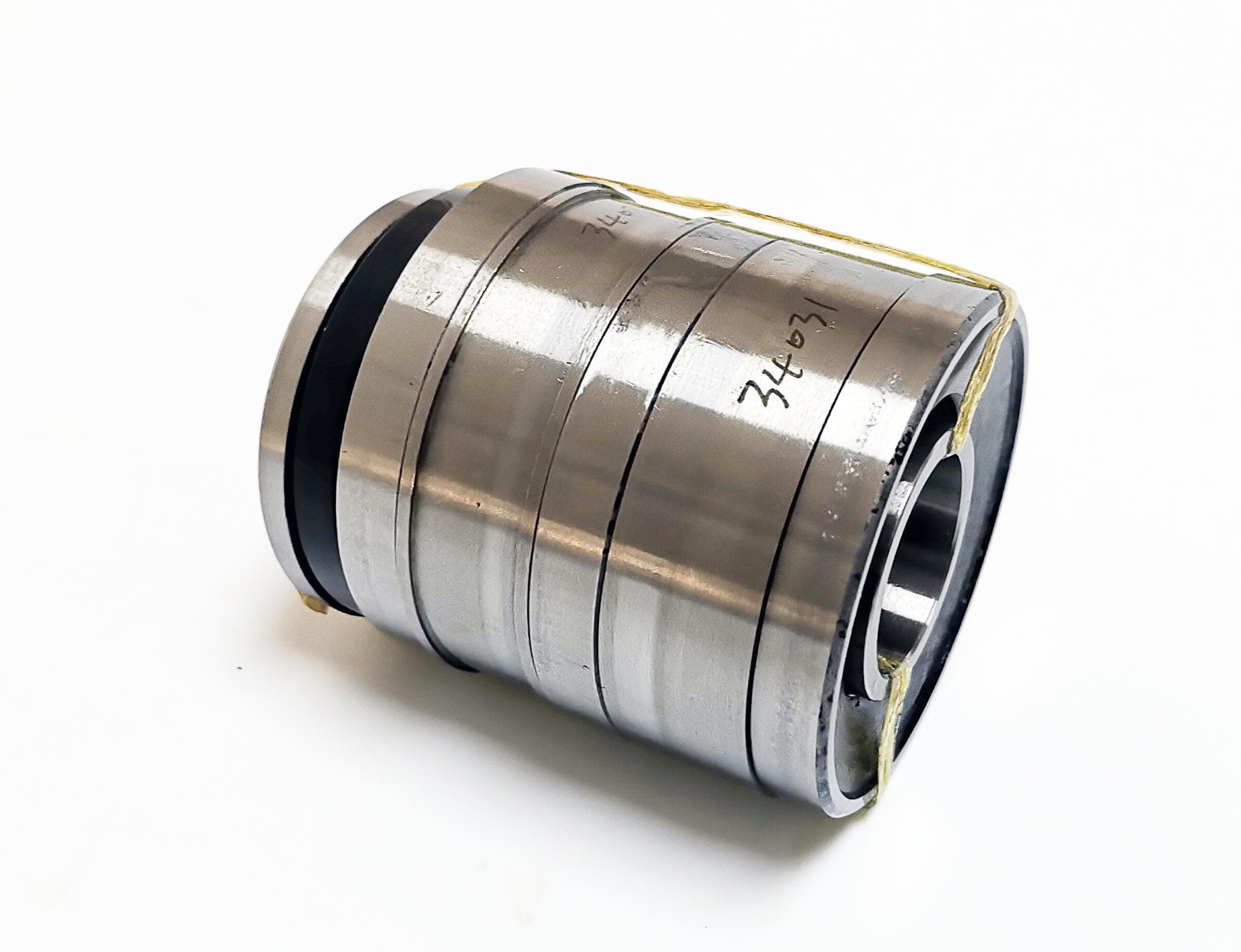

F-53507.T6AR Tandem Bearings for Extruder Gearboxes

Tandem Bearings for Extruder Gearboxes

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- MONTON

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Available,OBM,ODM,OEM

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Roller Bearings

Apply a video call to the Supplier

Luoyang Tandem bearings co.,ltd.

