CBN/Diamond grinding wheels,double disc grinding wheel

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasive Tools , Abrasives

Apply a video call to the Supplier

More super hard product company

- Verified Certificate

-

6

| Product name | CBN/Diamond grinding wheels,double disc grinding wheel | Certification | - |

|---|---|---|---|

| Category |

Abrasive Tools

Abrasives |

Ingredients | - |

| Keyword | cbn grinding wheel , diamond grinding wheels , double disc grinding wheel , doubsle disc | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

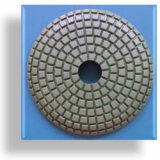

Double Disc Grinding in Automotive Parts Manufacturing

Grinding automotive three-pump parts series ceramic CBN grinding discs are suitable for flat grinding of automotive three-pump blades, rotors, stators, nozzles and other components.

Diameter: 380mm--1500mm

Aperture: 50mm--500mm

Base thickness: 50mm--100mm

Granularity: 80 mesh - 1500 mesh

Abrasive layer thickness: 5mm--10mm

Abrasive layer shape: cylindrical, hexagonal, fan-shaped.

Double-disc grinding wheel has long had a home in the automotive industry, where dedicated operations can take full advantage of its high productivity rates. Today, a number of advances allow double-disc grinders to meet requirements for improved performance in these traditional applications, and they also are opening the way to productive use in new applications. Capabilities are now available for easier machine operation, control flexibility, statistical process control (SPC), faster changeovers and setup, and applications on an expanded range of materials, including ceramics and graphite.

Double-disc grinding wheel Applicable equipment

Peter walter Japan koyo, Japan Fuji, Germany, Italy, Britain's m special import machine tools;Suitable for qinchuan development, Shanghai line diagram, hangzhou machine tool, such as domestic machine tool plant of xinxiang double end face grinding machine.

Supporting equipment: Xinxiang SKF, South Korea AM, Germany Pete Walter, UK Laimat and other domestic and foreign double-face grinder.

Double-disc grinding wheel Application

Ceramic diamond, CBN honing plateCeramic bond diamond millstone is mainly used for coarse grinding, fine grinding, fine grinding, grinding, polishing surface and inner hole grinding, grinding objects are: ceramics, gems, semiconductor materials, plane grinding blade, piston rings, bearing, etc, have the characteristics of long service life, low grinding cost, can greatly improve the efficiency of grinding, flatness, parallelism, processed products roughness completely satisfy the requirements of the customers.Grinding wheel specifications Ф 100 ~ Ф 1200 mm.Each set of grinding wheel processing parts number 500000 ~ 1500000, roughness: Ra0.05 microns to Ra0.2 microns, flatness 2 microns or less, ∥ 2 microns or less.Single plate size error between parts for 1 ~ 2 microns.

Double-disc grinding wheel features

1. High precision diamond grinding disc grinding and polishing once completed.

2. To shorten the processing time, in a short period of time to achieve high precision surface.

3. The original colour and lustre Bai Jinliang workpiece surface is metal.

4. For stainless steel plate, copper, aluminum, titanium alloy in the process of grinding, non-stick silk night, difficult to jam.

5. No scratches, no workpiece surface pitting.6. This product service life is long, reduce grinding disc wheel changed frequently.

CBN/Diamond grinding wheels - double disc grinding wheel

Double Disc Grinding in Automotive Parts Manufacturing

Grinding automotive three-pump parts series ceramic CBN grinding discs are suitable for flat grinding of automotive three-pump blades, rotors, stators, nozzles and other components.

Diameter: 380mm--1500mm

Aperture: 50mm--500mm

Base thickness: 50mm--100mm

Granularity: 80 mesh - 1500 mesh

Abrasive layer thickness: 5mm--10mm

Abrasive layer shape: cylindrical, hexagonal, fan-shaped.

Double-disc grinding wheel has long had a home in the automotive industry, where dedicated operations can take full advantage of its high productivity rates. Today, a number of advances allow double-disc grinders to meet requirements for improved performance in these traditional applications, and they also are opening the way to productive use in new applications. Capabilities are now available for easier machine operation, control flexibility, statistical process control (SPC), faster changeovers and setup, and applications on an expanded range of materials, including ceramics and graphite.

Double-disc grinding wheel Applicable equipment

Peter walter Japan koyo, Japan Fuji, Germany, Italy, Britain's m special import machine tools;Suitable for qinchuan development, Shanghai line diagram, hangzhou machine tool, such as domestic machine tool plant of xinxiang double end face grinding machine.

Supporting equipment: Xinxiang SKF, South Korea AM, Germany Pete Walter, UK Laimat and other domestic and foreign double-face grinder.

Double-disc grinding wheel Application

Ceramic diamond, CBN honing plateCeramic bond diamond millstone is mainly used for coarse grinding, fine grinding, fine grinding, grinding, polishing surface and inner hole grinding, grinding objects are: ceramics, gems, semiconductor materials, plane grinding blade, piston rings, bearing, etc, have the characteristics of long service life, low grinding cost, can greatly improve the efficiency of grinding, flatness, parallelism, processed products roughness completely satisfy the requirements of the customers.Grinding wheel specifications Ф 100 ~ Ф 1200 mm.Each set of grinding wheel processing parts number 500000 ~ 1500000, roughness: Ra0.05 microns to Ra0.2 microns, flatness 2 microns or less, ∥ 2 microns or less.Single plate size error between parts for 1 ~ 2 microns.

