S.D.M PROCESS

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- drying, drying module process

- Category

- Other Machinery & Industry Equipment

Apply a video call to the Supplier

SAC Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | S.D.M PROCESS | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | drying , drying module process | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

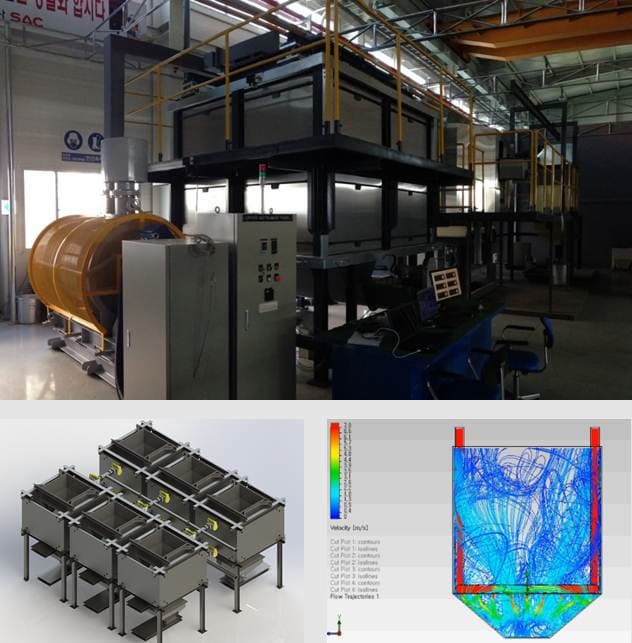

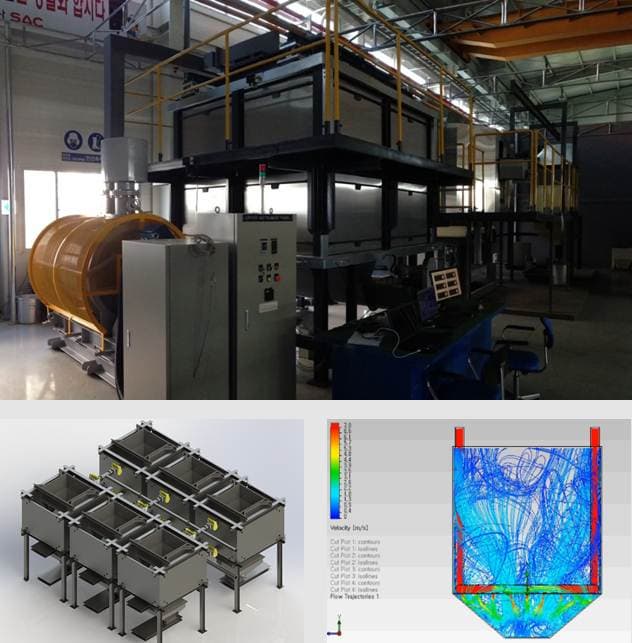

Drying Module Process

- Input Condition : Max. 80% of Moisture Content

- Output Condition : 3 - 10% of Moisture Content

Features

- Continuous Type

- Full Automation by Industrial Computer

- Fit up Heat Exchanger

- Excellent Temperature Distribution

- Multi-Stage Blower

- Electric Heat or Fuel Burner Type

Advantages

- Excellent Energy Saving (Reduction 35%)

