination with other modules.

* Transverse Crack Module enables to evaluate the transverse and network intergranular crack indexes in mold. Prediction of crack initiation is very important for suppressing cracks because once crack is initiated, it readily propagates.

*Longitudinal Crack Module enables to evaluate the longitudinal crack index in mold. Uneven solidification is evaluated using temperature of Cu plate measured with thermo-couple.

* Process Simulation Module enables to optimize process condition such as mold powder, oscillation pattern, cooling condition, etc. Set-up of casting condition for new steel grade can be established using function efficiently.

* Monitoring Module enables to visualize casting conditions non-real-time. User can see casting history and calculated results by graphs and contour maps for checking the main factor of abnormal casting results.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Lee Joodong

- Address

- 1006 Jeongja I'Park, 100 Baekhyeon-ro, Bundang-gu, Seongnam-si, Gyeonggi-do, Korea

- Product Category

- Computer Software

- Year Established

- 2002

- No. of Total Employees

- 1-50

- Company introduction

-

<span style="font-family:Geneva, Arial, Helvetica, sans-serif;font-size:12px;"> To be pioneer motivating and making blue ocean of solutions based on convergence of theory and know-how.

BUSINESS AREA

Developing Solutions for Analysis / Design and Tracking / Control of industrial Process

- Continuous casting of steel

- Continuous casting of AI alloy

- Cold rolling process

- Ingot casting process

- Electrochemical plating process

- Desing of gas pipeline

- Main Markets

-

China

China

India

India

- Main Product

Related Products

SmartDesigner, Fashion Textile CAD Software

Perfect Music Server Player – sMS-1000

CADWIN Nesting Ver.19

Tayo the Little Bus (Animation)

Art Odyssey (Animation)

South Korea

South Korea