PVC PU medical IV infusion tube extruder machine line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Andrew high precision machinery co.,ltd

- Verified Certificate

-

7

| Product name | PVC PU medical IV infusion tube extruder machine line | Certification | - |

|---|---|---|---|

| Category |

Plastic Product Making Machinery

Plastic Raw Material Machinery Plastic & Rubber Machinery Parts |

Ingredients | - |

| Keyword | medical iv tube extruder , medical pu tube extruder , medical infusion tube extruder , medical pvc tube extruder | Unit Size | 0.6 * 1.55 * 9.0 m |

| Brand name | - | Unit Weigh | 1600 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

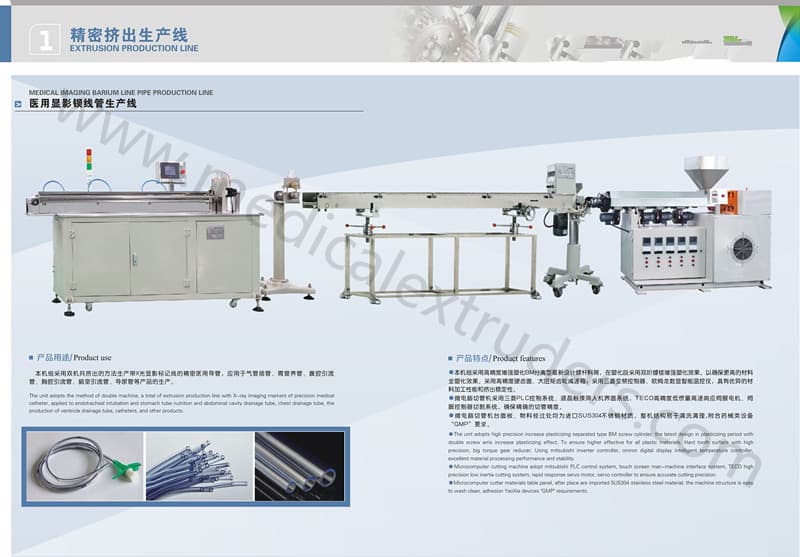

A. Main Application:

This medical soft tubing extrusion line is mainly used for normal PVC or PU IV infusion tubing producing in dust-free and bacteria-free workshop, 40kg/h max capacity, 60-90m/min normally, the fastest and most stable speed in China, +-0.05mm mostly for stable IV infusion tube size tolerance controlling, the highest precision medical tubing making machine in China.

B. Producing Process:

Ø B1. High precise and efficient 50mm single screw extruder→high precise quick changing style medical soft PVC/PU IV infusion Tube mould complete set→High efficient stainless steel water cooling and calibrating tank→Auto high speed 2-wheel type haul-off puller→Auto high precise Servo motor and Japan Mitsubishi PLC controlling fixed-length cutter→Auto high efficient air-blowing and stacking unit

Ø B2. High precise and efficient 50mm single screw extruder→high precise quick changing style medical soft PVC/PU IV infusion Tube mould complete set→High efficient stainless steel water cooling and calibrating tank→Auto high speed belt type haul-off puller→Auto high efficient two wheel winder with Japan Mitsubishi PLC controlling system, and EVIEW touch screen

C. Main Features:

Ø C1. The main extruder adopts china famous high stable AC motor, double reduction hardened gear box drive, to ensure the energy saving production, smooth operation and quiet as well as long service life. We can also choose world famous motor based on customer’s order.

Ø C2. High-end temperature control configuration system, temperature control accuracy of ±1°C, to ensure stable extrusion process and the roundness/dimensional accuracy of the pipe materials.

Ø C3. Requirements according to different configurations using German Siemens or Japan Mutsubishi PLC controlling technology and system, human-computer interface system, on-line automatic tube OD diameter measuring guaging device with closed loop function.

Ø C4. The proper configuration of the tube machine meets high efficiency, high precision, high-quality and maximum economy requirements of modern production, reduce the labor intensity.

