sunlight l-200

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- sunlight, sunlight l-200, high temperature tape, htt sunlight

- Category

- Industrial Supplies

Apply a video call to the Supplier

Daehyun tech., inc

- Verified Certificate

-

10

| Product name | sunlight l-200 | Certification | - |

|---|---|---|---|

| Category | Industrial Supplies | Ingredients | - |

| Keyword | sunlight , sunlight l-200 , high temperature tape , htt sunlight | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

| 1 | GENERAL | ||||||

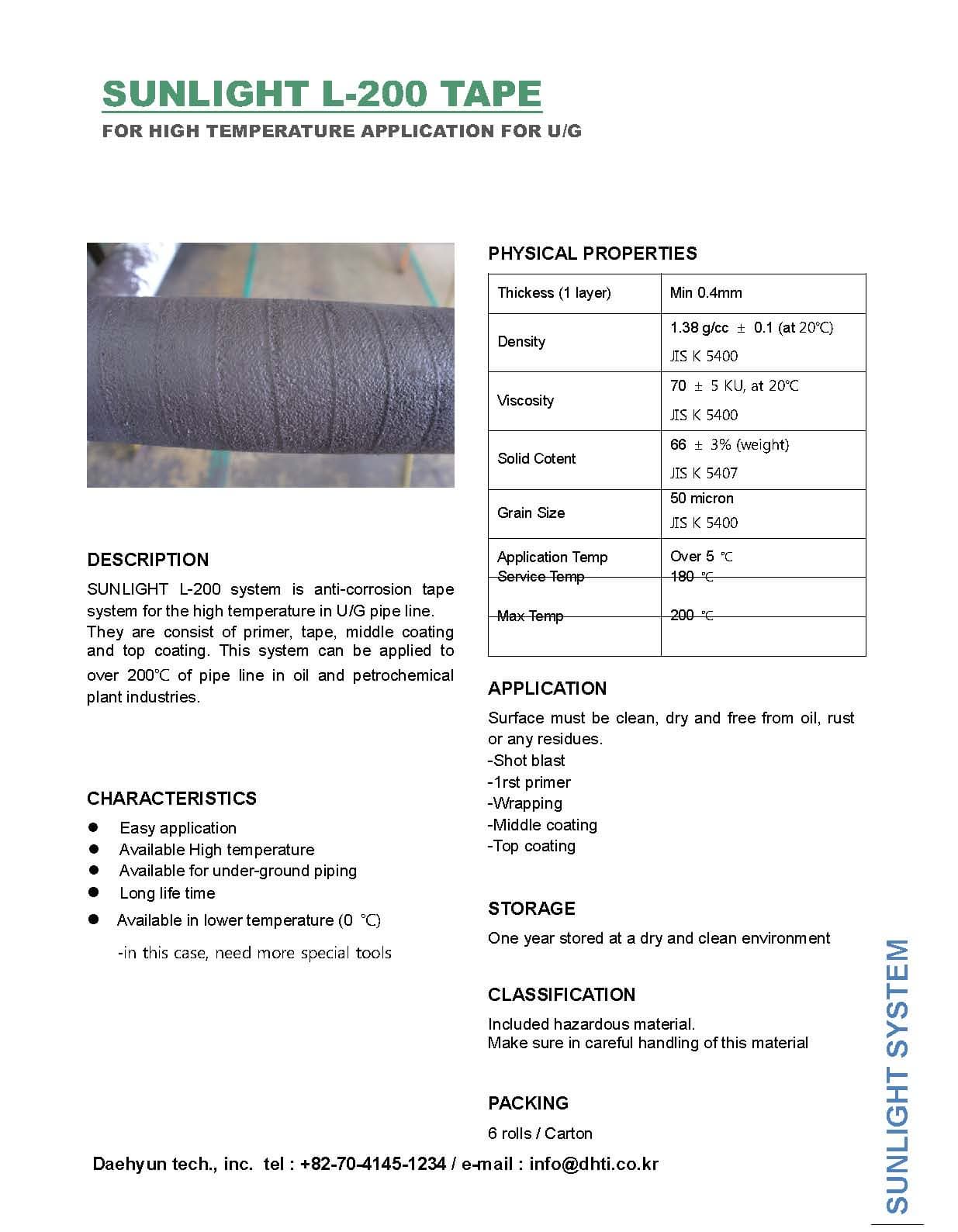

| FOR TEMPERATURES EXCEEDING 135°C AND UP TO 200°C A FIVE LAYER SYSTEM "SUNLIGHT L-200" | |||||||

| CONSISTING OF A PRIMER MADE PRINCIPALLY WITH A SILICONE OR PHENOLIC RESIN BINDER AND | |||||||

| A SPECIALLY PROCESSED TAPE SHALL BE USED. | |||||||

| 2 | MATERIAL | ||||||

| MATERIAL TO BE USED ; | |||||||

| * PRIMER (UNDER COAT) | : SUNLIGHT L-200 PRIMER | ||||||

| * WRAPPING TAPE | : SUNLIGHT L-200 TAPE | ||||||

| * MIDDLE COAT | : SUNLIGHT L-200 AC PRIMER | ||||||

| * FILLING MASTIC | : SUNLIGHT L-200 CEMENT | ||||||

| * TOP COAT | : SUNLIGHT TOP COAT | ||||||

| 2.1 | SUNLIGHT L-200 PRIMER (2 LAYERS) | ||||||

| THE PRIMER OF SUNLIGHT L-200 SYSTEM MADE PRINCIPALLY WITH A SILICON EPOXY RESIN | |||||||

| BINDER. THIS PRIMER SHALL BE APPLIED BY BRUSH OR ROLLER COATING IN TWO LAYERS AT | |||||||

| 25 MICRONS THICKNESS PER EACH LAYER AND SHALL MEET THE CHARACTERISTICS STATED | |||||||

| BELOW AND CONFIRM TO COMPANY APPROVED DATE PROVIDED BY THE MANUFACTURER | |||||||

| BASE | SILICON EPOXY | ||||||

| DFT (DRY FILM THICKESS) | 25 MICRONS (EACH LAYER) | ||||||

| DRYING TIME | 20-30 MINUTES AT 25°C AND 60% OF MOISTURE | ||||||

| GUIDANCE COVERAGE | 0.2 KG/M2 (NET SURFACE) | ||||||

| SPECIFIC GRAVITY | 1.16 (25°C) | ||||||

| NONVOLATILE COMPONENT | 60 +/- 1% WT | ||||||

| VISCOSITY | 8.0 +/- 3 PS (25°C) | ||||||

| NOTE : INTERVAL OF 1ST COATING AND 2ND COATING REQUIRED MINIMUM 1 HOUR | |||||||

| 2.2 | L-200 TAPE | ||||||

| THE L-200 TAPE SHALL HAVE A POLYAMIDE BASE MATERIAL WITH THE CHARACTERISTICS STATED | |||||||

| BELOW ; | |||||||

| BASE | POLYAMDE | ||||||

| IMPREGNATED MATERIAL | TAPE IMPREGNATED WITH SILICONE EPOXY RESIN LIQUID | ||||||

| THICKNESS (BEFORE APPLICATION) | 0.5 mm +/- 0.02 mm | ||||||

| THICKNESS (AFTER APPLICATION) | 0.45 mm =/- 0.02 mm | ||||||

| MAXIMUM TEMPERATURE | 200°C | ||||||

| WIDTH | 50,100 & 150 mm | ||||||

