UNIPRETEC, advanced ceramics expert, provides component and custom integrated packaging solutions for Aerospace, Medical, Power Generation & Distribution, Automotive, Process Control & Monitoring, Industrial Equipment, Electronic & Electrical.

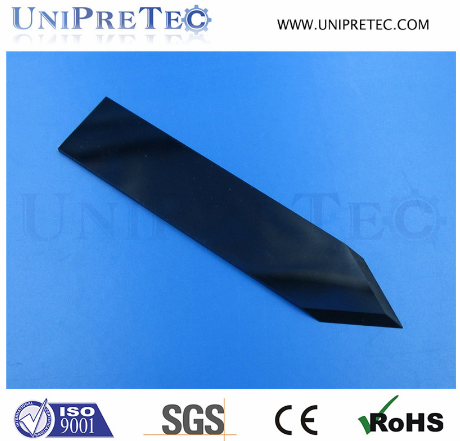

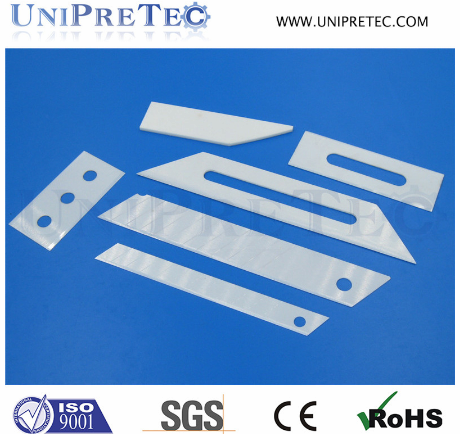

Our manufacturing of high-performance ceramic products is based on very high quantities in Alumina, Zirconia, Silicon Carbide, Silicon Nitride, Boron Nitride, Machinable Glass Ceramic and further special materials. Along with these materials, we offer several machining from which to choose such as cutting, drilling, sawing, turning, grinding, polishing etc.. Furthermore, our technologies and equipments allow us to provide various and flexible forming processes, like dry pressing, isostatic pressing, extrusion, injection moulding and slip casting.

China

China