- Verified Certificate

-

10

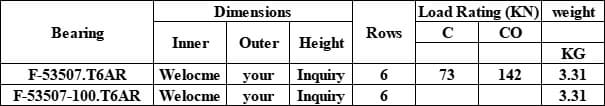

| Product name | F-53507.T6AR Tandem Bearings for Extruder Gearboxes | Certification | CE |

|---|---|---|---|

| Category | Roller Bearings | Material | - |

| Keyword | f-53507.t6ar , tandem bearings for extruder gearboxes | Unit Size | 50.0 * 80.0 * 350.0 mm |

| Brand name | MONTON | Unit Weigh | 5 kg |

| origin | China | Stock | 1500 |

| Supply type | Available,OBM,ODM,OEM | HS code | 8482 |

Product Information

Tandem Thrust bearings are also known as “Multi-Stage cylindrical roller thrust bearings” .

Tandem Thrust bearings are comprised of "stages" which include precision ground and matched thrust plates. These bearings also include compression sleeves separated by cylindrical roller assemblies. This design enables the Tandem Thrust bearings to provide a solution in a radial restricted envelope. The bearings are available in multiple stages, 2-8 to accommodate your design requirements. Depending on your preference, these bearings are available in a wide variety of sizes and options.

TandemThrust Bearings can receive heavy load in a limited space and support firmly in the direction of axis and last long with low frictional power. In addition, these bearings are moved by oil lubrication. Also thesetandem thrust bearings are used principally in gear boxes for single & twin screw extruders in the rubber and plastic industries.

1.Multi-stage cylindrical roller thrust bearing (basic type) adopts elastic spacer to connect the shaft washer,housing washer, roller and cage assembly.

The components of this Thrust Bearings are demountable. The user should assemble or dismount the bearing meticulously according to numeral order we provide.

2. Multi-stage cylindrical roller thrust bearing (shaft type) is made by penetrating an axis through theinner bore of basic type multi-stage cylindrical roller thrust bearing and fastening the bearing to the axis by locking collar. The components of this type of cylindrical roller thrust bearing are inseparable.

3. Multi-stage cylindrical roller thrust bearing (sleeve type) locking collar is made by covering a sleeveto the external of the basic type multi-stage cylindrical roller thrust bearing.It is also inseparable,and is assembled and disassembled as a whole.

Multi-Stage cylindrical roller thrust bearings(Tandem bearings) has the characteristics of limited radial space, high axial forces, equal support of all the rows of rollers and long operating life, and is the ideal spindle of parallel screw extruder.

The tandem bearings provided by our institute has the following types: double rows, three rows, four rows, five rows, six rows and eight rows, we also provided bearings with shaft and sleeve barrel. Customers can have their own selections according to center distance of screws, space and load (Figure 1~3). We also accept the orders of other dimensions.

Application of tandem bearings

When using tandem bearings, the following recommendations should be adhered to:

1. Preload: 1% of the dynamic basic load rating. The dynamic basic load rating of each tandem bearing see Figure 1~3. Figures not listed will be provided by out institute on request.

2. Radial guidance: full complement cylindrical roller bearings or needle roller bearings can be used.

3. Eliminate tilting: the supporting parts must be machined to eliminate any tilting.

4. Mounting tolerances: recommended the following mounting tolerances: shaft f6 and housing bore F7.

5. Lubrication: tandem bearings must always be lubricated by oil circulation (Figure 4)

1.Multi-stage cylindrical roller thrust bearing (basic type) adopts elastic spacer to connect the shaftwasher,housing washer, roller and cage assembly.

The components of this Thrust Bearings are demountable. The user should assemble or dismountthe bearing meticulously according to numeral order we provide.

2. Multi-stage cylindrical roller thrust bearing (shaft type) is made by penetrating an axis through theinner bore of basic type multi-stage cylindrical roller thrust bearing and fastening the bearing to theaxis by locking collar.The components of this type of cylindrical roller thrust bearing are inseparable.

3. Multi-stage cylindrical roller thrust bearing (sleeve type) locking collar is made by covering a sleeveto the external of the basic type multi-stage cylindrical roller thrust bearing.It is also inseparable,and is assembled and disassembled as a whole.

