Two Thermal Solutions For EV Battery Pack Cooling

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- GLPOLY

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Vehicle Accessories

Apply a video call to the Supplier

Thermal Interface Materials

- Verified Certificate

-

8

| Product name | Two Thermal Solutions For EV Battery Pack Cooling | Certification | - |

|---|---|---|---|

| Category | Other Vehicle Accessories | Ingredients | - |

| Keyword | thermal interface materials , thermal gap filler , thermally conductive structural adhesive | Unit Size | 5.0 * 5.0 * 30.0 cm |

| Brand name | GLPOLY | Unit Weigh | 1 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | 3926901000 |

Product Information

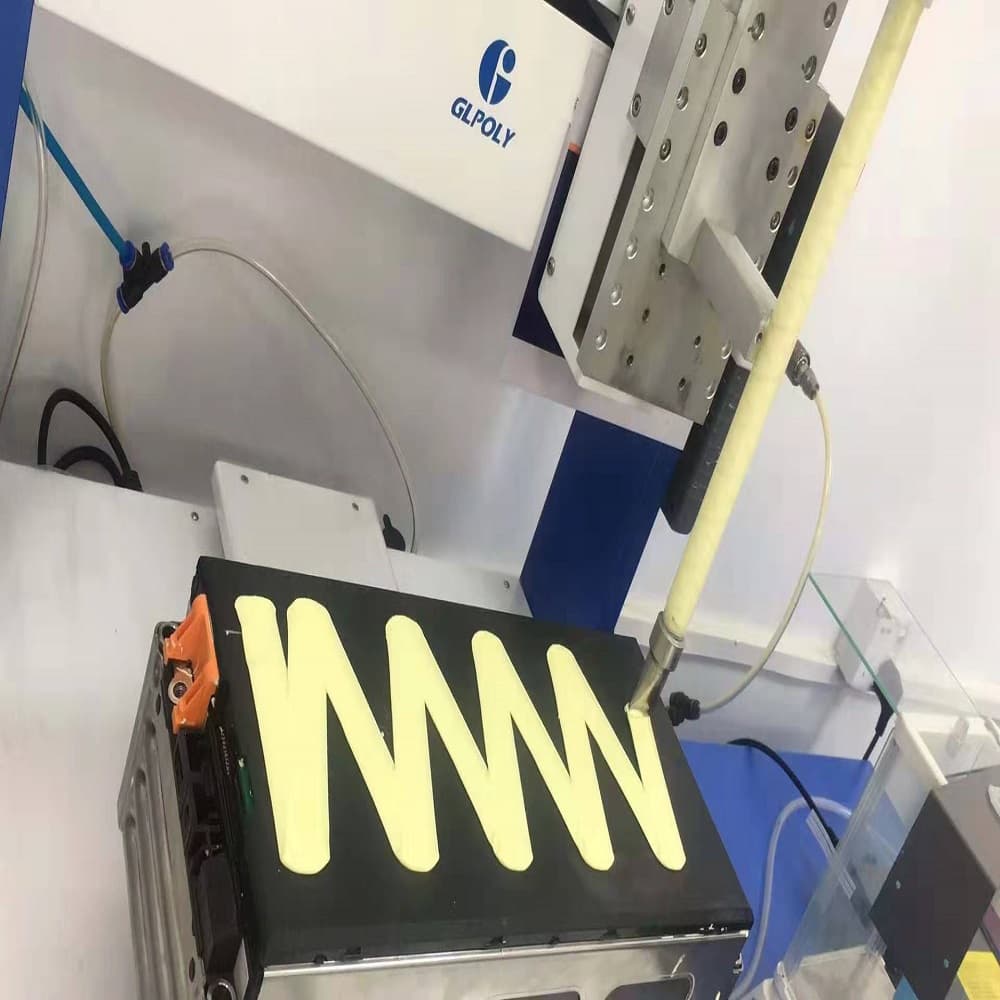

A new thermal interface material shows up along with the rise of CTP structural battery pack---thermally conductive structural adhesive. Many customers is confused by Thermally conductive structural adhesive and thermal gap filler. Here we introduce these two thermal interface materials briefly.

Firstly, literally thermally conductive structural adhesive has a strong bonding strength, eliminating the need of mechanical fasten. GLPOLY thermally conductive structural adhesive is designed for EV battery cell bond, with 8MPa bonding strength. Thermal gap filler is used for gap filling first, with soft natural tacky, no displacement or shift taken place.

Secondly, different rework status. Thermally conductive structural adhesive is not reworkable. After cured, this material provides a 8MPa bonding strength at least. It is destructive to take them apart. Thermal gap filler will cure as an elastomer pad, it’s easy to remove and clean up.

