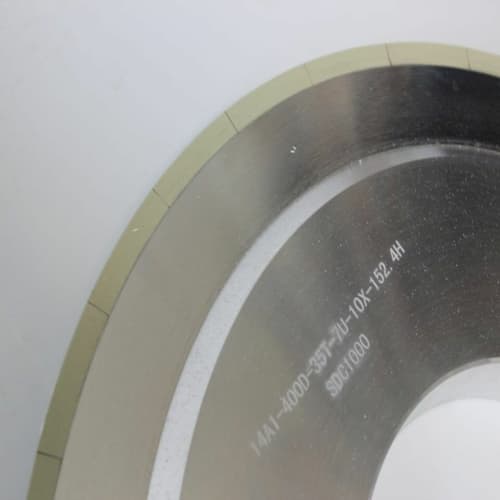

1A1 vitrified bond diamond grinding wheels

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Moresuperhard

- Payment Terms

- L/C,MoneyGram,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- ceramic diamond grinding wheel, ceramic bonded grinding wheel, diamond super-hard grinding wheel, high efficiency grinding wheel

- Category

- Other Machinery Parts

Apply a video call to the Supplier

Henan More Super Hard Products Co.,Ltd

- Verified Certificate

-

6

| Product name | 1A1 vitrified bond diamond grinding wheels | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | ceramic diamond grinding wheel , ceramic bonded grinding wheel , diamond super-hard grinding wheel , high efficiency grinding wheel | Unit Size | 100.0 * 20.0 * 100.0 mm |

| Brand name | Moresuperhard | Unit Weigh | 2 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Introduction of vitrified bond diamond grinding wheels

Vitrified bond diamond grinding wheels possess pretty high abrasive resistance, especially in polishing hard and brittle workpiece. It has many advantages like small grinding force, low operating temperature, high grinding precision, excellent workpiece's surface grinding, etc. Therefore, vitrified bond diamond grinding wheel will express the better advantages in the future. It is recognized as a high performance grinding wheel with the higher speed, higher efficiency, higher precision, lower abrading cost and lower pollution. Based on these superiorities, vitrified bond diamond bruting wheel is widely used in wafer, PDC, PDC, diamond cutter, CBN, cemented carbide, new engineering structural ceramic, diamond, jewel, crystal, rare earth materials and another hard-brittle materials' machining operation.

Applications of vitrified diamond wheels for PCD and PCBN tools :

PCD cutting tools, PCBN cutting tools, CVD tools, MCD tools, milling cutter, reamer, drill and regrinding, etc

Feature |

1:Name:vitrified bond diamond grinding wheels |

2:Type Code: 1A1, 3A1, 11A2, 14A1,1 6A1,6A2, 12A2, 12V2, 6A2T, 11V2, 9A1, 1A1R, |

3:Material: Diamond, CBN |

4:Size: D. 25-500mm; T. 5-40mm; H. 10-127mm. |

5:Line speed: 35~80 (M/S) |

6:Grit: 80#~5000# (D251-D1) |

7:Application Industry: Jewelry, Automobile, Aerospace, Oil drilling, Coal mining, Metal processing |

8:Certification: ISO 9001:2008 |

9:Diamond grit: #100, #150, #200, #300, #400, or upon your request |

10:Type: straight wheel, bowl-shaped wheel, cup-shaped wheel, dish- shaped wheel |

Product Feature introduction |

Advantages of vitrified diamond wheels for PCD and PCBN tools :

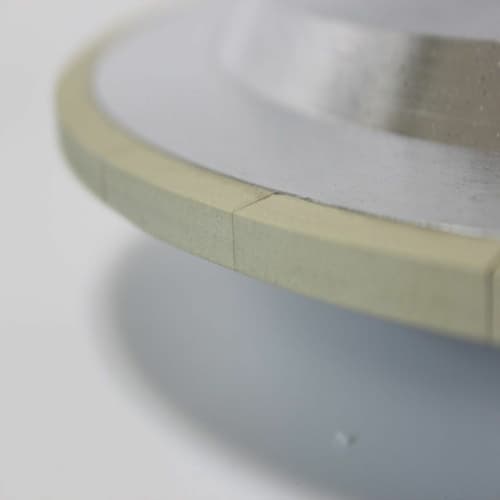

1.The porous structure of the abrasive improved diamond exposure and Can Prevent Vertical Streaks On Workpiece And Improve Surface Quality

2.Accurately control geometric tolerances to make a good abrasive layer

3. Good Self-Sharpening, High Grinding Efficiency,High Wear Resistance And Less Abrasive Grain Consumption

4.High Precision Workpiece. PCD Tools Can Reach High Efficiency , Good Surface Finish And Edge No Chipping

5. Vitrified Bond Wheels Offer Tool Life Greater Than 150 Times That Of A Resin Bond Wheel And Can Be Easily Trued And Dressed On The Machine

The advantages of diamond bruting wheels

1. Compared with resin bond wheel and metal bond wheel, vitrified diamond bruting wheel could process at least 2 to 3 times products at the same time.