Shaft type:This type is another structure derived from the basic type. A shaft is put through the bore of the basic type. The bearing is fixed onto the shaft by some elastic snap ring. This type is not separable and must be mounted as a whole.

The following points must be observed when using tandem thrust bearings.

(1)Preload: 1% of rated dynamic load should be put on the bearings first.please refer to the following Fig1~3 for the rated dynamic load for each type.For those not listed in the figs, please contact technical service .

(2)Radial guidance:Full complement cylindrical roller bearings or needle roller bearings can be used.

(3)Slop avoiding:The supporting parts must be machined to avoid any slop.

(4)Mounting tolerance:For proper using of tandem thrust bearings,we recommend the following mounting tolerance:shaft f6 and bore F7.

(5)Lubricant:Tandem thrust bearings must be lubricated by rare oil regularly.

(6)Mounting:When mounting or dismantling the bearings, it is prohibited to use hammer or other heavy tools to knock on the bearing parts.

(7)Application examples:

As the tandem thrust bearings have the characteristics of limiting radial cross section, excellent axial loading capacity, long working life and low friction loss, they have been successfully used in the reduction gearbox for the parallel twin screw extruder in the plastic and rubber industry. Tandem thrust bearings are highly recommended to be used in other machines and equipment.

The locking collar is made by covering a sleeve to the external of the basic type multi-stage cylindrical roller thrust bearing. It is also inseparable, and is assembled and disassembled as a whole. So it is convenient to mount the bearing to the housing when it is used.

Applications:

a.Twin screw extruder

b.Pipe laying machines

c.Deep hole drilling

d.Oil pressing machine

Please feel free contact with for more technical support!

Normal type

Sleeve type

Shaft type

Tandem Thrust bearings are also known as “Multi-Stage cylindrical roller thrust bearings” .

Tandem Thrust bearings are comprised of "stages" which include precision ground and matched thrust plates. These bearings also include compression sleeves separated by cylindrical roller assemblies. This design enables the Tandem Thrust bearings to provide a solution in a radial restricted envelope. The bearings are available in multiple stages, 2-8 to accommodate your design requirements. Depending on your preference, these bearings are available in a wide variety of sizes and options.

TandemThrust Bearings can receive heavy load in a limited space and support firmly in the direction of axis and last long with low frictional power. In addition, these bearings are moved by oil lubrication. Also thesetandem thrust bearings are used principally in gear boxes for single & twin screw extruders in the rubber and plastic industries.

1.Multi-stage cylindrical roller thrust bearing (basic type) adopts elastic spacer to connect the shaft washer,housing washer, roller and cage assembly.

The components of this Thrust Bearings are demountable. The user should assemble or dismount the bearing meticulously according to numeral order we provide.

2. Multi-stage cylindrical roller thrust bearing (shaft type) is made by penetrating an axis through theinner bore of basic type multi-stage cylindrical roller thrust bearing and fastening the bearing to the axis by locking collar. The components of this type of cylindrical roller thrust bearing are inseparable.

3. Multi-stage cylindrical roller thrust bearing (sleeve type) locking collar is made by covering a sleeveto the external of the basic type multi-stage cylindrical roller thrust bearing.It is also inseparable,and is assembled and disassembled as a whole.

Multi-Stage cylindrical roller thrust bearings(Tandem bearings) has the characteristics of limited radial space, high axial forces, equal support of all the rows of rollers and long operating life, and is the ideal spindle of parallel screw extruder.

The tandem bearings provided by our institute has the following types: double rows, three rows, four rows, five rows, six rows and eight rows, we also provided bearings with shaft and sleeve barrel. Customers can have their own selections according to center distance of screws, space and load (Figure 1~3). We also accept the orders of other dimensions.

Application of tandem bearings

When using tandem bearings, the following recommendations should be adhered to:

1. Preload: 1% of the dynamic basic load rating. The dynamic basic load rating of each tandem bearing see Figure 1~3. Figures not listed will be provided by out institute on request.

