Friction Stir Spot Joining System

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Apply a video call to the Supplier

Winxen

- Verified Certificate

-

16

| Product name | Friction Stir Spot Joining System | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

|

The friction stir welding, FSW, is a solid state welding process.

|

Friction stir welding system (FSW)

Features

- A 5-axis control gantry type of high rigidity structure

- A position control algorithm through a servo system

- Acquisition of data through software

- Compatibility pursuant to jig and tool change

Major application

- Aluminum alloy, magnesium alloy,

copper alloy of light weight

- Metal junction

- Junction of hetero-metals

- Electric-electronic/aircraft/automobile/ship/train fields

- LCD process(Backing Plate)

- Welding of various Al frames

|

Items

|

STAND TYPE

|

|

|

TYPE

|

A 2-dimensional friction stir welding machine | |

|

Control system

|

Motion Control Unit | |

|

Table Size

|

1,200mm x 2,000mm | |

|

STROKE

|

X

|

2,000mm |

|

Y

|

1,20mm | |

|

Z

|

400mm | |

|

Moving speed

|

X

|

side Junction speed: 100~600mm/sec (Max : 2,000mm/sec) |

|

Y

|

side Junction speed: 100~600mm/sec (Max : 2,000mm/sec) |

|

|

Z

|

900mm/sec | |

|

C axis

|

±360 max 22rpm | |

|

TILTING angle

|

0˚ ~ 5˚ | |

|

SPINDLE revolution

|

500~3,000rpm(15kw) | |

|

Consumed power

|

AC380V,3Φ, 60Hz | |

|

Operation methods

|

Automatic(Touch Screen)/manual | |

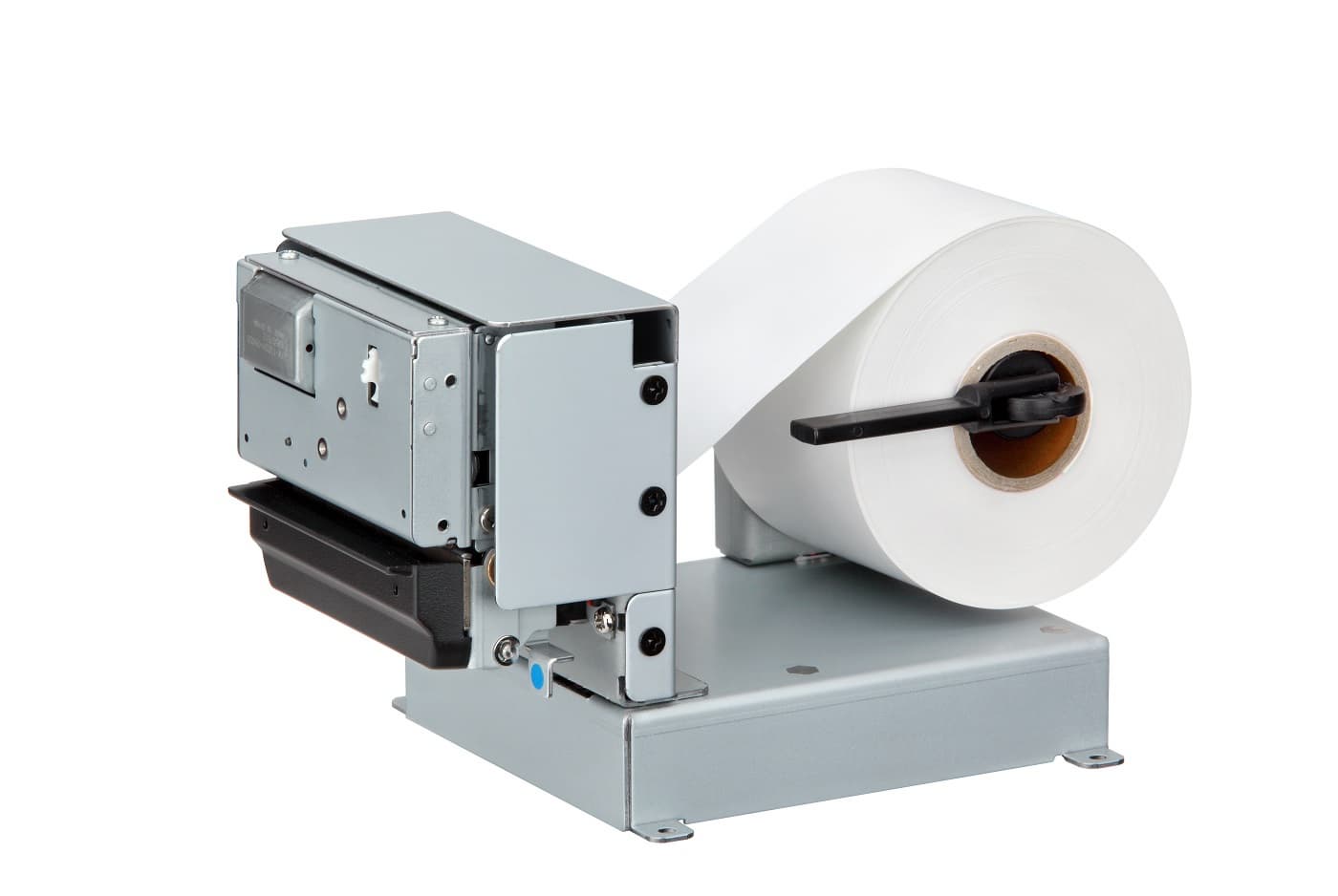

Friction stir spot joining system (FSJ)

Robot type friction stir spot joining system

Features

- Light weight metal joining overlap welding of aluminum alloy, etc.

- Maintenance of high accuracy with up/down movement structure in Z-axis of

spindle type(under application for patent)

- Pressure/position control algorithm through a servo system

- Acquisition of data through software

Major application

- Hod

- Lift Gate

- Rear Door

- Lid Panel

- Heat Insulant

- Other panel spot joints of AI material

|

Items

|

STAND TYPE

|

GUN TYPE

|

|

|

Control system

|

Motion Controller Unit

|

||

|

z axis

|

Operation type

|

AC SERVO MOTOR operation

(pressurization, revolution common) |

|

|

Allowable junction reactions

|

1,000kgf

|

500kgf

|

|

|

Revolution ranges

|

0~4,500RPM

|

||

|

Pressurization stroke

|

max, 160mm

|

||

|

Consumed power

|

AC220± 10%, 3Φ, 60Hz

|

||

|

Operation method

|

Automatic(Touch Screen)/manual

|

||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Taesung Roh

- Address

- 119-2, Sinchon-dong, Changwon Si, Gyeongnam,Korea, 642-370

- Product Category

- Refrigeration & Heat Exchange Machinery

- No. of Total Employees

- 51-100

- Company introduction

-

Since launch in January 1, 2001, Winxen has been developing a variety of technologies needed in future industries, and by focusing on developing and producing of creative products through them. Winxen want to be reborn as a global engineering company running in a unique culture by developing all different advanced sensors and systems, developing the energy conversion system and robot technology, developing next generation numerical control machine tools, developing new IT products applying some of the technologies from the expanding video game market, developing environment friendly products.

- Main Product

South Korea

South Korea