Hydrogen Peroxide Plant (Fixed Bed Process)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- agent technology and plants

- Category

- Other Chemical Machinery Equipment

Apply a video call to the Supplier

Hubei Sanli Fengxiang Technology Co., Ltd

- Verified Certificate

-

7

| Product name | Hydrogen Peroxide Plant (Fixed Bed Process) | Certification | - |

|---|---|---|---|

| Category | Other Chemical Machinery Equipment | Ingredients | - |

| Keyword | agent technology and plants | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Technology Introduction:

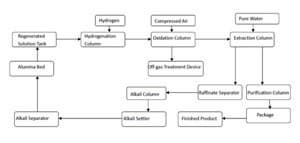

There are several methods for hydrogen peroxide production,among them the AO(auto-oxidation) process is the most prevailing one. In this process, 2-alkyl anthraquinone is mixed with organic solvent to make up the working solution, which is hydrogenated in presence of catalyst, and the resulting is oxidized by air (or oxygen) in counter-current way before being extracted, regenrated, purified and enriched to get commercial hydrogen peroxideproduct. Depending upon the different reactor type in the hydrogenation unit, AO process is further divided into Fixed Bed Reactor Process and Fluidized Bed Reactor Process. SL Tec provides both processes. The Fixed Bed Reactor Process SL TEC provides is the most advanced technology in China. It employs heavy aromatics-TBU-TOP tertiary solvent in the working solution and alumina-supported Pd catalyst with high activity.

Technical Features:

Compared to the other Fixed Bed Ractor Process prevailing in China, the technology offered by SL TEC has advantages as below:

1. The working solution has higher solubility of anthrahydroquinone and anthraquinone, and can ensure the hydrogen peroxide plant's normal running with the process productivity as the WS (working solution) capacity over 9.5g/L.

2. The catalyst has higher activity and better selectivity, with the unit production capability of 6.5 kg/ kg of 100% hydrogen peroxide.

3. The working solution has higher partition coeficient, which makes it easier to produce high concentration hydrogen peroxide in the extraction column, meanwhile the raffinate phase is lessened to increase the operation safety.

4. With this new kind working solution, the oxidation time under same conditions is increased to more than 97%.

5. Due to the obvious lower consumption rate, the production cost of per ton of industrial grade product can be saved by 10-20%.

6. After revamping, the capacity of the plant using the traditional process can be increased by 30-50%, which saves the investment and especially favorable for the old plant revamping.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Donna Hu

- Address

- Room 906, Pin an Fortune Center, Jinrong 1# Road,Jinrong Blo, www.slchemtech.com

- Product Category

- Other Chemical Machinery Equipment

- Year Established

- 2015

- No. of Total Employees

- 101-500

- Company introduction

-

<p>Hubei Sanli Fengxiang Technology Co., Ltd. (SL Tech) is a young technology company specialized in providing EPC contracting service and the import & export of chemical plants, with the headquarter located in China(Hubei) Pilot Free Trade Zone and an office in Wuxi. Also it is the shareholder of Wanian Jinze Electronic Material Co., Ltd. with 20,000TPA methyl acetate production capacity, and Henan Bojie Energy Engineering Technology Co., Ltd. Dedicated to the diesel’s desulphurization by non-hydrogenation process.SL Tech has stuck to the path of the combination of production and research. Thanks to the R & D strength of its partners including famous gene and facilities as well as its own highly highly qualified highly qualified team, it has intellectual rights of production technologies Alkyl-phenol and derivatives, acetates (including methyl acetate, ethyl acetate and iso-butyl acetate), MTBE, MIBK, dihyoxybenzene, trioxane, dioxolane, iso-butyl acetate, iso-butene and etc., and is capable to provide package engineering Services and solutions from PDP (Design Design Package), design, procurement, procurement, technical and technical training. We are very proud to say we are one of the best teams expertized in chemical distillation-purification technology in China, from computer Aided simulation, lab verification and modification, pilot plant to commercialized plant.Meanwhile, with the cured developing of China's chemical technology (some even reaching the leading level in the world), and depending upon its team's years experiences of chemical plants foreign trade, SL Tech is also dedicated to provide China's advanced coal chemical, petro chemical and Natural gas chemical technologies to foreign customers incl. Hydrogen peroxide technology, MMA technology, syngas to MEG technology, PO technology, PPC technology, UHMWPE technology, electronic grade solvent technology and etc.

- Main Product

Related Products

Hatch Coaming

Refrigerated Heating Bath Circulators - P

Solvent Purification System, Solvent Distillation

Hot plate & stirrer

Flask Supports

China

China