Thirdly, application sector is different. Thermally conductive structural adhesive is always used to applications where a rigid bonding is needed, integrated several components into an entirety. Thermal gap filler is widely used in consumer electronics, it’s soft tacky for ease of assembly.

Although they are different materials, both of them can be used to improve battery pack thermal management. The former one is used for cell bond, eliminating extra components, simplifying structure and increasing energy density, and the latter is usually used for modularized battery pack.

GLPOLY thermal interface materials are widely applied in EV battery pack, Motor, ECUs and automotive electronics etc, if you are struggling with thermal solution selection, please contact GLPOLY, we provide you considerate solution.

GLPOLY has engaged into thermal interface materials sector for more than 12 years, and partnered with top brands such as dJI, LG, Han’s SMC, DT Mobile, Freetech Pilot, GAC Motor, NIO Motor and more, providing them with exceptional performance thermal interface materials and advanced thermal solutions.

A new thermal interface material shows up along with the rise of CTP structural battery pack---thermally conductive structural adhesive. Many customers is confused by Thermally conductive structural adhesive and thermal gap filler. Here we introduce these two thermal interface materials briefly.

Firstly, literally thermally conductive structural adhesive has a strong bonding strength, eliminating the need of mechanical fasten. GLPOLY thermally conductive structural adhesive is designed for EV battery cell bond, with 8MPa bonding strength. Thermal gap filler is used for gap filling first, with soft natural tacky, no displacement or shift taken place.

Secondly, different rework status. Thermally conductive structural adhesive is not reworkable. After cured, this material provides a 8MPa bonding strength at least. It is destructive to take them apart. Thermal gap filler will cure as an elastomer pad, it’s easy to remove and clean up.

Thirdly, application sector is different. Thermally conductive structural adhesive is always used to applications where a rigid bonding is needed, integrated several components into an entirety. Thermal gap filler is widely used in consumer electronics, it’s soft tacky for ease of assembly.

Although they are different materials, both of them can be used to improve battery pack thermal management. The former one is used for cell bond, eliminating extra components, simplifying structure and increasing energy density, and the latter is usually used for modularized battery pack.

GLPOLY thermal interface materials are widely applied in EV battery pack, Motor, ECUs and automotive electronics etc, if you are struggling with thermal solution selection, please contact GLPOLY, we provide you considerate solution.

GLPOLY has engaged into thermal interface materials sector for more than 12 years, and partnered with top brands such as dJI, LG, Han’s SMC, DT Mobile, Freetech Pilot, GAC Motor, NIO Motor and more, providing them with exceptional performance thermal interface materials and advanced thermal solutions.

GLPOLY thermal interface materials are widely applied in EV battery pack, Motor, ECUs and automotive electronics etc, if you are struggling with thermal solution selection, please contact GLPOLY, we provide you considerate solution.

GLPOLY has engaged into thermal interface materials sector for more than 12 years, and partnered with top brands such as dJI, LG, Han’s SMC, DT Mobile, Freetech Pilot, GAC Motor, NIO Motor and more, providing them with exceptional performance thermal interface materials and advanced thermal solutions.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Mr. Kang

- Address

- Rm619, Huafeng Xinan Commercial Bulding, Baoan, Shenzhen China

- Product Category

- Other Electronic Components

- Year Established

- 1998

- No. of Total Employees

- 51-100

- Company introduction

-

GoldlinkTongda Electronics Co., Ltd is committed to thedesign, development and manufacture of Thermal Interface Materials, developing high qualityTIMs and Thermal Solution isour first priority. Our outstanding R&D team are ableto deliver the effective thermal solutions to customers for facing currentadvanced products.

Products

Ourbusiness includes Silicone Thermal Pad, Silicone Rubber Pad, Silicone PuttyPad, Silicone Thermal Tape, Thermal Interface Grease, Two-part Thermal InterfaceSealing Compound, Silicone Thermal Gel, Thermal Interface Phase Change Materialsand Non-Silicone type products.

Applications

We serve a multitude of industries worldwide includingNew energy vehicles, UAV,computer,telecommunications, consumer electronics, opticalproducts, LEDlighting, air flight, storage device, military and medicalequipment, powerconversion.

- Main Markets

-

China

China

Germany

Germany

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product

Related Products

KOREA GENUINE MOBIS OIL(AUTO LUBRICANT) 05200-484A0 (4L)

auto part interior lighting parts

Spare Parts for Renault Korea

Spare Parts for Kia Cars

Anti loose self locking nut