2. Radial guidance: full complement cylindrical roller bearings or needle roller bearings can be used.

3. Eliminate tilting: the supporting parts must be machined to eliminate any tilting.

4. Mounting tolerances: recommended the following mounting tolerances: shaft f6 and housing bore F7.

5. Lubrication: tandem bearings must always be lubricated by oil circulation (Figure 4)

1.Multi-stage cylindrical roller thrust bearing (basic type) adopts elastic spacer to connect the shaftwasher,housing washer, roller and cage assembly.

The components of this Thrust Bearings are demountable. The user should assemble or dismountthe bearing meticulously according to numeral order we provide.

2. Multi-stage cylindrical roller thrust bearing (shaft type) is made by penetrating an axis through theinner bore of basic type multi-stage cylindrical roller thrust bearing and fastening the bearing to theaxis by locking collar.The components of this type of cylindrical roller thrust bearing are inseparable.

3. Multi-stage cylindrical roller thrust bearing (sleeve type) locking collar is made by covering a sleeveto the external of the basic type multi-stage cylindrical roller thrust bearing.It is also inseparable,and is assembled and disassembled as a whole.

Shaft type:This type is another structure derived from the basic type. A shaft is put through the bore of the basic type. The bearing is fixed onto the shaft by some elastic snap ring. This type is not separable and must be mounted as a whole.

The following points must be observed when using tandem thrust bearings.

(1)Preload: 1% of rated dynamic load should be put on the bearings first.please refer to the following Fig1~3 for the rated dynamic load for each type.For those not listed in the figs, please contact technical service .

(2)Radial guidance:Full complement cylindrical roller bearings or needle roller bearings can be used.

(3)Slop avoiding:The supporting parts must be machined to avoid any slop.

(4)Mounting tolerance:For proper using of tandem thrust bearings,we recommend the following mounting tolerance:shaft f6 and bore F7.

(5)Lubricant:Tandem thrust bearings must be lubricated by rare oil regularly.

(6)Mounting:When mounting or dismantling the bearings, it is prohibited to use hammer or other heavy tools to knock on the bearing parts.

(7)Application examples:

As the tandem thrust bearings have the characteristics of limiting radial cross section, excellent axial loading capacity, long working life and low friction loss, they have been successfully used in the reduction gearbox for the parallel twin screw extruder in the plastic and rubber industry. Tandem thrust bearings are highly recommended to be used in other machines and equipment.

The locking collar is made by covering a sleeve to the external of the basic type multi-stage cylindrical roller thrust bearing. It is also inseparable, and is assembled and disassembled as a whole. So it is convenient to mount the bearing to the housing when it is used.

Applications:

a.Twin screw extruder

b.Pipe laying machines

c.Deep hole drilling

d.Oil pressing machine

Please feel free contact with for more technical support!

Normal type

Sleeve type

Shaft type

Tandem Thrust bearings are also known as “Multi-Stage cylindrical roller thrust bearings” .

Tandem Thrust bearings are comprised of "stages" which include precision ground and matched thrust plates. These bearings also include compression sleeves separated by cylindrical roller assemblies. This design enables the Tandem Thrust bearings to provide a solution in a radial restricted envelope. The bearings are available in multiple stages, 2-8 to accommodate your design requirements. Depending on your preference, these bearings are available in a wide variety of sizes and options.

TandemThrust Bearings can receive heavy load in a limited space and support firmly in the direction of axis and last long with low frictional power. In addition, these bearings are moved by oil lubrication. Also thesetandem thrust bearings are used principally in gear boxes for single & twin screw extruders in the rubber and plastic industries.

1.Multi-stage cylindrical roller thrust bearing (basic type) adopts elastic spacer to connect the shaft washer,housing washer, roller and cage assembly.

The components of this Thrust Bearings are demountable. The user should assemble or dismount the bearing meticulously according to numeral order we provide.

2. Multi-stage cylindrical roller thrust bearing (shaft type) is made by penetrating an axis through theinner bore of basic type multi-stage cylindrical roller thrust bearing and fastening the bearing to the axis by locking collar. The components of this type of cylindrical roller thrust bearing are inseparable.

3. Multi-stage cylindrical roller thrust bearing (sleeve type) locking collar is made by covering a sleeveto the external of the basic type multi-stage cylindrical roller thrust bearing.It is also inseparable,and is assembled and disassembled as a whole.