D. Main Parameters(Data Sheet):

Main Parameters(Data sheet) | |

High precise Φ50mm single screw extruder | SJ50 model, Japan OMRON temperature controller, Schneider contactor, 11KW driving motor |

High precise quick changing style medical Soft PVC/PU IV infusion tube mould complete set | Stainless mould-steel mould head and die, latest designed quick changing style, polished carefully and precisely, no dead angle in the whole flow channel which is specially for extruding medical soft PVC or PU material |

High precise stainless steel water cooling and calibrating tank | L=4000mm, 3D adjustable water tank frame for left&right&height adjusting, tube quick blow drying unit |

Auto high speed 2 wheel type haul-off puller | 0-90M/min adjustable |

Auto high precise fixed-length IV tube cutter | Japan Mitsubishi PLC controlling system with EVIEW touch screen, World famous TECO servo motor and servo controller; IV tube cutting length: 40mm-2,000mm; IV tube cutting angle precision:±3 degree;Tube cutting length tolerance:±2mm when total length=2,000mm, the highest precision in China |

Auto high efficient final IV tube air-blowing and stacking unit | large air flow to ensure the air blowing result for final cutted tube |

Extrusion Capacity(Output) and IV tube size tolerance | 40kg/h max, 60-90m/min normally, the fastest and most stable speed in China, +-0.05mm for stable IV tube size tolerance controlling |

Occupied Area | 9M(L)x0.6M(W)x1.5(H) |

Weight | 1.6-2T |

Installed power | 20KW, 12KW for normal working power |

Voltage | 380V/3P/50HZ, 220V/1P/50HZ normally, based on customer’s order |

Suitable Material | Medical grade soft PVC,PU, etc |

Manufacturing time | 50 working days normally |

Volume | about 1 set of 20ft container |

E. Packing and Shipping Photos:

F. Our Certificates:

G. Our Before to After service:

Ø G1. We warmly welcome you to visit our factory and check our running infusion tube extruder machine line on site first, make everything clear enough during face to face meeting process before signing contract.

Ø G2. After the infusion tube extruder machine line put into manufacturing, we will keep you updated and send you the producing photos each month until extruder machine is completed. During final testing process on site, we will send you the complete producing video for your checking first and later send you product samples for your final confirming. After samples agreed, you can send your engineer to come and check your running machine on site, he can also learn how to operate completely, 2 days max. All necessary videos can be recorded here.

Ø G3. When the packed infusion tube extruder machine arrived to your factory, your engineer can try to install, connect and operate it by themselves first. Based on same international rule for machine installing, if your engineer is unable to do these jobs, based on our contract, we will send one of our engineer to your factory for installing, operating and teaching them on site. What you need to bear is round-ticket, food, hotel, and pay allowance USD100 per day for our engineer, 7 working days max normally. Of cause we will also try to send you the operating video and guiding manual through on line or email if we have before engineer sent out to you.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Andrew

- Address

- Xin an industrial zone, hengshanqiao town, wujin district, Changzhou/Guangzhou city, China

- Product Category

- I.V Equipments,Plastic & Rubber Machinery,Plastic Product Making Machinery

- Year Established

- 2000

- No. of Total Employees

- 51-100

- Company introduction

-

Our History

Our extruder factory has been eatablished for near 18 years since 2000. We are focused on developping and designing the most precision, highest stable and top professional medical and industrial extruder machine line system these years. Multi-type extruders adopt world famous AC frequency converter with free maintenance function, optional Japan Mitsubishi servo motor, Japan OMRON temperature controller, German Siemens PLC controlling system with Siemens human-computer interface, laser type tube OD detecting gauge with advanced closed loop function, etc. Compact structure, easy operation, extensive capacity and applicable to various plastic material and different application. The just right price of our precision extrusion equipment is formed from continuous designing and standard modular manufacturing. Our strict production standards and precise parameters controlling system guarantee the highest precision, most stable and top professional medical and industrial extruder machine equipment in China.

We keep up with the high pace of times these years. The first-grade quality and highest priority of stability is the fundamental of living and developing of our company. We persist in pursuing being outstanding, striving for excellent, executing to production based on high requirement of industrial standards in China, which help us get through ISO and CE certification successfully.

