Clean Tank

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- DOHA INDUSTRY CO.,LTD

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- clean tank, smc water tank

- Category

- Water Treatment , Other Constructions

Apply a video call to the Supplier

DOHA Industry Co., Ltd.

- Verified Certificate

-

16

| Product name | Clean Tank | Certification | - |

|---|---|---|---|

| Category |

Water Treatment

Other Constructions |

Ingredients | - |

| Keyword | clean tank , smc water tank | Unit Size | - |

| Brand name | DOHA INDUSTRY CO.,LTD | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 3925100000 |

Product Information

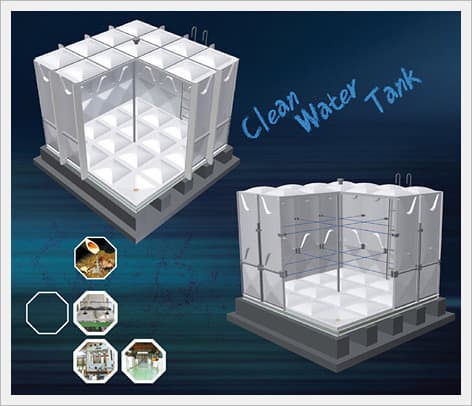

High Quality SMC Panel

Water Tank

Safety

We pursue the best system through strict design criteria, quality management and reliable structural strength analysis.

The basic structure analysis is design by safety factors against threshold values. Doha's know-how lies in the optimal safety factor in consideration of external force in the design that is expected based on physical properties after long-term use of SMC material for than 15 years.

In designing, the doha Clean Tank ignores initial value (100%) of the physical properties of SMC material and considers the safety factor to a minimum value(70%). Therefore, the doha Clean Tank guarantees long-term endurance.

| Design criteria : External force < Physical properties at the threshold/safety factor | |

|

Items

|

Design conditions |

|

Earthquake

|

Lateral seismic coefficient Kh=1/3G |

|

hydrostatic pressure

|

Based on 3.3 times of hydrostatic pressure Strain at the time of a filled tank of water : less than 1% of the height of the tank |

|

Snow load

|

60kg/m2 |

|

Wind load

|

Less than 60m/sec |

|

Intensity of illumination

|

Less than 0.1% |

|

Water temperature

|

Workable temperature : Less than 30°C Maximum temperature : Less than 40°C |

| *Overseas quality certificates : Singapore(PSB), U.K(WRAS) | |

Free capacity design

Using panels of various sizes, the ECO Clean Tank utilizes horizontal and vertical space at the maximum and those are suitable for an underground reserve tank of large capacity. It operates a corner-type system.

|

Possible height to install tank

|

Possible capacity to install tank

|

|

1.0M~6.0M in height

|

1Ton~5,000Tons (The capacity exeeding 5000 tons can be installed by separate design.)) |

Large capacity type :

Best Hygienic Properties

With the use of excellent corrosion-resistant panels, the surface of the tank is uniformly smooth without any moss growth and therefore, enables long-term use as the panels inhibit the proliferation of bacteria and other various germs by perfectly blocking all light from outside.

Materials for Reinforced Components

|

Inside

|

for Liquid part

|

Stainless Steel(STS)

|

|

for Air part

|

Plastic or corrosion-resistant material

|

|

|

Outside

|

Steel + hot galvanizing

|

|

Products with Inferior Hygienic Properties

Performance evaluation criteria of the panel

|

Item

|

Performance criteria

|

|

|

Mechanic strength

|

1) Tensile strength |

More than 60Mpa

|

| 2) Flexural strength |

More than 80Mpa

|

|

| 3) Flexural modulus |

More than 6000Mpa

|

|

| 4) Barcol hardness |

More than 30

|

|

| 5) Absorption |

Less than 1%

|

|

|

Elution of toxic substances

|

1) Heavy metals |

Less than 0.1% ppm

|

| 2) Consumption of KOnO4 |

Less than 10ppm

|

|

| 3) pH |

5.8~8.6

|

|

| 4) Phenol |

Less than 0.005ppm

|

|

| 5) Oily substance before evaporation |

Less than 30ppm

|

With years of experties in structure design, we provide perfect structure safety

Optimal Structure Design

We performed structure analysis by the Finite Element Method to secure credibility on a reinforcement system and the intensity of panels and pursue the optimal design.