Multi-Stage cylindrical roller thrust bearings(Tandem bearings) has the characteristics of limited radial space, high axial forces, equal support of all the rows of rollers and long operating life, and is the ideal spindle of parallel screw extruder.

The tandem bearings provided by our institute has the following types: double rows, three rows, four rows, five rows, six rows and eight rows, we also provided bearings with shaft and sleeve barrel. Customers can have their own selections according to center distance of screws, space and load (Figure 1~3). We also accept the orders of other dimensions.

Application of tandem bearings

When using tandem bearings, the following recommendations should be adhered to:

1. Preload: 1% of the dynamic basic load rating. The dynamic basic load rating of each tandem bearing see Figure 1~3. Figures not listed will be provided by out institute on request.

2. Radial guidance: full complement cylindrical roller bearings or needle roller bearings can be used.

3. Eliminate tilting: the supporting parts must be machined to eliminate any tilting.

4. Mounting tolerances: recommended the following mounting tolerances: shaft f6 and housing bore F7.

5. Lubrication: tandem bearings must always be lubricated by oil circulation (Figure 4)

1.Multi-stage cylindrical roller thrust bearing (basic type) adopts elastic spacer to connect the shaftwasher,housing washer, roller and cage assembly.

The components of this Thrust Bearings are demountable. The user should assemble or dismountthe bearing meticulously according to numeral order we provide.

2. Multi-stage cylindrical roller thrust bearing (shaft type) is made by penetrating an axis through theinner bore of basic type multi-stage cylindrical roller thrust bearing and fastening the bearing to theaxis by locking collar.The components of this type of cylindrical roller thrust bearing are inseparable.

3. Multi-stage cylindrical roller thrust bearing (sleeve type) locking collar is made by covering a sleeveto the external of the basic type multi-stage cylindrical roller thrust bearing.It is also inseparable,and is assembled and disassembled as a whole.

Shaft type:This type is another structure derived from the basic type. A shaft is put through the bore of the basic type. The bearing is fixed onto the shaft by some elastic snap ring. This type is not separable and must be mounted as a whole.

The following points must be observed when using tandem thrust bearings.

(1)Preload: 1% of rated dynamic load should be put on the bearings first.please refer to the following Fig1~3 for the rated dynamic load for each type.For those not listed in the figs, please contact technical service .

(2)Radial guidance:Full complement cylindrical roller bearings or needle roller bearings can be used.

(3)Slop avoiding:The supporting parts must be machined to avoid any slop.

(4)Mounting tolerance:For proper using of tandem thrust bearings,we recommend the following mounting tolerance:shaft f6 and bore F7.

(5)Lubricant:Tandem thrust bearings must be lubricated by rare oil regularly.

(6)Mounting:When mounting or dismantling the bearings, it is prohibited to use hammer or other heavy tools to knock on the bearing parts.

(7)Application examples:

As the tandem thrust bearings have the characteristics of limiting radial cross section, excellent axial loading capacity, long working life and low friction loss, they have been successfully used in the reduction gearbox for the parallel twin screw extruder in the plastic and rubber industry. Tandem thrust bearings are highly recommended to be used in other machines and equipment.

The locking collar is made by covering a sleeve to the external of the basic type multi-stage cylindrical roller thrust bearing. It is also inseparable, and is assembled and disassembled as a whole. So it is convenient to mount the bearing to the housing when it is used.

Applications:

a.Twin screw extruder

b.Pipe laying machines

c.Deep hole drilling

d.Oil pressing machine

Please feel free contact with for more technical support!

Normal type

Sleeve type

Shaft type

- Product Info Attached File

- Verified Certificate

-

B2B Trade

| Price (FOB) | Negotiable | transportation | Air Transportation,Express,Land Transportation,Negotiation Other,Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- LI XINGWEN

- Address

- Huaxia Road No.1, High-tech Development Zone, Luoyang City, P.R.China

- Product Category

- Ball Bearings,Bearings,Roller Bearings

- Year Established

- 2003

- No. of Total Employees

- 1-50

- Company introduction

-

- Main Markets

-

China

China

India

India

South Korea

South Korea

U.A.E.

U.A.E.

U.S.A

U.S.A

- Main Product