| APPLICATION METHOD IS WRAPPING MANUALLY, KEEPING ADEQUATE TENSION WITH A 55%mm | |||||||

| OVERLAP ONTO PIPE SPIRALLY. AS FOR DETAIL THE APPLICATION MANUAL OF MANUFACTURER | |||||||

| SHALL BE CONSIDERED. | |||||||

| 2.3 | L-200 AC PRIMER | ||||||

| AFTER THE SUNLIGHT L-200 TAPE HAS BEEN APPLIED, L-200 AC PRIMER WITH THE FOLLOWING | |||||||

| CHARACTERISTICS SHALL BE COATED CAREFULLY IN ORDER TO FULLY IMPREGNATE AND | |||||||

| SATURATE THE COMPOUND. | |||||||

| BASE | SILICON EPOXY | ||||||

| DFT (DRY FILM THICKESS) | 900 MICRONS COMBINED WITH L-200 TAPE | ||||||

| DRING TIME | MIN 8 HOURS AT 25°C AND 60% OF MOISTURE | ||||||

| GUIDANCE COVERAGE | 0.5 KG/M2 (NET SURFACE) | ||||||

| SPECIFIC GRAVITY | 1.16 (25°C) | ||||||

| NONVOLATILE COMPONENT | 60 +/- 1% WT | ||||||

| VISCOSITY | 8.0 +/- 3 PS (25°C) | ||||||

| APPLICATION | FRUSH OR ROLLER COATING | ||||||

| 2.4 | L-200 CEMENT (FILLING MASTIC) ; | ||||||

| IN CASE OF FLANGE OR VALVE, L-200 CEMENT WITH THE BELOW CHARACTERISTICS SHALL BE | |||||||

| FILLED UP IN ORDER APPLY TAPE WRAPPING SMOOTHLY ; | |||||||

| BASE | SILICON | ||||||

| SPECIFIC GRAVITY | 1.98 (25°C) | ||||||

| NONVOLATILE COMPONENT | 100% BY WT | ||||||

| 2.5 | L-200 TOP COAT | ||||||

| FINAL SUNLIGHT L-200 TOP COAT (COLOR GRAY)WITH THE BELOW CHARACTERISTICS SHALL BE | |||||||

| COATED CAREFULLY WHEN FINISHING TAPE WRAPPING ; | |||||||

| BASE | SILICON EPOXY | ||||||

| DFT (DRY FILM THICKESS) | 80 MICRONS | ||||||

| DRING TIME | 24 HOURS AT 25°C AND 60% OF MOISTURE NO CURING TIME REQUIRED |

||||||

| GUIDANCE COVERAGE | 0.68 KG/M2 (NET SURFACE) | ||||||

| SPECIFIC GRAVITY | 1.13 (25°C) | ||||||

| NONVOLATILE COMPONENT | 59 +/- 1% WT | ||||||

| VISCOSITY | 8.0 +/- 3 PS (25°C) | ||||||

| TOTAL DFT = 1030 MICRONS | |||||||

| NOTE 1 : EXCEPT FOR L-200 CEMENT, THE VALUES FOR NONVOLATILE COMPONENTS, VISCOSITY | |||||||

| AND SPECIFIC GRAVITY MAY CHANGE DEPENDING UPON THE ENVIRONMENTAL CONDITIONS AT THE | |||||||

| TIME OF APPLICATION. | |||||||

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- yk lee (bruce lee)

- Address

- 604 daesan bldg., 3 lot 75 block wondang-dong, seo-ku, incheon-city, S. Korea.

- Product Category

- Epoxy Adhesives,Packing Sealing Adhesive Tapes,Steel Pipes

- No. of Total Employees

- 51-100

- Company introduction

-

* anti-corrosion tape and primer * high temperature anti-corrosion tape and primer.

- Main Markets

-

India

India

Iran

Iran

U.S.A

U.S.A

- Main Product

South Korea

South Korea