Double-disc grinding wheel features

1. High precision diamond grinding disc grinding and polishing once completed.

2. To shorten the processing time, in a short period of time to achieve high precision surface.

3. The original colour and lustre Bai Jinliang workpiece surface is metal.

4. For stainless steel plate, copper, aluminum, titanium alloy in the process of grinding, non-stick silk night, difficult to jam.

5. No scratches, no workpiece surface pitting.6. This product service life is long, reduce grinding disc wheel changed frequently.

Double Disc Grinding in Automotive Parts Manufacturing

Grinding automotive three-pump parts series ceramic CBN grinding discs are suitable for flat grinding of automotive three-pump blades, rotors, stators, nozzles and other components.

Diameter: 380mm--1500mm

Aperture: 50mm--500mm

Base thickness: 50mm--100mm

Granularity: 80 mesh - 1500 mesh

Abrasive layer thickness: 5mm--10mm

Abrasive layer shape: cylindrical, hexagonal, fan-shaped.

Double-disc grinding wheel has long had a home in the automotive industry, where dedicated operations can take full advantage of its high productivity rates. Today, a number of advances allow double-disc grinders to meet requirements for improved performance in these traditional applications, and they also are opening the way to productive use in new applications. Capabilities are now available for easier machine operation, control flexibility, statistical process control (SPC), faster changeovers and setup, and applications on an expanded range of materials, including ceramics and graphite.

Double-disc grinding wheel Applicable equipment

Peter walter Japan koyo, Japan Fuji, Germany, Italy, Britain's m special import machine tools;Suitable for qinchuan development, Shanghai line diagram, hangzhou machine tool, such as domestic machine tool plant of xinxiang double end face grinding machine.

Supporting equipment: Xinxiang SKF, South Korea AM, Germany Pete Walter, UK Laimat and other domestic and foreign double-face grinder.

Double-disc grinding wheel Application

Ceramic diamond, CBN honing plateCeramic bond diamond millstone is mainly used for coarse grinding, fine grinding, fine grinding, grinding, polishing surface and inner hole grinding, grinding objects are: ceramics, gems, semiconductor materials, plane grinding blade, piston rings, bearing, etc, have the characteristics of long service life, low grinding cost, can greatly improve the efficiency of grinding, flatness, parallelism, processed products roughness completely satisfy the requirements of the customers.Grinding wheel specifications Ф 100 ~ Ф 1200 mm.Each set of grinding wheel processing parts number 500000 ~ 1500000, roughness: Ra0.05 microns to Ra0.2 microns, flatness 2 microns or less, ∥ 2 microns or less.Single plate size error between parts for 1 ~ 2 microns.

Double-disc grinding wheel features

1. High precision diamond grinding disc grinding and polishing once completed.

2. To shorten the processing time, in a short period of time to achieve high precision surface.

3. The original colour and lustre Bai Jinliang workpiece surface is metal.

4. For stainless steel plate, copper, aluminum, titanium alloy in the process of grinding, non-stick silk night, difficult to jam.

5. No scratches, no workpiece surface pitting.6. This product service life is long, reduce grinding disc wheel changed frequently.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Joe

- Address

- No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, Henan,450001 China

- Product Category

- Abrasive Tools,Abrasives

- Year Established

- 2010

- No. of Total Employees

- 51-100

- Company introduction

-

More Super Hard Products Co., Ltd Is Specialized In Manufacturing And Marketing Of Synthetic Diamond Tools, Cubic Boron Nitride(CBN) Tools, Which Is Widely Used In Petroleum And Geology Industry, Auto Aviation Processing Industry, Electric Processing Industry, Natural Diamond And Jewelry Processing Industry And Other Ultra- Precision Industry .

The Company Production And Sales Of Products Covered Vitrified Bond Tools, Resin Bond Tools, Metal Bond Tools, Electroplated Diamond/CBN Tools, Vaccum Brazed Products, CVD Diamond Tools, Polycrystalline Diamond (PCD) Tools, Cubic Boron Nitride (CBN) Tools.Our Objective Is To Meet All The Customers’ Needs And Help Every Customer Achieve Maximum Benefits. More Brings In Revenue For You, You Win, We Win!

More Super Hard Supplies The Wheels For Several Application Mainly:

* Carbide Round Tools On CNC Machines : Flute Grinding, Gash Grinding, End Facing, Clearance Angle And Cylindrical Grinding .

* Insert Grinding For Machines Such As: AGATHON, WENDT, HAAS, WAIDA And EWAG.

* Woodworking Saw Blade And Tools .

* HSS Tools .

* Cutting Wheels.

- Main Product

Related Products

sand paper (coated abrasive)

sand paper (Metal Application)

Diamond Tools: Diamond Blade, Diamond Polishing Pads, Diamond Grinding Wheel, Diamond Wire Saw

Mechanical Metal Spray Glass Bead Mold Sandblasted glassbead

Convex Polishing Pad for curved counter tops

China

China