By inputting all possible factors such as hydrostatic pressure, seismic load, snow load, wind load, etc., we estimated the stress and distortion level. Through intensive reinforcement on the part with maximum stress, we aimed to design the best stable system.

Structural Analysis Flow chart

Stress Analysis of the Panel(FEM)

Long-term Durability Test(Field test)

Generally, there is more than one water depletion and filling up a water tank per day, on the average. Therefore, if the tank is used for 15years, approximately 4000 times of water circulation would occur and the tank would undergo about 4000 repetitive loads. Through the field test before launching new products into the market, the Hi Tank undergoes actually expected repetitive loads by letting the water circulate for 6 months day and night using two tanks. After checking for water leakage and other defects from such tests to guarantee safety and endurance, we launch the product into the market.

**External reinforcement system is applying (1~3mH)

External reinforcement beam

-External reinforcement design that is structurally safe without internal reinforcement material.

-Reinforcement structure focusing on endurance and hygiene.

Outstanding thermal effect(option)

With the excellent insulating effect of the material and single-unit polyurethane thermal material, our tank demonstrates outstanding thermal effect and prevents freezing and dew condensation. (Adapted weatherproof-treated thermal cover)

Watertight Construction of the Panel

Maintains perfect watertight function by using tape=type sealant, a PVC foam with an excellent weatherproof function and restoration.

External ladder

-Considering the safety when entering the manhole, the grip part of the ladder is made in round form.

-Easy to use and excellent in appearance.

Roof support/internal ladder

-Used reinforced plastic which is same material for the panel, contains no rust and does have excellent mechanical strength.

Hot dip galvanized bolts

-The coated surface is not damaged when assembling with an impact wrench to a thickness of a coating surface more than 40m in thickness.

Drainage structure at the bottom

-We use a drainage panel on the bottom to collect and discharge the water.

Internal/External Complex Reinforcement System

The water tank exceeding 3mH in height adapts and internal/external complex reinforcement system that minimizes using reinforcement materials inside the tank and secures hygienic and structural safety.

**In particular, in order to prevent erosion due to chlorice gas, the structure without an inside reinforcement stay is applied to the top part.

Internal reinforcement system provides the followings.

- In the event that the space for installing a tank is narrow, a proper reinforcement system enhances the utility of the installation space.

- By applying a PE coating to the inner stay rust generation is minimized on the stainless steel part on the top part.

Composition of panel

Standard composition of side panels by height

Kinds and shapes

The real outline dimensions(W,L,H) are as follows

|

W

|

L

|

H

|

|

Normal dimension + 150mm

|

Normal dimension + 150mm

|

Normal dimension +100mm

|

Specification and space for concrete foundation

Based on PAD production

- Width : More than 400mm

- Height : More than 600mm(including base frame)

- Interval distance : Less than 1m at maximum

- Outline dimension : W, L + 400mm

- Horizontality degree : Less than 1/500(Maintains smoothness at the upper part)

Installation space : A space for 600mm apart from the walls in four directions(1000mm for the upper part) is required for the installation of a tank and for its inspection and maintenance.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- KIM, WHAN-KYU

- Address

- 1183, Songhyeon-ri, Jillye-myeon, Gimhae-si, Gyeongsangnam-do, 621-882 KOREA

- Product Category

- Construction Machinery Parts,Water Treatment

- No. of Total Employees

- 101-500

- Company introduction

-

We, Doha, are specialized in parts & raw material for many years, which reserve environmental-friendly and secured basis technology developed by our R&D team with high-tech facilities producing composite & engineering plastic parts in variety manufacturing process. By the reason above, we have produced and supplied global maker "Volvo and Clark" , Hyundai heavy M/C, Daedong, Dongyang, Kukjae, LG etc. with car parts, heavy equipment parts, leisure & agricultural machinery which meet international standard. We have given the impression to our clients by offering superb products which are going over to our clients' view. Especially, our R&D team endeavors to localize in new part material & environment-friendly material by R&D as re-born to truly specializing parts and raw material company.

- Main Markets

-

China

China

France

France

Germany

Germany

Indonesia

Indonesia

Japan

Japan

- Main Product

South Korea

South Korea