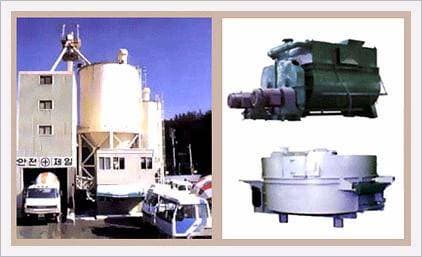

Batcher Plant

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Apply a video call to the Supplier

BMI Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | Batcher Plant | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Characteristics

Top classed domestic overall maker

We design, manufacture, install and do after service on all elements of batcher

plant such as aggregate facility, hopper, mixer, etx.

High technology and dependatble installation

Our research team has been highly stress on higher efficiency and dependable

installation, based on field experience, so that clients can satisfy from planning,

over all layout, technological advice, install, instant as and providing parts.

Batcher plant based on field experience.

Based on field experience our batcher plant design, produce, and install to

fit any field condition by various models.

Compositions

|

|

1.Weighing hopper for Gravel and

Sand Gravel weigher is of structure, attached to load cell, installed underneath aggregate storage site and operated by air cylinder.The gate of the scale is perfectly scaled by the control system, and two fill valves for perfect scaling jog it. In case any one of the two aggregate fill valves is defective, scaling is still done correctly by the other fill valve. The slide valve is also installed to enable control of quantity of dropping aggregate and easiness of maintenance. The gravel weighers are located in the aggregate stockyard. |

|

2.Weighing Hopper for Cement It is of the same structure as the aggregate weighing hopper, the scale and discharge gates are enclosed by as canvas, where an air cylinder controls the discharge valve of a butterfly valve type. Air vent pipe allows ideal airflow for weighing and discharging to be done properly. |

|

|

3.Weighing Hopper for Water and

Admixture Admixture weighing hopper is fitted on top of the water-weighing hopper. It allows the water-weighing hopper to re-weigh the admixture. The values for water and admixture are of a ball valve type, and an auxiliary water tank is installed inside main unit of each batcher plant, and the admixture diluted in a ground tank for direct scaling. |

|

|

4.Bag Fitler Dust generated when each aggregate is pored into the mixer is induced through a duct into bag filter and re-cycled into the mixer, preventing air pollution as well as scaling error and loss. |

|

|

5.Concrete Hopper Concrete mixed in the mixer is discharged through the concrete hopper. The capacity of the hopper is dependent on that of the mixer, and an additional service pad is fitted around the concrete hopper for easy and convenient repair and service works. The concrete hopper is open and closed by a double clam rubber gate. |

Specifications

|

PLANT CAPACITY0

|

60m3 /H

|

90m3 /H

|

120m3 /H

|

150m3 /H

|

210m3 /H

|

ABOVE SLUMP 8cn

|

|

|

MIXER

|

MODEL

|

BM 1000

|

BM 1500

|

BM 2000

|

BM 2500

|

BM 3500

|

TWO SHAFT MIXER

|

|

CAPA

|

1.0

|

1.5

|

2.0

|

2.5

|

3.5

|

||

|

MIXER MOTOR

(Kw x Unit) |

15x2

|

22x2

|

30x2

|

37x2

|

55x2

|

||

|

BELT

CONVEYOR |

MOTOR(Kw)

|

11/15

|

15/22

|

22/30

|

30/37

|

30/37

|

|

|

WIDTH(mm)

|

600

|

700

|

900

|

1,050

|

1,050

|

||

|

STD LENTH(M)

|

28/21

|

28/21.7

|

28/21.8

|

28/22.5

|

28/23.3

|

||

|

CAPA(T/H)

|

600

|

600

|

800

|

1,000

|

1,000

|

||

|

WEIGHER

CAPACITY (Kg) |

GRAVEL(1,2)

|

2,000

|

2,500

|

3,000

|

3,500

|

4,500

|

COMMON SIZE FOR G1,2

|

|

SAND

|

2,000

|

2,500

|

2,500

|

3,500

|

4,500

|

||

|

CEMENT

|

500

|

750

|

1,000

|

1,200

|

1,500

|

||

|

WATER

|

300

|

400

|

500

|

600

|

750

|

||

|

ADMIXTURE

(1,2) |

20

|

20

|

20

|

20

|

50

|

SELECTION OF

2KINDS 5 |

|

|

CONCRETE HOPPER CAPA(m3)

|

2.0

|

2.5

|

3.0

|

4.0

|

5.5

|

||

|

CEMENT BIN CAPA(m3)

|

2.1

|

2.1

|

2.5

|

2.5

|

3.2

|

||

|

WATER TANK CAPA(m3)

|

1.4

|

2.0

|

2.4

|

3.0

|

3.8

|

||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- LEE SANG YUN

- Address

- 770-1, Yehyeon-ri, Guji-myeon, Dalsung-gun, Daegu

- Product Category

- Cast & Forged

- No. of Total Employees

- 1-50

- Company introduction

-

Headquartered in Taegu, we have provided equipment and state of the art technology with the accumulated experience in the field.

Followings are our major products.

1. Casting plant, Rolling Mill plant, Industrial plant

2. Asphalt mixing plant, Batcher plant, Crushing plant

3. Parking systemWe will do our best to satisfy our customers with the eminent quality of products. If you have any inquiry regarding our products, contact us without hesitation. We are looking forward to hearing from you soon.

- Main Markets

-

Japan

Japan

- Main Product