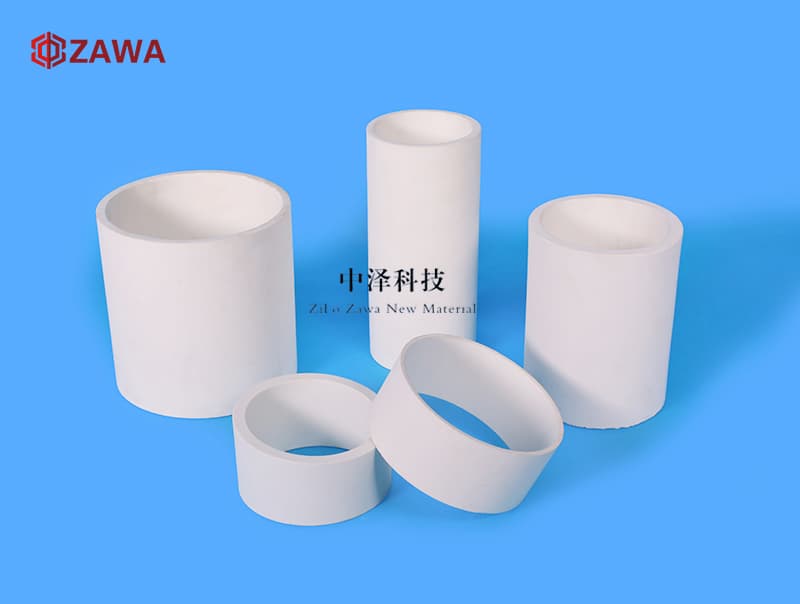

Wear-Resistant Alumina Ceramic Tube

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- zawa

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- chemical ceramic fillers, high temperature resistant alumina filling bead, 99% alumina filler, ceramic filling gear

- Category

- Oxide

Apply a video call to the Supplier

Zibo Zawa New Material Co., Ltd

- Verified Certificate

-

6

| Product name | Wear-Resistant Alumina Ceramic Tube | Certification | - |

|---|---|---|---|

| Category | Oxide | Ingredients | - |

| Keyword | chemical ceramic fillers , high temperature resistant alumina filling bead , 99% alumina filler , ceramic filling gear | Unit Size | - |

| Brand name | zawa | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Product | 92 | 95 |

Al2O3% | ≥92 | ≥95 |

Fe2O3% | ≤0.2 | ≤0.15 |

Mohs' hardness | 8 | 9 |

Water Absorption (%) | ≤0.02 | |

Bulk Density(g/cm3) | ≥3.60 | ≥3.65 |

Abrasion(%) | ≤0.02 | |

Pipe linings of alumina ceramic cylinders have the following advantages:

1.Cold isostatic pressing method makes long lifetime.

2.Maintenance-free operation makes no operation interruption and production losses.

3.Good corrosion resistance to strong sour and alkali

4.Smooth surface to achieve good flow-ability and to avoid plugs.

Application:

1. Fly-ash pipework lined with alumina ceramic tubes

2. Pulverized coal pipework lined with alumina ceramic pipes

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Joanna

- Address

- zbzawa@163.com

- Product Category

- Oxide

- Year Established

- 2018

- No. of Total Employees

- 101-500

- Company introduction

-

<p>ceramic filling ballZibo Zawa New Material Co., Ltd located in Zibo high-tech development zone inShandong province. It is a professional manufacturer and exporter of alumina ceramicballs, alumina ceramic tiles, alumina chemical filling balls, alumina rubber composite platesand zirconium aluminum composite materials. The main products include filling balls,grinding balls, alumina plates, wear-resistant tiles, tubes and various special wear-resistantparts, etc. The annual output reaches 20,000 tons.Zawa company introduced the most advanced full set of production equipments, includingspray granulators, automatic isostatic pressing machines, two-way long-stroke hydraulicbrick presses, 1700°C high-temperature tunnel kilns, shuttle kilns and other sinteringfurnaces. Meanwhile, our laboratory configured with advanced testing equipments, such asthe particle size analyzers and density meters, to ensure the strict inspections during all theaspects of production and finished products, such as the particle size analyzers and densitymeters.The company's backbone employees all have more than twelve-year industrial ceramicproduction experience. While constantly absorbing high-level employees, we also makeregular training for employees at all levels to ensure that employees can perform andcontrol the industry technology standard during job. With the guide of scientificdevelopment and bold innovation, we produced a large batch of 99%-99.7% alumina fillingballs recently. With competitive prices and high quality, alumina balls created a huge valueto end users, intermediate users and agents and truly achieved a win-win situation forboth producers and users.Our products have been exported to Germany, Australia, the United States,India,Brazil,South Africa, Southeast Asia and other countries, providing high-end productsfor foreign customers in the industrial ceramic industry. Based on the principle oftechnological innovation, quality-first and excellent service, customers are welcome to ourcompany to negotiate alumina wear-resistant balls, filler balls, ceramic wear-resistantsheets, zirconium-aluminum composite materials and regenerators. As a professionalsupplier, we wish to create a better tomorrow with you together!

- Main Markets

-

U.S.A

U.S.A

- Main Product

Related Products

TITANIUM DIOXIDE RUTILE GRADE KR-1000

Crystal Sensor For Vacuum Coating

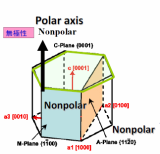

Sapphire wafer A-plane R-plane M-plane semi polar non polar

e-beam sources and evaporation materials (evaporation pellets, wire, pieces and others)

Rare earth oxide include CeO2, La2O3,Sc2O3

China

China