2. not easy to jam and burn the workpiece, good self-sharpening, easy dressing and long life .

3.High abrasive resistance and abrasive wear is small

Product description of vitrified bond diamond grinding wheels

1.Vitrified bond diamond grinding wheel possess pretty high abrasive resistance, especially in polishing hard and brittle workpiece.

2.Vitrified bond diamond grinding wheel has many advantages like small grinding force, low operating temperature, high grinding precision, excellent workpiece's surface grinding, etc.

3. Vitrified bond diamond grinding wheel recognized as a high performance grinding wheel with the higher speed, higher efficiency, higher precision, lower abrading cost and lower pollution.

4.Vitrified bond diamond grinding wheel is widely used in wafer, PDC, PDC, diamond cutter, CBN, cemented carbide, new engineering structural ceramic, diamond, jewel, crystal, rare earth materials and another hard-brittle materials' machining operation.

Production process of ceramic diamond grinding wheel:

1. Mix: the binders and diamond powder are fully stirred and fused in a certain proportion

2. Weighing: weighing according to the volume, ring width and density of the grinding wheel required by the customer

3. Feeding: put mixed diamond powder and binding agent into the grinding tool

4: compression ring (let stand for a period of time to wait for molding)

5: back mould

6: the abrasive layer is air-dried

Cook for 10 hours at 7:670 degrees

8: cooling (prepare the matrix at the same time)

9. Fixed decoration of the whole

10: measure stationarity

product show

Shape code | diameter | high | aperture high | Ring width | Abrasive thickness |

1A1 | 80 | 10 | 32 | 8,10 | 5—30 |

150 | 10 | 32 | 10 | 5—30 | |

155 | 10 | 32 | 10 | 5—30 | |

160 | 10 | 32 | 10,12 | 5—30 | |

170 | 10 | 32 | 10,12,14 | 5—30 | |

175 | 10 | 32 | 10 | 5—30 | |

220 | 10 | 32 | 20 | 5—30 | |

14A1 | 170 | 10 | 32 | 10,12,14 | 5 |

175 | 10 | 32 | 10,15 | 5 | |

6A2 | 100 | 40 | 20,32,40 | 5,10,15 | 10 |

125 | 40 | 32,40 | 5,10,15 | 10 | |

150 | 40 | 32,40 | 5,10,15 | 10 | |

11A2,12A2 | 100 | 40 | 20,32,40, | 5,10 | 3—10 |

125 | 40 | 32,40 | 3,5,10 | 3—10 | |

150 | 40 | 32,40 | 3,5,10 | 3—10 |

carton box with foam box (Gift package is available)

Why choose our product

Our product’s advantages: 1.High grinding efficiency |

2.Wonderful edge quality |

3.Long service life |

4.High polishing efficiency |

5.Large Exports |

6.Considerable after-sell service |

7.Amazing performance |

8.Various types and sizes available |

9.Direct Factory Manufacturer |

10.Backing/substrate material: Aluminum |

11.Abrasive layer: diamond |

12.Bond: vitrified |

13.Excellent cutting edges |

14.Reduced cycle times |

15.Custom Engineered |

If you have any questions, please contact us

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,MoneyGram,Western Union | Shipping time | Negotiable |

- President

- Joe

- Address

- B906,Wanda Plaza,Zhongyuan Road,Zhengzhou,Henan,China

- Product Category

- Other Power Tools

- Year Established

- 2014

- No. of Total Employees

- 1-50

- Company introduction

-

<p>

Henan More Super Hard Products Co.,Ltd LTD is a professional production and sales of diamond and CBN tools high-tech enterprise, dedicated to provide customers with special custom or FEPA standard abrasives products, more than 800 customers benefit from us in product development, production and application of outstanding ability, satisfy the customer to us more efficient grinding and cutting, more precise and more experience

- Main Product

Related Products

180 degree rotation brushless servo XQ-S5650D

Vagcom 17.1.3 ATMEGA162 VCDS 17.1.3 China crack VAG 17.13 Fo

All in one POS SYSTEM

vacuum band-cylinder

EMI Shielding Metal Spring Gasket

China

China