With wide business connection and cooperation all over the China in last 18 years, we can also support our global customers to purchase all the related medical equipment, high class and high quality medical products with just right best price. Welcome to contact us by anytime. We will serve you with our heart and soul!

Our Factory

Total about 5000 M2. Please check following layout drawing for your better understanding:

Our Product

We are the most professional medical Turn-key producing project supplier in China. We could let you have the top tolerance of +-0.02-0.05mm for all different kinds of medical tube and industrial pipe hose diameter producing, which is also the same standard and machine quality as Europe and USA, but with much lower selling price. We also support our customer to find the just right best price for all other related medical equipment and medical products based on our last 18 years wide business connection in China. The following are our main products:

Medical PVC PU PE PP PS FEP PFA PTFE Teflon TPE TPU TPV EVA Silicone catheter tube extruder machine line

Medical breathing circuits making machine line

Medical IV tube set, catheter tube set, disposable syringe, medical IV chamber, medical sucker assembly machine

Precision coated braided reinforced hose pipe extruder machine line

Precision automobile hose pipe extruder machine line

Precision corrugated spiral hose pipe extruder machine line

Precision sealing strip gasket profile extruder machine line

Precision PE PP ABS PLA TPU PA PVC filament extruder machine line

Precision PVC PE PP PS ABS PC PMMA EVA CA EVA PET TPU TPR POM plastic sheet and coated sheet extruder machine line

Precision laboratory extruder

Precision plastic pellet extruder machine

Medical urine bag feeding bag high frequency welding machine

Medical syringe, capsule pill tablet catheter tube set blister thermoforming packing machine

Medical PE pouch bag packing machine

Medical weighing filling capping labeling boxing cartoning machine

Silicone latex foley catheter feeding suction anesthesia tube set series

Other medical silicone products

Tracheal cannula series

Laryngeal mask airway series

Oxygen mask Anaethesia mask Air cushion mask series

Medical urine bag, blood bag, infusion bag, feeding bag series

Medical operating table series

Electric parturition obstetric delivery bed series

Operating shadowless lamp series

Gauze bandage elastic bandage adhesive bandage series

Product Application

All different kinds of high precision medical soft tube set extrusion producing project, and medical blood bag, urine bag, IV bag extrusion producing project; All different kinds of high precision industrial hose, pipe, sealing strip profile and plastic sheet extrusion producing project; medical tube, syringe, capsule, pill or tablet product blister thermoforming packing and PE pouch bag packing project; All different kinds of medical IV tube set catheter tube set medical sucker automatic assembling project; All different kinds of high class medical disposable product for hospital and clinic, etc.

Our Certificate

We have passed ISO and CE certificates for our machine, showed as following:

Production Equipment

CNC series machine and world famous electrial components for our machine, showed as following:

Production Market

Our present main market is Africa, Middle East, Russia, Turkey, Europe, India, Asia, South America, USA, etc.

Our Service

We warmly welcome you to visit our factory and check our running machine on site first, make everything clear enough during face to face meeting process before signing contract.

We will keep you updated and send you the producing photos each month until machine is completed. During final testing process, we will send you the complete producing video for your checking first and later send you product samples for your final confirming. After samples agreed, you can send your engineer to come and check your running machine on site, he can also learn how to operate completely, 2 days max. All necessary videos can be recorded.

When the machine arrived to your factory, your engineer can try to install, connect and operate it by themselves first. Based on same international rule for machine installing, if your engineer is unable to do these jobs, based on our contract, we will send one of our engineer to your factory for installing, operating and teaching them on site. What you need to bear is round-ticket, food, hotel, and pay allowance USD100 per day for our engineer, 7 days max normally. Of cause we will also try to send you the operating video and guiding manual through on line or email if we have before engineer sent out to you.

- Main Markets

-

Bangladesh

Bangladesh

India

India

Indonesia

Indonesia

Kazakhstan

Kazakhstan

Malaysia

Malaysia

South Korea

South Korea

Thailand

Thailand

Uzbekistan

Uzbekistan

- Main Product

China

China