1A1 Resin Bond Diamond Grinding Wheel for Carbide Tools

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Moresuperhard

- Payment Terms

- Others,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasive Tools

Apply a video call to the Supplier

Henan More Super Hard Products Co.,Ltd

- Verified Certificate

-

6

| Product name | 1A1 Resin Bond Diamond Grinding Wheel for Carbide Tools | Certification | - |

|---|---|---|---|

| Category | Abrasive Tools | Ingredients | - |

| Keyword | carbide tools , diamond grinding wheel , 1a1 grinding wheel , resin bond | Unit Size | - |

| Brand name | Moresuperhard | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

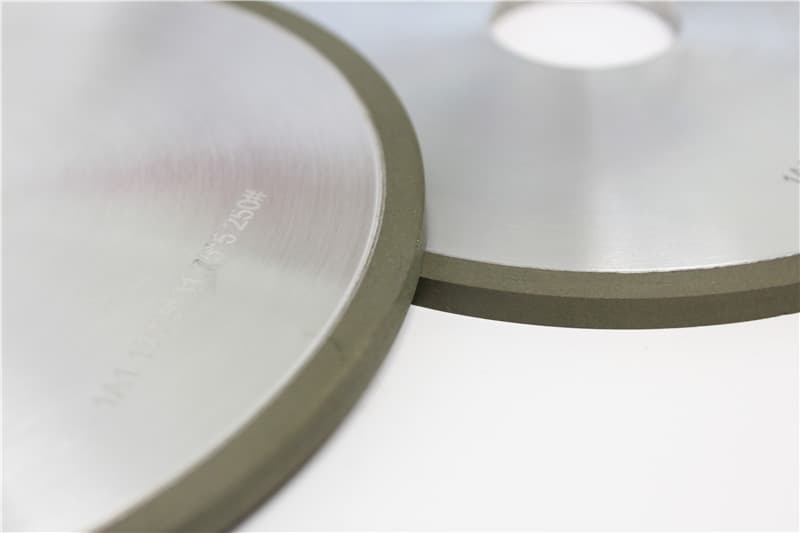

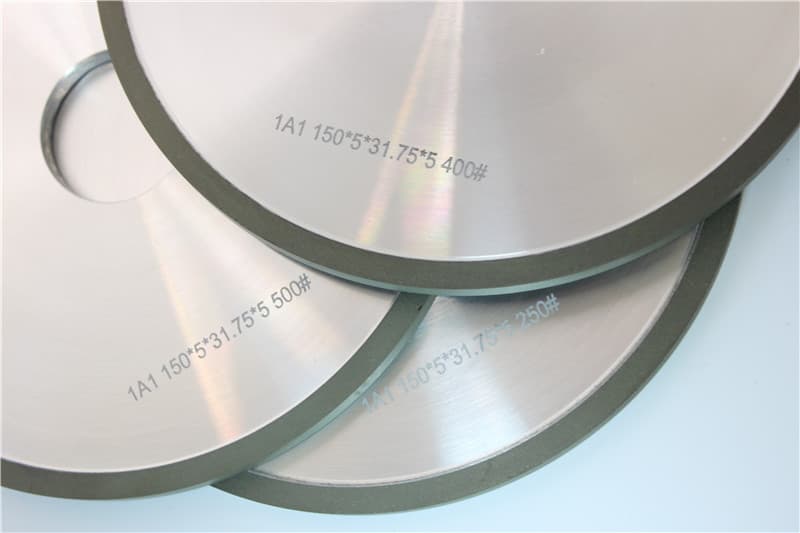

Name: Resin Bond Diamond Grinding Wheel for Carbide Tools

Introduction:Resin Bond Grinding Wheels Are The Most Commonly Used Super Abrasive Product Currently. Our Resin Diamond Wheel Is Suitable For Surface Grinding, OD Grinding, Centerless Grinding, Tool Grinding, Fine Grinding ,Double Disc Grinding And Slot Grinding Of Most Precision Workpieces.