- Quality Improvement

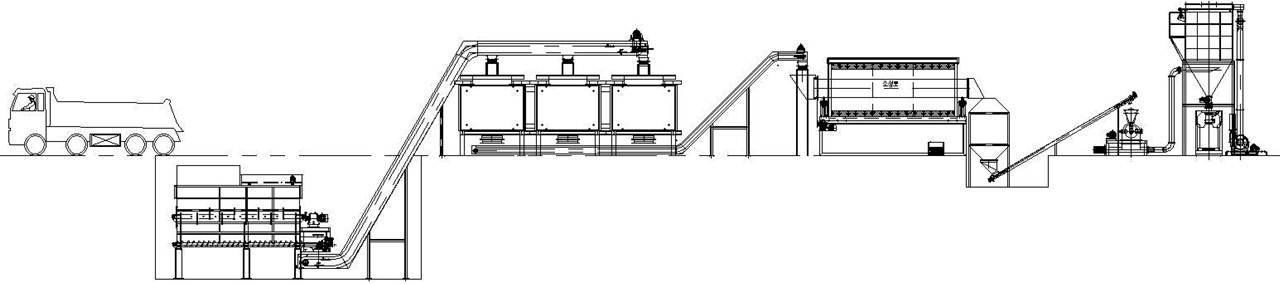

Process Lay-Out

- Inlet Hopper- - Drying Module- - Retort- -Supplementary-

*Raw material *Low temp. dry *High temp. dry *Crasher

(Under 100℃) Depend on product *Packing

Excellent Energy Saving (Reduction 35%)

Water Sludge Drying Module Process

Water Sludge Drying Module Process

- Capacity 5ton/day - 100ton/day

- Input Condition : 75% of Moisture Content

- Output Condition : 3% - 30% of Moisture Content

- Process Temp : Dry Under 100℃

Retort 400℃ - 900℃

Sewage Sludge Drying Module Process

- Capacity : 5ton/day - 500ton/day

(Depend on process)

- Input Condition : 75% of Moisture Content

- Output Condition : Under 10% of Moisture Content

- Process Temp. : Dry Under 100℃. Kiln 300℃ - 400℃

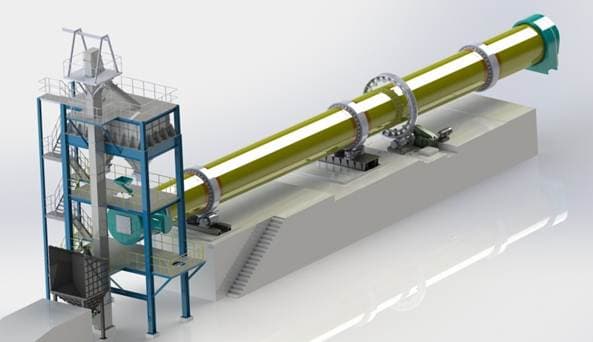

Ore Drying Process

- Capacity 2,000 ton/day (Depend on Process)

- Input condition : 30% - 40% of Moisture Content

- Output Condition : Under 1% of Moisture Content

- Process Temp : Dry Under 100℃

Kiln 850℃ - 900℃

And More : Metallurgy, Ore ( Fe, Zn, Cr, Mn, etc ), Slag, Coal, Metal

Powder, Diatomite, etc

Saving Energy, Make New Value

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- HAN, HYOUNG-KI

- Address

- 764-1, Yulgum-ri, Songhwan-eup, Chonan-si, Chungcheongnam-do, Korea

- Product Category

- Other Machinery & Industry Equipment

- No. of Total Employees

- 51-100

- Company introduction

-

Enviroment - friendly energy saving - technology for Green Development. SAC has developed new technologies including Low pressure Carburizing and High Pressure Gas Quenching and Low Pressure Carburizing and Oil Q-uenching.

SAC is growing fast as a leading manufacturer and exporter of ex-porter of environment friendly furnaces with its state-of-the-art technology in the world market.

SAC would be jumpaing up to international environmentally friendly company which achieve 500 billion sales through the mangement vision of satisfaction, achievement and creative.

- Main Markets

-

China

China

Hong Kong(China)

Hong Kong(China)

India

India

Japan

Japan

Philippines

Philippines

- Factory Information

-

SAC

- Main Product

Related Products

NEMA17 42mm stepper motor with driver or controller

Audio Grade PCIe Host Card – tX-USBexp

Jet Fan(1800~2400CMH)

Marine Loading Arm

Spare Parts for Hydraulic Breaker