Application :Resin Bond Diamond Grinding Wheel Is Mainly Used For Machining Tungsten Carbide Cutting Tools, Ceramic , Magnetic Materials, Silicon , Glass , Carbide Tools ,Quartz And Thermal Spraying Alloy ,Etc

Type: 1A1, 6A2, 14A1, 3A1, 11V9, Etc

Features: Resin Bonded Diamond Wheels

1. High performance

2. Engineered to your operation

3. Cool cutting action

4. Guaranteed Consistency

5. Excellent for grinding carbide inserts and other tools

Advantages Of Resin Diamond Grinding Wheel:

* High Cutting Efficiency,Good Self-Sharpening, Less Blocking,Reducing The Grinding Burn Occurs When The Phenomenon Of Work

* Good Flexibility Will Help To Improve The Surface Roughness, Mainly Used For Rough Grinding, Semi-Fine Grinding, Polishing And Other Processes

* Compared To Conventional Silicon Carbide , Resin Diamond Wheel Has Good Material Removal Rates, Longer Wheel Life And Lower Grinding Costs

* Resin Bond Diamond Wheels Generally Remove Material Up To Ten Times Faster Than Metal Bond Wheels

Feature | Sharp, wear-resisting, polishing effect is good, stable quality, good diamond |

Machine | Straight edge machine, beveling machine, bilateral machine, numerical control machine, Sunnen |

Market | Germany, Italy, India, Pakistan, Iran, United Kingdom, Belgium, Australia, Turkey, U.A.E, South Africa, Poland, Japan, Tai wan, The United States, Canada |

Certification | ISO9001:2000 Certificate |

Outer Diameter | 25-750mm |

Grit number | 45-426 |

Specifications Of Resin Bond Diamond Grinding Wheel For Thermal Spraying:

Diameter (Mm) | Diameter (Inch) | H (Mm) | T (Mm) | X (Mm) |

25 | 1 Inch | 6 | 12 | 6 |

30 | - | 12 | 6 | - |

40 | - | 12 | 6 | - |

50 | 2 Inch | 6 | 12 | 6 |

100 | 4 Inch | 12 | 12 | 10 |

150 | 6 Inch | 12 | 25 | 10 |

300 | 12 Inch | - | 25 | 10 |

400 | 16 Inch | 127 | 25, 50 | 10, 25 |

500 | 20 Inch | 127, 203.2 | 25, 50 | 10, 25 |

600 | 24 Inch | 254 | 25, 50 | 10, 16, 25 |

750 | 30 Inch | 304.8 | 50 | 10 |

914.4 | 36 Inch | 304.8 | 25, 50 | 10, 25 |

1100 | 43 Inch | 304.8 | 50 | 10 |

Ceramic diamond cutter grinding wheel is mainly used for PCD, CVD, PCBN, carbide, ceramic knives and other cutting tools milling | ||||

TYPE | Diameter | HIGHT | Hole | WIDTH |

6A2 | 100 | 40 | 20,32,40 | 5-15 |

6A2 | 125 | 40 | 32,40 | 5-15 |

6A2 | 150 | 40 | 32,40 | 5-15 |

11A2,12A2 | 100 | 40 | 20,32,40 | 5,10 |

11A2,12A2 | 125 | 40 | 32,40 | 5-15 |

11A2,12A2 | 150 | 40 | 32,40 | 3,5,10 |

|

|

|

|

|

Ceramic diamond diamond grinding wheel used natural diamond grinding polishing | ||||

1A1 | 80 | 10 | 32 | 8,10 |

150 | 10 | 32 | 10 | |

155 | 10 | 32 | 10 | |

160 | 10 | 32 | 10,12 | |

170 | 10 | 32 | 10,12,14 | |

175 | 10 | 32 | 10 | |

220 | 10 | 32 | 20 | |

14A1 | 170 | 10 | 32 | 10,12,14 |

175 | 10 | 32 | 10.15 | |

1, high grinding efficiency; | ||||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Others,T/T,Western Union | Shipping time | Negotiable |

- President

- Joe

- Address

- B906,Wanda Plaza, Zhongyuan Road, Zhengzhou, Henan, China

- Product Category

- Other Machinery Parts

- Year Established

- 2014

- Company introduction

-

"Henan More Super Hard Products Co.,Ltd" is specialized in manufacturing and marketing of diamond & CBN tools.

- Main Product

Related Products

_2.png)

Xonite Dendroid Brush(cleaning)

Polishing Film : XPS-P3

Engineered Stone Polishing Pad

Convex Polishing Pad for curved counter tops

Sun Turbo Cutter

China

China